Preparation method of polymer electrolyte composite membrane for solid-state battery

A solid-state battery and polymer technology, applied in the field of lithium-ion battery separator, can solve the problems of insufficiency and low lithium-ion conductivity, and achieve the effects of easy batch production, accelerated cation conduction, and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation of ZIF-8

[0036] Weigh 2.974g (10.0mmol) of zinc nitrate hexahydrate, dissolve it in 200mL of methanol, and dissolve it completely by ultrasonication for 10 minutes; Dissolve, pour the obtained 2-methylimidazole solution into the zinc nitrate hexahydrate solution and stir for 2 hours at a stirring speed of 500r / min. The above product is centrifuged three times and washed with methanol three times at 8000r / min for 10 minutes. The centrifuged product is dried at 80°C for 24 Hours, ZIF-8 white powder was obtained.

[0037] 3. Preparation of ZIF-67

[0038]Weigh 1.456g of cobalt nitrate hexahydrate and dissolve it into 50mL DMF, and dissolve 3.28g of 2-methylimidazole into 50mL DMF, respectively, and ultrasonically dissolve them. After the dissolution is complete, pour the 2-methylimidazole solution into cobalt nitrate hexahydrate and stir for 6 hours, the stirring speed was 500r / min, the centrifuged product was centrifugally washed with methanol three tim...

Embodiment 1

[0044] A polymer electrolyte composite membrane for a solid-state battery, the specific preparation steps are as follows:

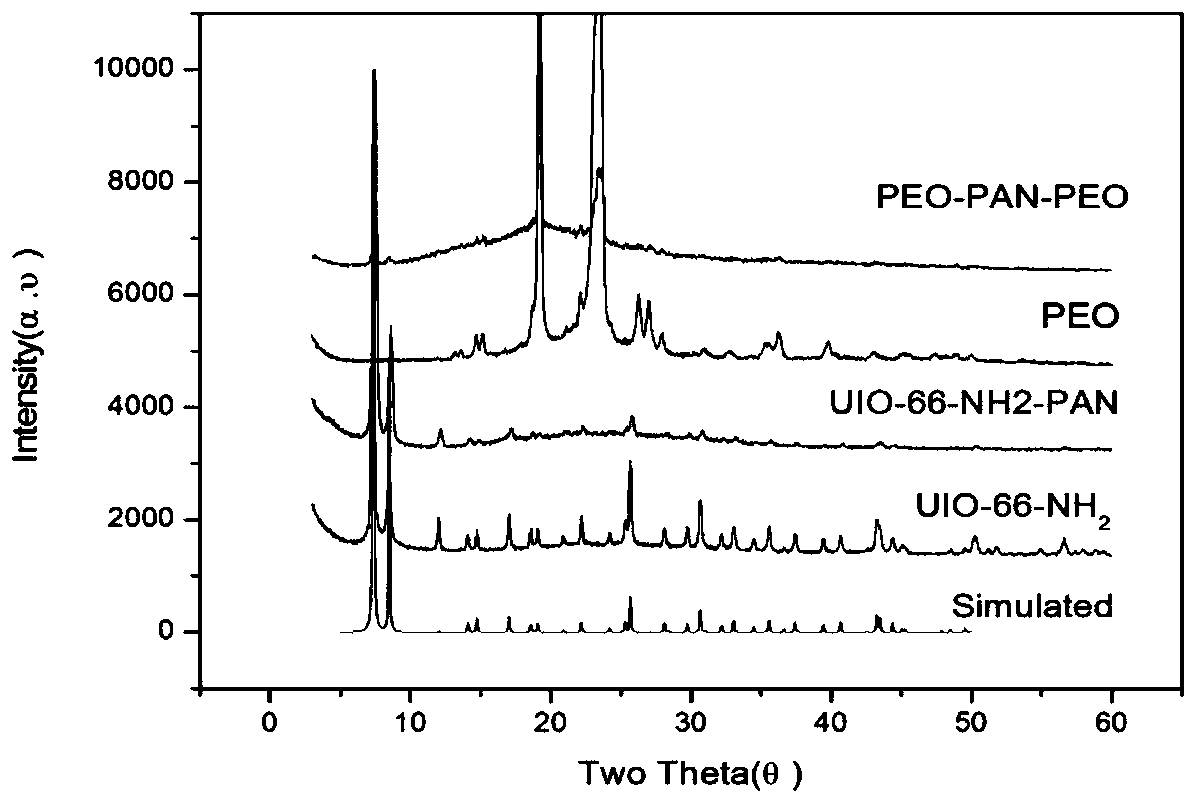

[0045] 1. Preparation of metal-organic framework / fiber composite membrane: Under the condition that the ambient temperature is 20±2°C and the air humidity is 15-25%, take 5mL UIO-66-NH2 / PAN spinning solution (0.6g UIO-66- NH2 and 0.4g PAN (Mv=150000) were completely dissolved in N-N dimethylformamide, stirred for 24 hours) into a 5mL syringe, using a needle with an inner diameter of 0.6mm, the receiver rotation speed was 15mm / min, and the spinning was advanced The speed is 0.15mm / min, the positive pressure of the needle is 9.6kV, the negative pressure of the receiver aluminum foil is 2kV, the distance from the needle to the aluminum foil is 15cm, and the metal organic framework / fiber composite film is made by electrospinning, abbreviated as UIO-66-NH2 spinning film , by adjusting the aperture size of the needle and the distance from the needle to the drum...

Embodiment 2

[0053] A polymer electrolyte composite membrane for a solid-state battery, the specific preparation steps are as follows:

[0054] 1. Preparation of metal-organic framework / fiber composite membrane: under the condition that the ambient temperature is 20±2°C and the air humidity is 15-25%, take 5mL ZIF-8 / PAN spinning solution (0.6g ZIF-8 and 0.4 g PAN (Mv=150000) completely dissolved in N-N dimethylformamide) was injected into a 5mL syringe, using a needle with an inner diameter of 0.6mm, the receiver rotation speed was 15mm / min, and the spinning speed was 0.1mm / min. The positive pressure is 7.2kV, the negative pressure of the receiver aluminum foil is -2kV, the distance from the needle to the aluminum foil is 15cm, and the metal organic framework / fiber composite film is made by electrospinning, abbreviated as UIO-66-NH2 spinning film, with a thickness of 90μm;

[0055] 2. Preparation of PEO / Li(TFSI) composite membrane: Weigh 3.25g of PEO (Mv=1000000), dissolve it in 75g of ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com