Preparation method of insulation medium with improved energy density

A technology of insulating medium and energy storage density, applied in insulators, electrical components, circuits, etc., can solve problems such as no one in the research field, and achieve the effect of improving energy storage density, low process difficulty, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

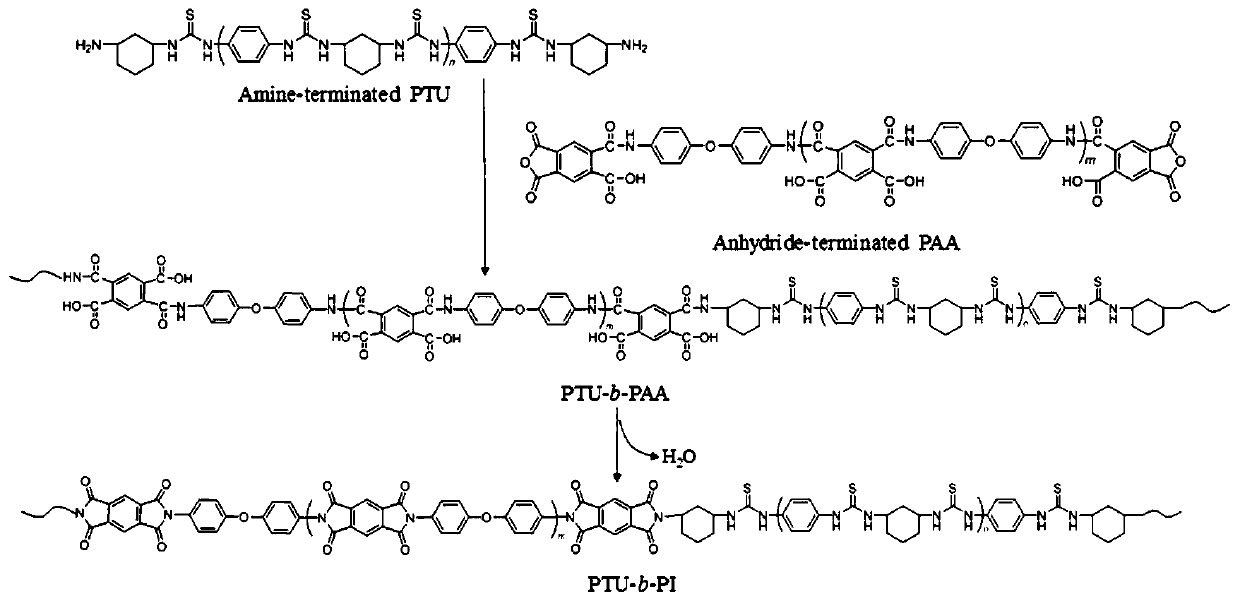

[0025] A kind of insulating medium preparation method that improves energy storage density of the present invention, comprises the following steps:

[0026] 1) 1,4-phenylenediisothiocyanate is completely dissolved in a polar solvent, then 1,3-cyclohexanediamine is added, and reacted for 3-6 hours under nitrogen environment and room temperature to obtain amino-terminated poly Thiourea precursor.

[0027] Wherein, the ratio of 1,4-phenylene diisothiocyanate to polar solvent is 0.96mmol:1-4mL.

[0028] The total substance amount of pyromellitic dianhydride and 1,4-phenylene diisothiocyanate and the total substance amount of 1,3-cyclohexanediamine and 4,4'-diaminodiphenyl ether same.

[0029] The amount ratio of 1,4-benzenediisothiocyanate to 1,3-cyclohexanediamine was 0.96:1.

[0030] The amount ratio of 4,4'-diaminodiphenyl ether to pyromellitic dianhydride was 0.96:1.

[0031] The polar solvent is N,N-dimethylacetamide (DMAc) or N,N-dimethylformamide (DMF).

[0032] 2) Add...

Embodiment 1

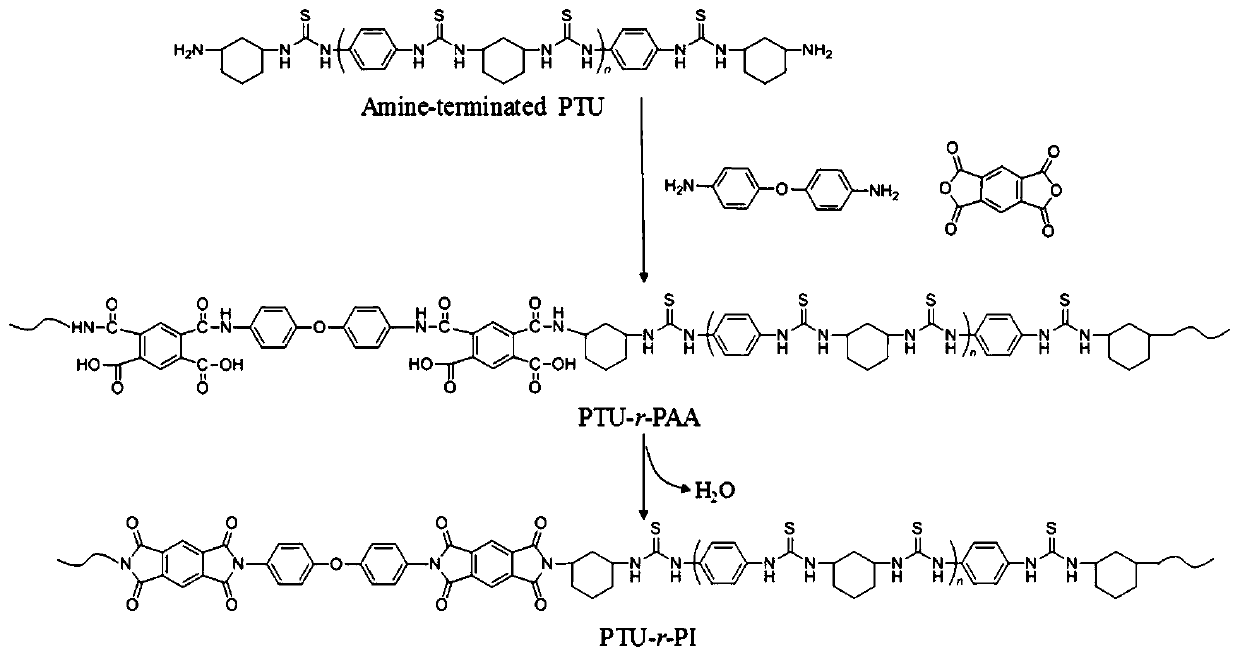

[0036] see figure 2 , a method for preparing an insulating medium for increasing energy storage density, comprising the following steps;

[0037] 1) Dissolve 0.96mmol 1,4-benzenediisothiocyanate completely in 2mL N,N-dimethylacetamide (DMAc), add 1mmol 1,3-cyclohexanediamine to the above solution, and The reaction was carried out under ambient and room temperature conditions for 6 hours to obtain an amino-terminated polythiourea precursor.

[0038] 2) Prepare the amino-terminated polythiourea precursor according to step 1), add 0.96mmol 4,4'-diaminodiphenyl ether and 1mmol pyromellitic dianhydride to the reaction solution in sequence, and make it under nitrogen environment and room temperature After reacting for 18 hours, a random copolymer (PTU-r-PAA) solution of polythiourea and polyamic acid was obtained.

[0039] 3) Spread the random copolymer PTU-r-PAA solution on a clean copper plate by casting method, and use a gradient temperature rise (70°C, 3 hours; 100°C, 1 hour;...

Embodiment 2

[0064] A method for preparing an insulating medium for increasing energy storage density, comprising the following steps;

[0065] 1) Dissolve 0.96mmol 1,4-benzenediisothiocyanate completely in 1mL N,N-dimethylacetamide (DMAc), add 1mmol 1,3-cyclohexanediamine to the above solution, and The reaction was carried out for 3 hours under ambient and room temperature conditions to obtain an amino-terminated polythiourea precursor.

[0066] 2) Prepare the amino-terminated polythiourea precursor according to step 1), add 0.96mmol 4,4'-diaminodiphenyl ether and 1mmol pyromellitic dianhydride to the reaction solution in sequence, and react under nitrogen environment and room temperature After 18 hours, a random copolymer (PTU-r-PAA) solution of polythiourea and polyamic acid was obtained.

[0067] 3) Spread the random copolymer PTU-r-PAA solution on a clean copper plate by casting method, and use a gradient temperature rise (70°C, 3 hours; 100°C, 1 hour; 120°C, 1 hour; 150°C , 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com