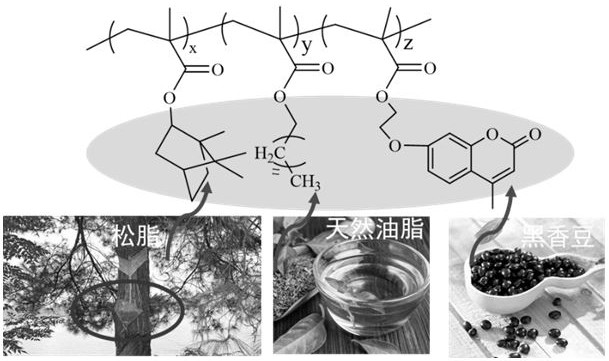

A kind of preparation method of bio-based acrylate anti-warping adhesive tape

A bio-based acrylate and acrylate technology, applied in adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as high toxicity, prone to warping, and high pollution in the curing process , to achieve the effects of excellent bonding performance, high curing efficiency, and excellent warpage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

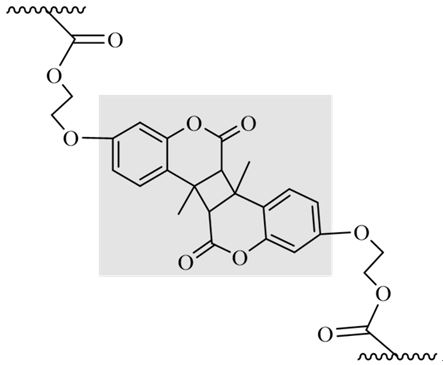

[0031] First, add 100 g of 7-hydroxycoumarin into a 1000 mL three-necked flask, then add 70 g of methanol, and put it in a low temperature tank to cool to -20 o C, stirring for 10 min. Add the mixed solution of 120 g of acryloyl chloride and 70 g of dichloromethane into the constant pressure funnel, and slowly add it dropwise (6-7 d / s). Organic solvents. Thermally dissolve 300 g of anhydrous ether and methanol in a mixed solvent with a mass ratio of 1:2, obtain the filtrate after suction filtration, recrystallize at -30~-20°C, filter with suction, and dry in vacuum at room temperature for 48 h to obtain acrylate Modified 7-hydroxycoumarin.

[0032] Bio-based isobornyl methacrylate (brand: SARBIO6105) 50 g, bio-based isobornyl acrylate (brand: SARBIO5102) 35 g, bio-based tridecyl methacrylate (brand: SARBIO6101) 410 g, Bio-based heptadecanyl methacrylate (brand: SARBIO6104) 105 g, acrylate-modified 7-hydroxycoumarin 50 g, benzoyl peroxide 3 g, azobisisobutyronitrile 1.5 g, t...

Embodiment 2

[0036] First, add 100 g of 7-hydroxycoumarin into a 1000 mL three-necked flask, then add 70 g of methanol, and place it in a low temperature tank to cool to -20 o C, stirring for 10 min. Add the mixed solution of 120 g of methacryloyl chloride and 70 g of dichloromethane into the constant pressure funnel, add it dropwise slowly (6-7 d / s), continue to react at 25°C for 2 h after the dropwise addition, and spin off under reduced pressure residual organic solvents. Thermally dissolve 300 g of anhydrous ether and methanol in a mixed solvent with a mass ratio of 1:3, obtain the filtrate after suction filtration, recrystallize at -30~-20°C, suction filtration, and vacuum-dry at room temperature for 48 h to obtain methyl Acrylate-modified 7-hydroxycoumarin.

[0037] Bio-based isobornyl methacrylate (brand: SARBIO6105) 65 g, bio-based isobornyl acrylate (brand: SARBIO5102) 20 g, bio-based tridecyl methacrylate (brand: SARBIO6101) 450 g, bio Heptadecyl methacrylate (brand: SARBIO610...

Embodiment 3

[0041] First, 90 g of 7-hydroxy-4-methylcoumarin was added to a 1000 mL three-necked flask, and then 60 g of methanol was added, and placed in a low temperature tank to cool to -20 o C, stirring for 10 min. Add the mixed solution of 110 g of acryloyl chloride and 80 g of dichloromethane into the constant pressure funnel, add it dropwise slowly (6-7 d / s), continue to react at 20°C for 2 h after the dropwise addition, and spin off the remaining Organic solvents. Thermally dissolve 300 g of anhydrous ether and methanol in a mixed solvent with a mass ratio of 1:2, obtain the filtrate after suction filtration, recrystallize at -30~-20°C, filter with suction, and dry in vacuum at room temperature for 48 h to obtain acrylate Modified 7-hydroxy-4-methylcoumarin.

[0042] Bio-based isobornyl methacrylate (brand: SARBIO6105) 115 g, bio-based isobornyl acrylate (brand: SARBIO5102) 70 g, bio-based tridecyl methacrylate (brand: Terra C13-MA) 350 g g. Bio-based heptadecyl methacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com