Preparation of an environmentally friendly silicon-based additive and its application in refractory materials

A technology of refractory materials and application methods, which is applied in the field of preparation of silicon-based additives for refractory material modification, can solve the problems of troublesome use by refractory material enterprises, large fluctuations in the quality of silicon powder, and low reactivity, etc., to achieve process environmental protection, The effect of low cost and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

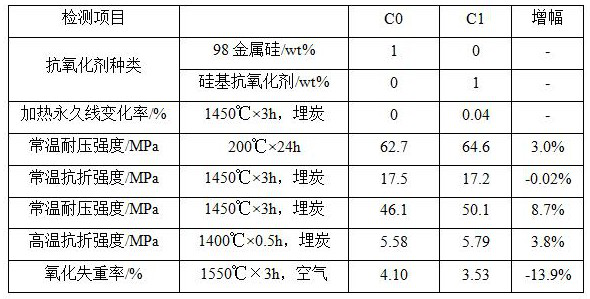

[0038]Domestic manufacturer A in its blast furnace out of iron ditch Al2O3The environmentally-friendly silicon-based additive and 98-stage metal silicon powder are used in detail as the effect of the antioxidant use, and the test results are shown in Table 1. The water injection of the environmentally-friendly silicon-based additive was carried out frequently (110 ° C × 24 h), and the medium temperature (1100 ° C × 3H) and high temperature (1450 ° C × 3H) were significantly improved, increased at 16.82 ~ 32.53. % Is not. Further, in the high temperature resistance and anti-oxidation resistance, 15.87% and 5.33% of the protocols are also 15.87% and 5.33% properties.

[0039]Table 1 Application Results of the Eating Silicon-Base Addition in Manufacturer A

[0040]

Embodiment 2

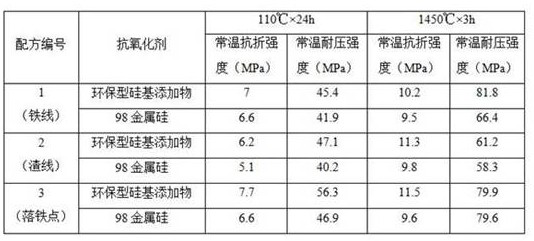

[0042]Domestic manufacturer B in its blast furnace out of iron ditch Al2O3The application of environmentally friendly silicon-based additives is made in the Tiegou Iron, the slag line and the falling iron site, respectively, with the 98-level metal silicon powder in the formulation, focusing on comparison. The strength data after the heat treatment after 110 ° C × 24 h and 1450 ° C × 3H, as shown in Table 2. It can be seen that the same conclusions are obtained in three formulations, and the intensity of the formulation of the environmentally friendly silicon-based additive is the normal temperature and high temperature treatment of high temperature treatment, and there is a significant increase in metal silicon powder according to the 98-stage metal silicon powder.

[0043]Table 2 Application Results of Embroofing Silicon-based Additions in Millennium Bases of Manufacturer B

[0044]

[0045]Note: The Trump is different from its different parts of service, so it is optimized in the formula ...

Embodiment 3

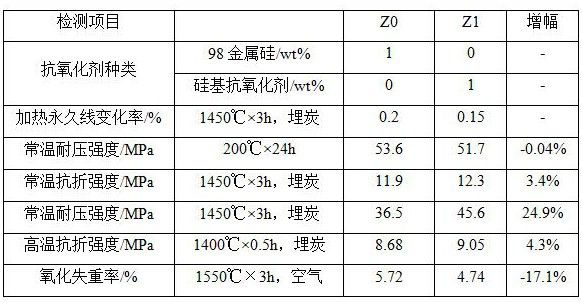

[0047]Domestic manufacturers h at its 260 tons of fish thunder slag wire2O3The application test of environmentally friendly silicon-based additives in the -sic-c brick, and the test results are shown in Table 3. It can be seen that the torpedo slag line AL as an environmentally friendly silicon-based additive is an antioxidant.2O3The intensity of the-SiC-C brick has improved, especially the normal temperature withstand voltage strength after high temperature buried charcoal, an increase of 24.9%. Further, in the thermal strength, it is at the same level and slightly 4.3% in the same level and slightly higher with a 98-stage metal silicon powder. In antioxidant, environmentally friendly silicon-based additives are also significantly better than 98-stage metal silica powder, and the two sets of samples are subjected to an environmentally friendly silicon-based product compared to the graphite oxidation rate of 1550 ° C × 3h air. The weight loss rate of the anti-oxidant slag brick solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com