Two-dimensional nanostructure electrolyte additive, preparation method and application

A two-dimensional nanostructure, electrolyte additive technology, applied in the fields of electrolyte battery manufacturing, nanotechnology, secondary batteries, etc., can solve problems such as the decrease of additive concentration and the inability to meet long-term stability, and achieve better thickness control and improvement. Conductivity and ion mobility number, the effect of enhancing interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the two-dimensional nanostructure electrolyte additive comprises the following steps:

[0028] (1) Exfoliate organic or inorganic bulk materials into two-dimensional nanosheets with a thickness of less than 10 nanometers by ball milling, ultrasonic dispersion or chemical methods. Wherein, the time for the ball milling is 10h-20h; the time for the ultrasonic dispersion is 1h-10h; the dispersant used for the ultrasonic dispersion is water, ethanol, isopropanol, N,N-dimethylformamide, N- One or more of methylpyrrolidone.

[0029] (2) adding the two-dimensional nanosheets into deionized water to disperse evenly to obtain a two-dimensional nanosheet dispersion, and freeze-drying the two-dimensional nanosheet dispersion to obtain a two-dimensional nanostructure electrolyte additive. Wherein, before the freeze-drying of the two-dimensional nanosheet dispersion, the two-dimensional nanosheet dispersion needs to be vacuum filtered.

[0030] The presen...

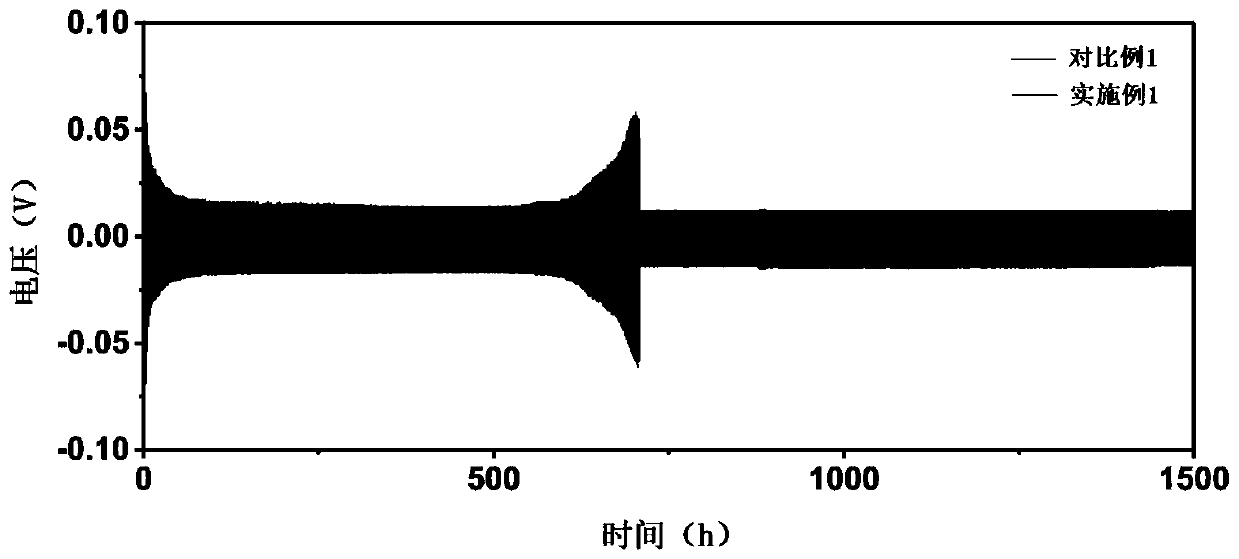

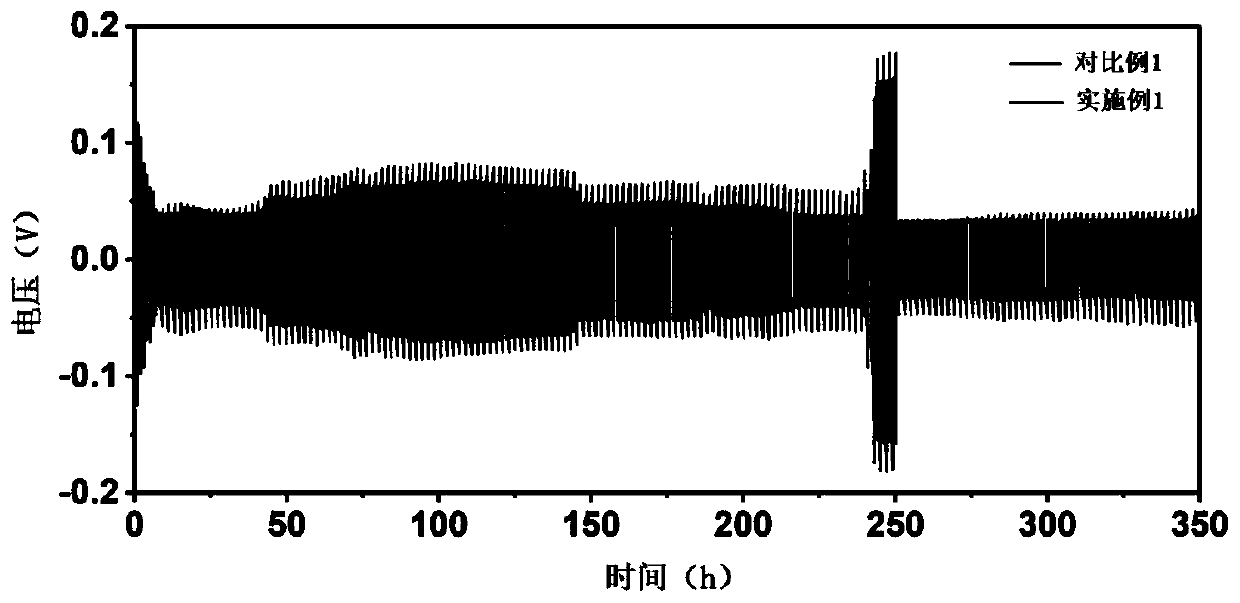

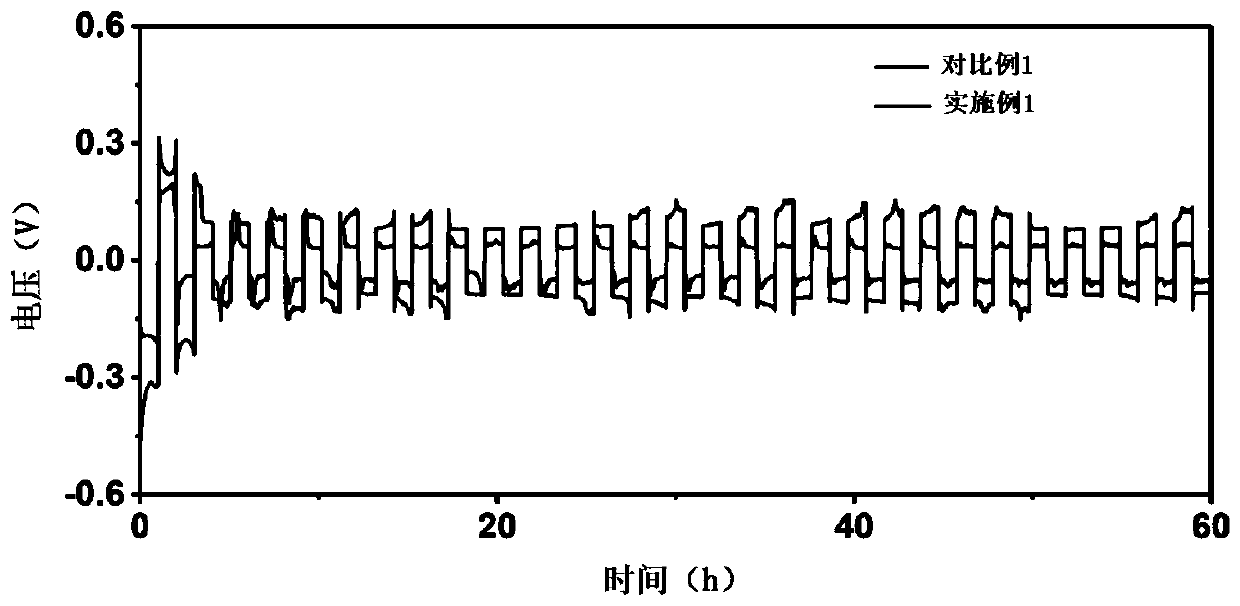

Embodiment 1

[0033] 1. Preparation of Additives

[0034] The preparation method of the additive of the present embodiment comprises the steps:

[0035] (1) Add 2g of hexagonal boron nitride and 120g of urea into a 150mL polytetrafluoroethylene ball mill jar, seal and ball mill at room temperature at 500rpm for 24h.

[0036] (2) Add the mixture obtained in step (1) into 1 L of deionized water, and ultrasonically disperse for 1 h.

[0037] (3) Vacuum filter the dispersion obtained in step (2), wash twice with deionized water, and freeze-dry to obtain the final product.

[0038] The additive in this embodiment is a white powder, which can form a colloid in the electrolyte, and is added at a mass ratio of 0.7%.

[0039] 2. Electrolyte Preparation

[0040] Mix DOL and DME at a volume ratio of 1:1, then add LiTFSI and LiNO 3 , formulated with 1M LiTFSI and 2wt% LiNO 3 After dissolving, add the above-mentioned additives, mix according to the mass ratio of 99.3:0.7, and stir overnight to obta...

Embodiment 2

[0043] The preparation method of the additive is basically the same as in Example 1, but sucrose is used instead of urea ball milling. In addition, the additive and the electrolyte were mixed in a mass ratio of 99:1, the electrolyte salt was 1M LiTFSI, and the organic solvent was DOL+DME (1:1, vol). The lithium metal symmetric battery was also tested, and the amount of electrolyte was not changed. Test its room temperature cycle performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com