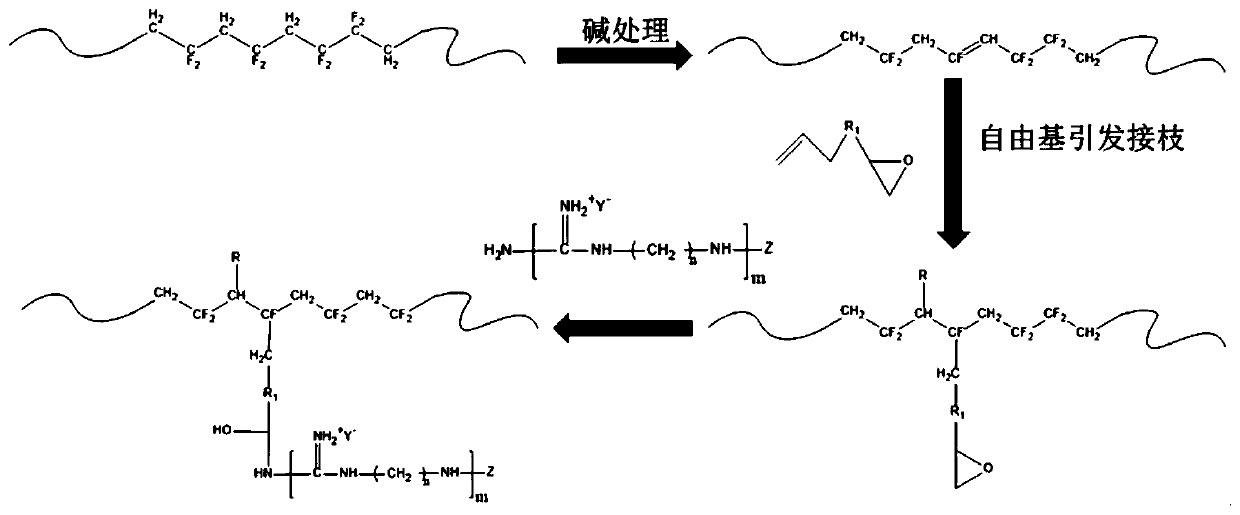

Guanidine salt antibacterial agent grafted modified polyvinylidene fluoride and preparation method thereof

A polyvinylidene fluoride, graft modification technology, applied in the manufacture of rayon, single-component halogenated hydrocarbon rayon, chemical characteristics of fibers, etc., can solve the problem of easy removal of antibacterial components and achieve long-lasting excellent The effect of broad-spectrum antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

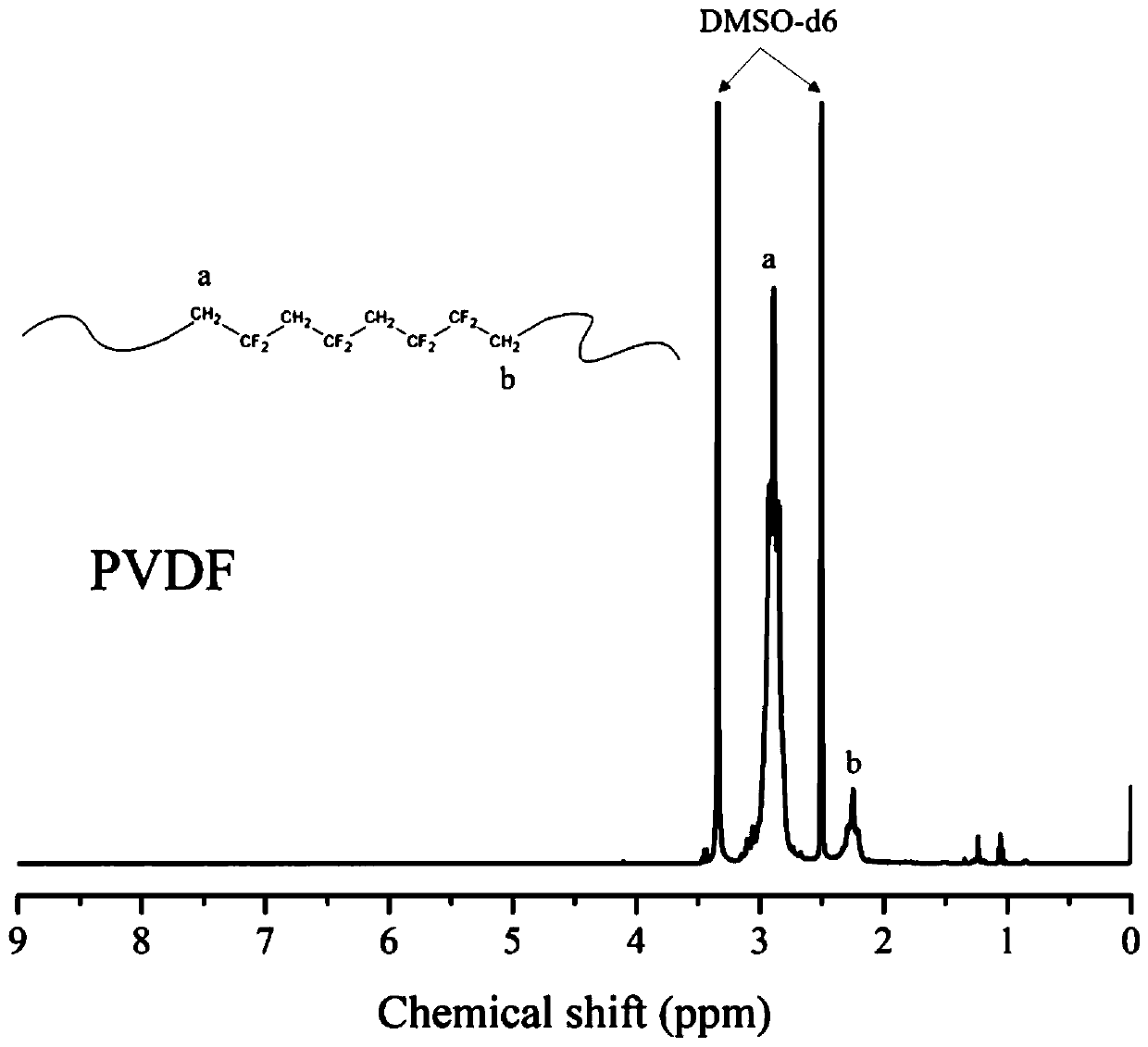

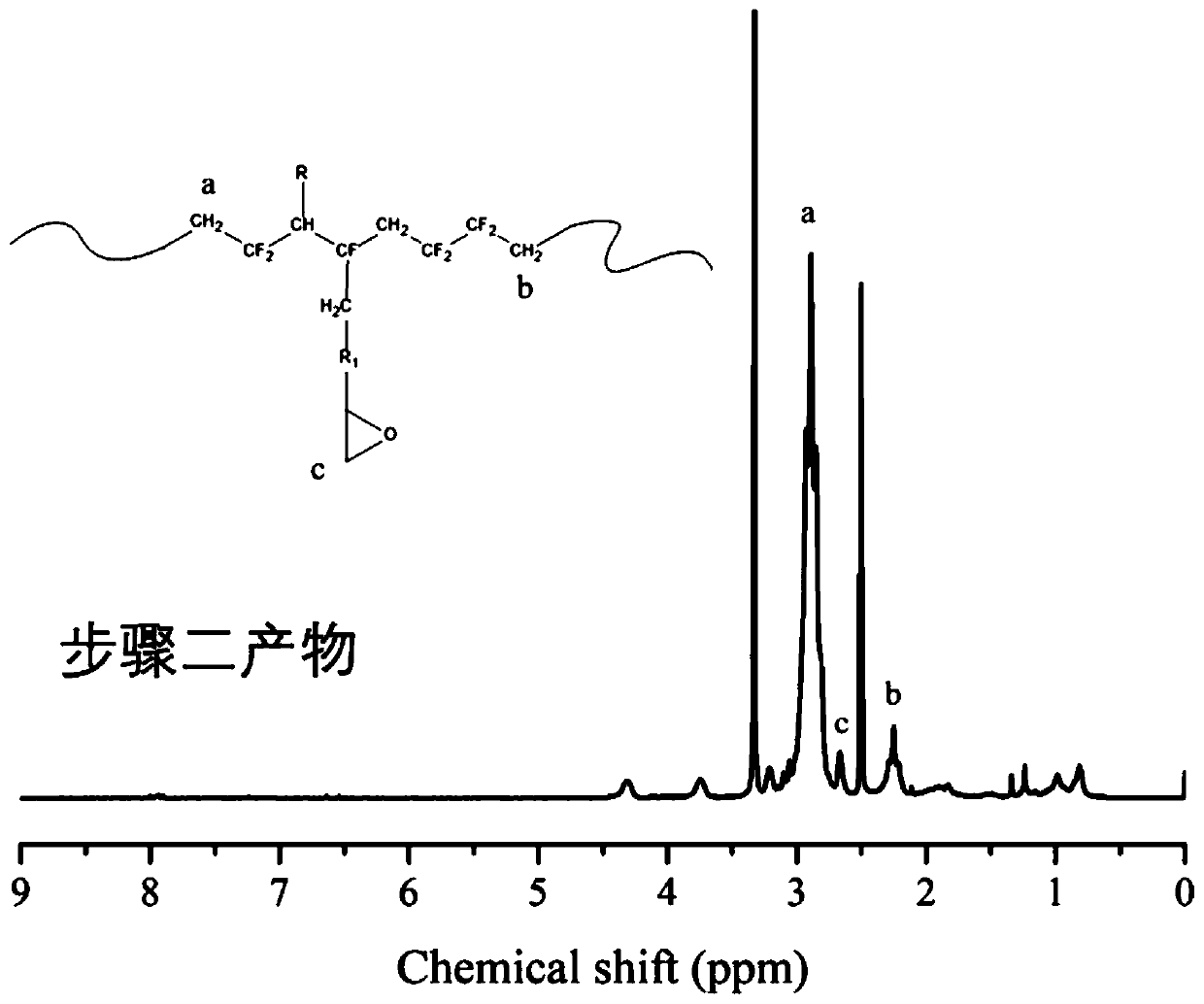

[0046] Immerse 20g of PVDF (molecular weight: 270,000) in a 1mol / L sodium hydroxide aqueous solution, stir at 60°C for 30 minutes, then filter with suction and wash with deionized water until neutral, and dry in a vacuum oven for 24 hours to obtain 19.5g of alkali Treated PVDF powder. Then take 10 grams of the above powder and dissolve in 90 grams of N,N-dimethylformamide, add 2.22 grams of glycidyl methacrylate and 1.89 grams of benzoyl peroxide, and react at 75° C. for 12 hours. Finally, 1 g of polyhexamethyleneguanidine hydrochloride was dissolved in 10 ml of ethanol and added to the reaction solution, and reacted at 50° C. for 18 hours, and the resulting solution was named P1.

Embodiment 2

[0048] Immerse 20g of PVDF (molecular weight: 270,000) in a 4mol / L aqueous solution of sodium orthosilicate, stir at 50°C for 40 minutes, filter with suction, wash with deionized water until neutral, and dry in a vacuum oven for 24 hours to obtain 19.5g PVDF powder after alkali treatment. Then take 15 grams of the above powder and dissolve in 85 grams of N,N-dimethylacetamide, add 1.79 grams of allyl glycidyl ether and 1.89 grams of benzoyl peroxide, and react at 80° C. for 8 hours. Finally, 1 g of polyhexamethylene guanidine phosphate was dissolved in 5 ml of methanol and added to the reaction solution, and reacted at 60° C. for 12 hours, and the resulting solution was named P2.

Embodiment 3

[0050] Immerse 20g of PVDF (molecular weight: 540,000) in an aqueous solution of 2mol / L potassium hydroxide, stir at 60°C for 20 minutes, filter with suction, wash with deionized water until neutral, and dry in a vacuum oven for 24 hours to obtain 19.5g of alkali Treated PVDF powder. Then take 10 grams of the above powder and dissolve in 90 grams of N-methylpyrrolidone, add 3.33 grams of glycidyl methacrylate and 2.13 grams of dicumyl peroxide, and react at 85° C. for 4 hours. Finally, 1.5 g of polyhexamethyleneguanidine nitrate was dissolved in 10 ml of dimethyl sulfoxide and added to the reaction solution, and reacted at 70° C. for 8 hours, and the resulting solution was named P3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com