Sticky antibacterial repair material and preparation method and application thereof

A repair material and a sticky technology, which are applied in the field of sticky antibacterial repair materials and their preparation, can solve the problems of drug rubbing off, difficulty in sticking to the affected area, etc., and achieve accelerated healing, good tissue compatibility, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention also provides a preparation method of an adhesive antibacterial restoration material, and the preparation method includes the following steps.

[0036] Step A:

[0037] Under sterile conditions, mix purified water, humectant and D-panthenol evenly, add modified chitosan and forming agent and mix evenly, then add bioactive glass, preservatives and functional additives and mix evenly to obtain a mixed solution, Use a pH regulator to adjust the pH value of the mixture to 3.5-5.5, sterilize it at 120-125°C and cool it for later use; or, under sterile conditions, add a forming agent to purified water and heat, mix and dissolve, After cooling, add humectant and D-panthenol and mix evenly, then add modified chitosan and mix evenly, then add bioactive glass, preservatives and functional additives and mix evenly to obtain a mixed solution, and use a pH regulator to adjust the pH of the mixed solution. Adjust the pH value to 3.5-5.5, sterilize at 120-125°C and cool...

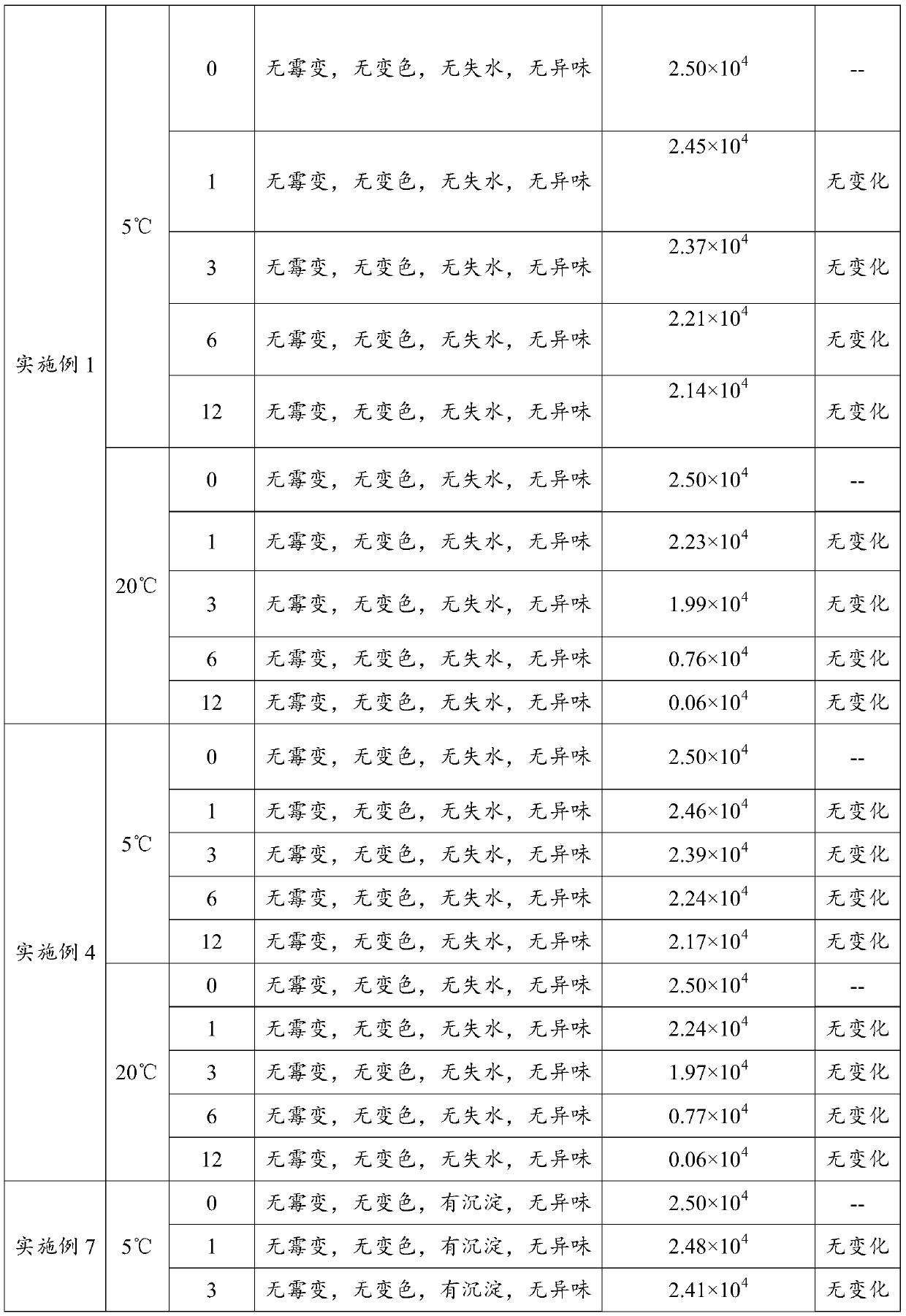

Embodiment 1

[0048] In this example, an adhesive antibacterial repair film for the treatment of oral ulcers was obtained, which was prepared according to the following mass percentages: mussel mucin 0.18%, D-panthenol 0.2%, modified chitosan 10%, bioactive glass 0.5%, 10% forming agent, 30% moisturizing agent, 0.5% preservative, 4% protein protecting agent, 5% pH regulator, 13% functional auxiliary agent and the balance of purified water.

[0049] The molding agent is polyvinyl alcohol, the humectant is glycerin and dodecyl, the preservative is dehydroacetic acid, the protein protection agent is human serum albumin, the pH regulator is ethyl acetate, and the modified chitosan is chitosan quaternary Ammonium salt, functional additives are a mixture of trace element solutions including zinc, iron, selenium, copper, etc., hyaluronic acid and urea sac.

[0050] The preparation of this embodiment comprises the following steps:

[0051] (1) Sterilize all instruments;

[0052] (2) Dissolve poly...

Embodiment 2

[0056] In this example, the sticky antibacterial repair film for the treatment of oral ulcers was prepared according to the following mass percentages: mussel mucin 0.16%, D-panthenol 2%, modified chitosan 5%, bioactive glass 5%, 6% forming agent, 25% moisturizing agent, 0.7% preservative, 3% protein protecting agent, 2.6% pH regulator, 20% functional additive and the balance of purified water.

[0057] The forming agent is polyvinyl alcohol, the moisturizing agent is sorbitol and dodecyl, the preservative is dehydroacetic acid, the protein protection agent is human serum albumin, the pH regulator is acetic acid, and the modified chitosan is carboxymethyl chitosan , The functional aid is a mixture of trace element solutions including zinc, iron, selenium, copper, etc., hyaluronic acid and urea capsules.

[0058] The preparation of this embodiment comprises the following steps:

[0059] (1) Sterilize all instruments;

[0060] (2) Dissolve polyvinyl alcohol in purified water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com