Biochemical treatment method for acrylic acid and ester production wastewater

A technology for biochemical treatment and production of wastewater, applied in the field of water treatment, can solve problems such as large fuel gas consumption, incinerator corrosion, and increased operating costs, and achieve the effects of improving biodegradability, catalytic performance, and large electrode surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

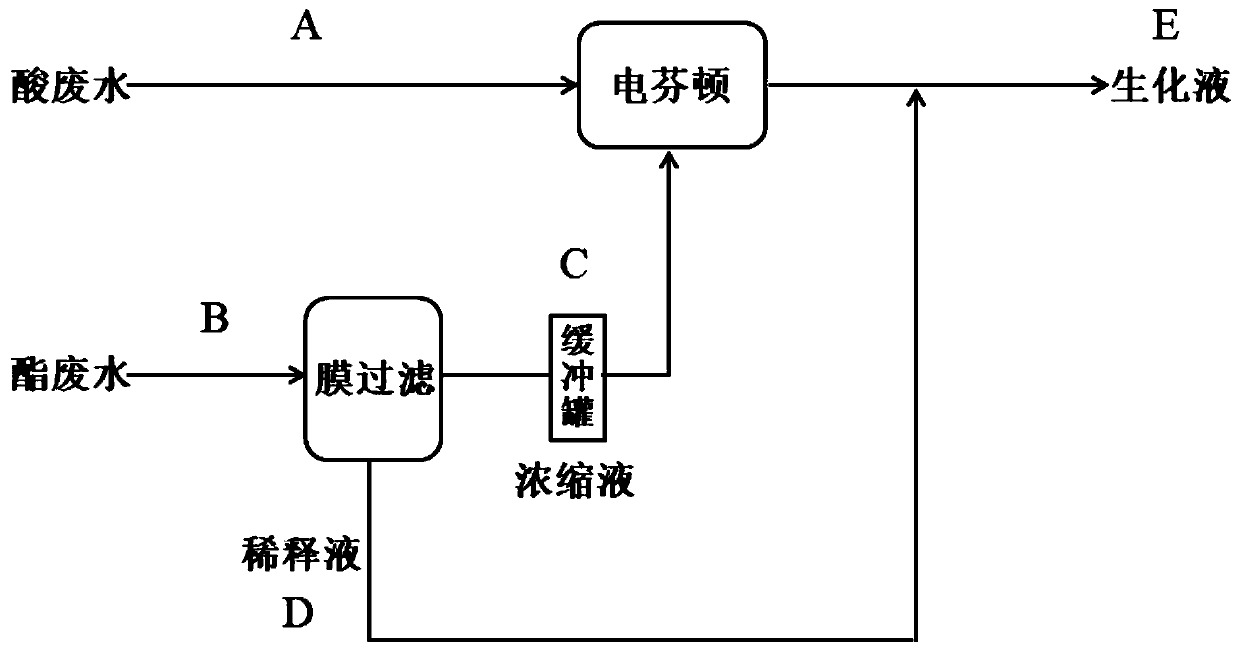

[0024] A biochemical treatment method for acrylic acid and ester production wastewater, the process flow diagram is as follows figure 1 As shown, the specific process is as follows:

[0025] (1) In the acrylic acid production process, the waste water containing acrylic acid obtained during the two-step oxidation of propylene, quenching absorption, purification and separation is recorded as acid waste water A;

[0026] (2) The water produced by the reaction of acrylic acid and butanol, the process water used to extract the catalyst, and the ester-containing wastewater produced by vacuum distillation are mixed and recorded as ester wastewater B. After the ester wastewater B is treated with a filtration and concentration device, concentrated wastewater C and Dilute waste water D after filtration;

[0027] (3) Concentrated waste water C and acid waste water A are mixed, and after electro-Fenton treatment and filtered diluted waste water D is mixed into waste water E to enter the ...

Embodiment 2

[0032] A kind of biochemical treatment method of acrylic acid and ester production waste water, concrete process is the same as embodiment 1, difference is:

[0033] The initial COD of acid wastewater A is 85000mg / L, and the pH value is 3.5;

[0034] The initial COD of ester wastewater B is 83000mg / L, and the pH value is 8.5. After membrane concentration, the COD of concentrated wastewater C is 250000mg / L, and the pH value is 8.7. The COD of diluted wastewater D after filtration is 4600mg / L, and the pH value is It is 4.5, concentrated wastewater C and acid wastewater A are mixed and passed through an electric Fenton voltage of 10V. During the treatment process, hydrogen peroxide with a concentration of 3.14 mmol / L is added for treatment with an electric Fenton device, and then mixed with filtered diluted wastewater D, COD It is 25000mg / L, the pH value is 6.1, and it enters the biochemical process for treatment.

Embodiment 3

[0036] A kind of biochemical treatment method of acrylic acid and ester production waste water, concrete process is the same as embodiment 1, difference is:

[0037] The initial COD of acid wastewater A is 92000mg / L, and the pH value is 4.2;

[0038] The initial COD of ester wastewater B is 85,000 mg / L, and the pH value is 9.0. After membrane concentration, the COD of concentrated wastewater C is 270,000 mg / L, and the pH value is 9.3. After filtration, the COD of diluted wastewater D is 5,100 mg / L, and the pH value is It is 5.2. After the concentrated wastewater C and the acid wastewater A are mixed, the voltage of the electro-Fenton is 10V. During the treatment, hydrogen peroxide with a concentration of 3.14 mmol / L is added to the electro-Fenton device for treatment, and then mixed with the diluted wastewater D after filtration, the COD It is 24000mg / L, the pH value is 5.8, and it enters the biochemical process for treatment.

[0039]The electric Fenton anode of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com