Carbon oxide ball doped solid polymer electrolyte membrane and preparation method and application thereof

A solid polymer and electrolyte membrane technology, applied in the field of lithium-ion batteries, can solve problems such as explosion, safety hazards that cannot be eradicated, and fire, and achieve the effects of simplifying the process, enhancing electrochemical stability, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a solid polymer electrolyte membrane, which includes the following steps:

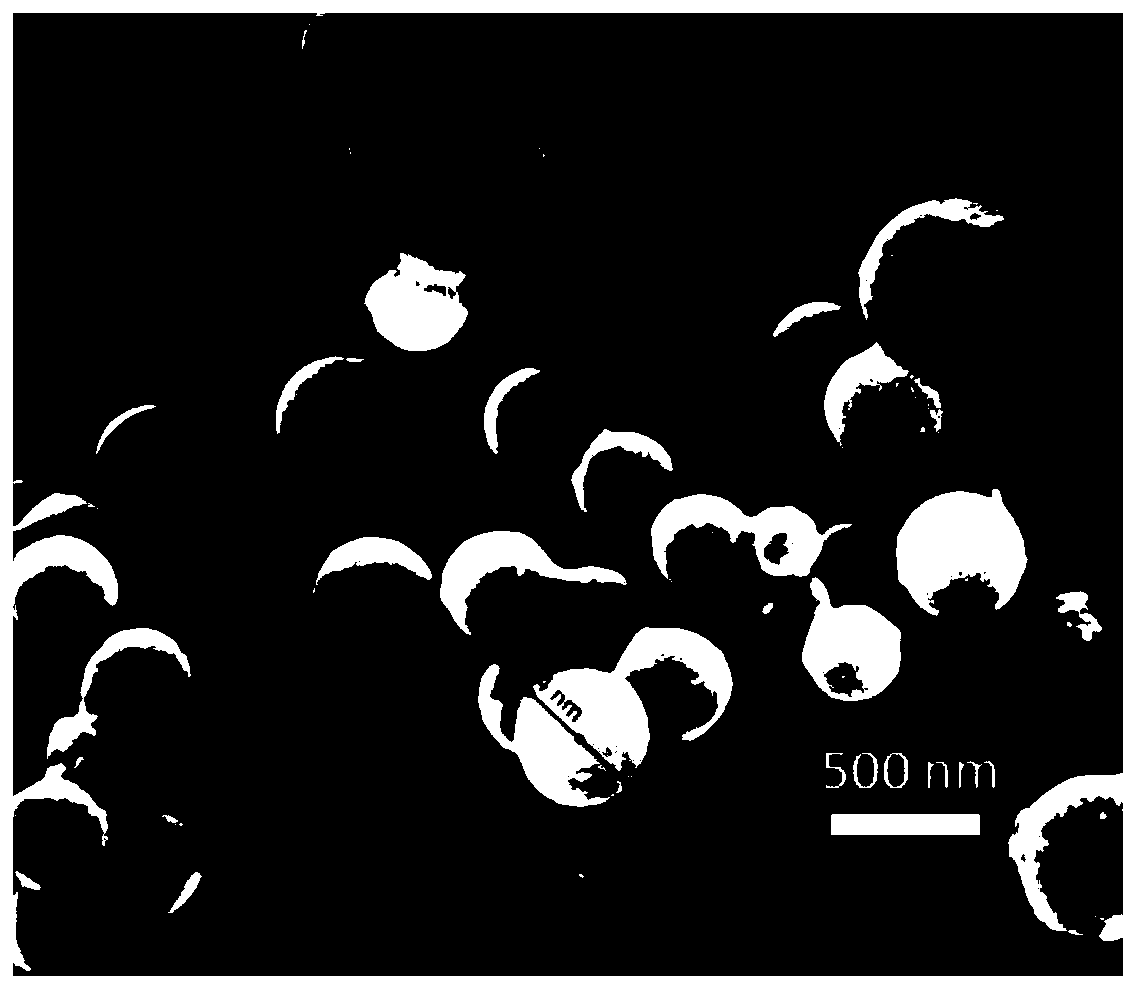

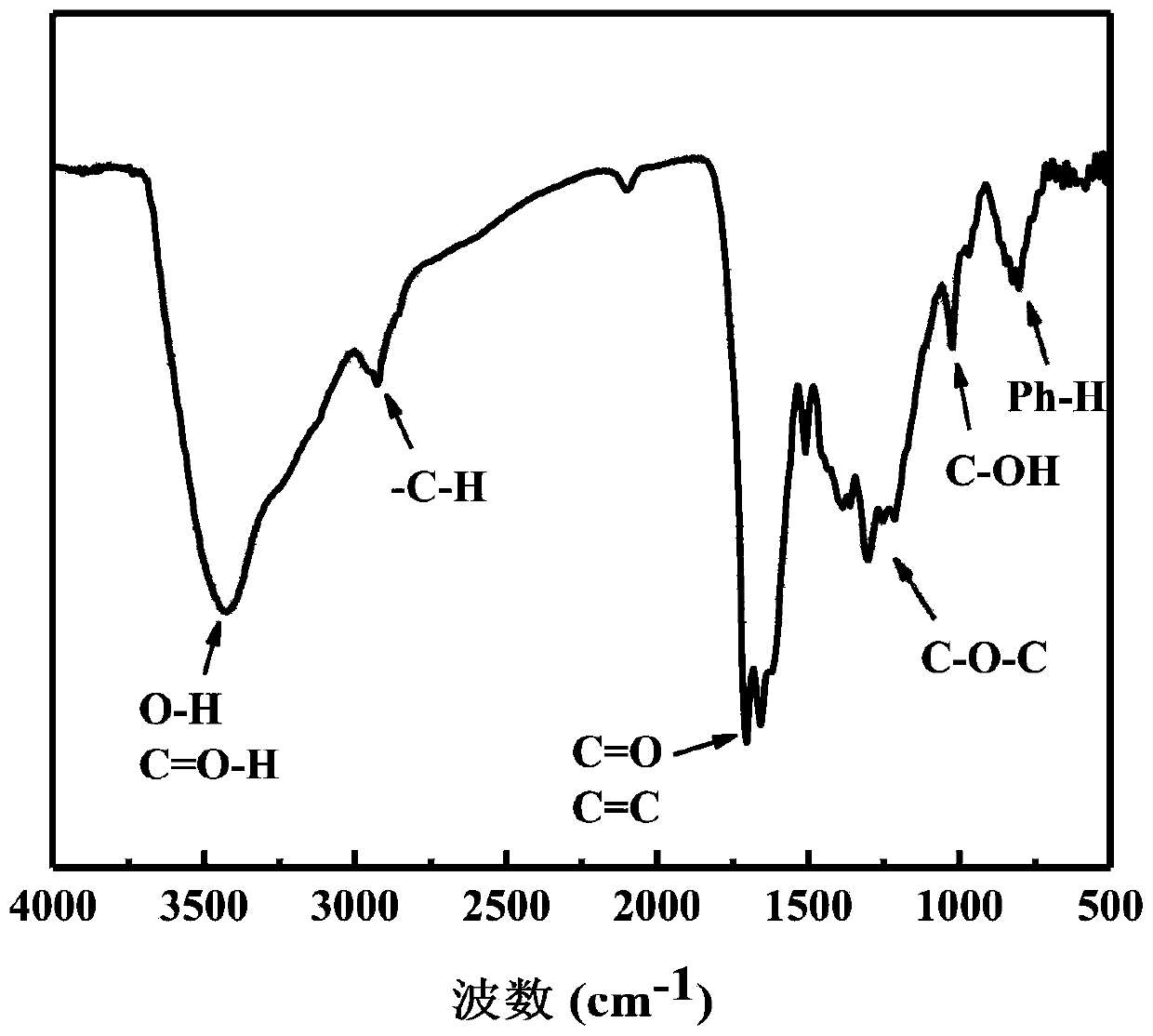

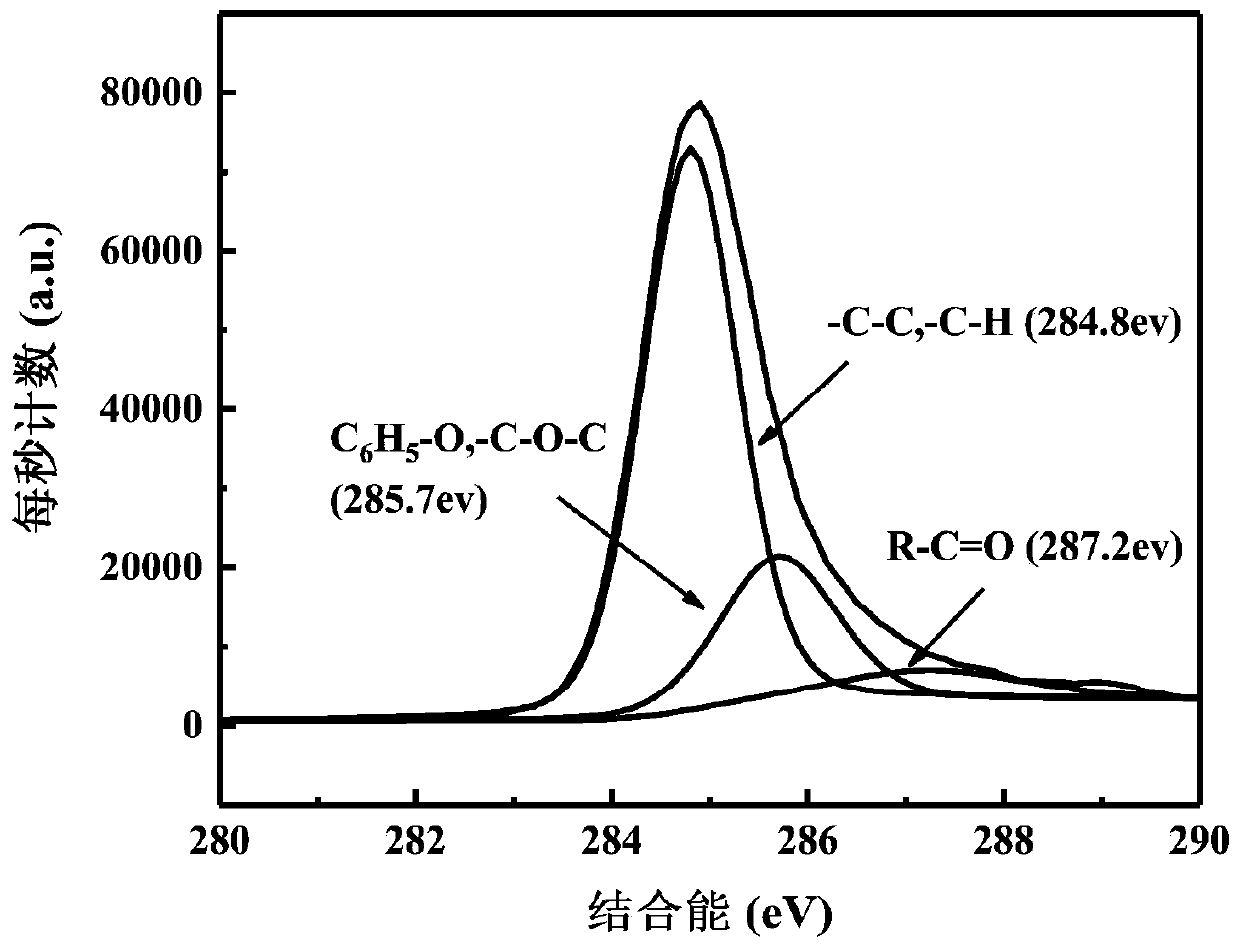

[0046] Step 1, adding carbon dioxide spheres to the organic solvent N,N-dimethylformamide (DMF) for ultrasonication, stirring magnetically to a uniform solution, and then adding the polymer matrix polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP ) stirred until uniformly obtained mixed solution;

[0047] Wherein, the mass ratio of the carbon dioxide spheres, the organic solvent DMF and the polymer matrix PVDF-HFP is 0.05:10:1;

[0048] Step 2: Pour the mixed solution into a smooth PTFE surface dish with a diameter of 10 cm, form a film by pouring, control the film thickness by pouring the mixed solution, control the pouring amount of the solution at about 8 to 10 g, and then After normal drying at 60°C for 6 hours, put it into a vacuum drying oven at 60°C for 24 hours to obtain a solid polymer electrolyte membrane with a thickness of about 50...

Embodiment 2

[0058] This embodiment provides the application expansion of solid polymer electrolyte membrane, in Li-O 2 The application in the battery, it comprises the following steps:

[0059] Step 1, adding carbon dioxide spheres to the organic solvent N,N-dimethylformamide (DMF) for ultrasonication, stirring magnetically to a uniform solution, and then adding the polymer matrix polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP ) stirred until uniformly obtained mixed solution;

[0060] Wherein, the mass ratio of the carbon dioxide spheres, the organic solvent DMF and the polymer matrix PVDF-HFP is 0.05:15:1;

[0061] Step 2: Pour the mixed solution into a smooth PTFE surface dish with a diameter of 10 cm, form a film by pouring, control the film thickness by pouring the mixed solution, control the pouring amount of the solution at about 8 to 10 g, and then After normal drying at 60°C for 6 hours, put it into a vacuum drying oven at 60°C for 24 hours to obtain a solid polymer elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com