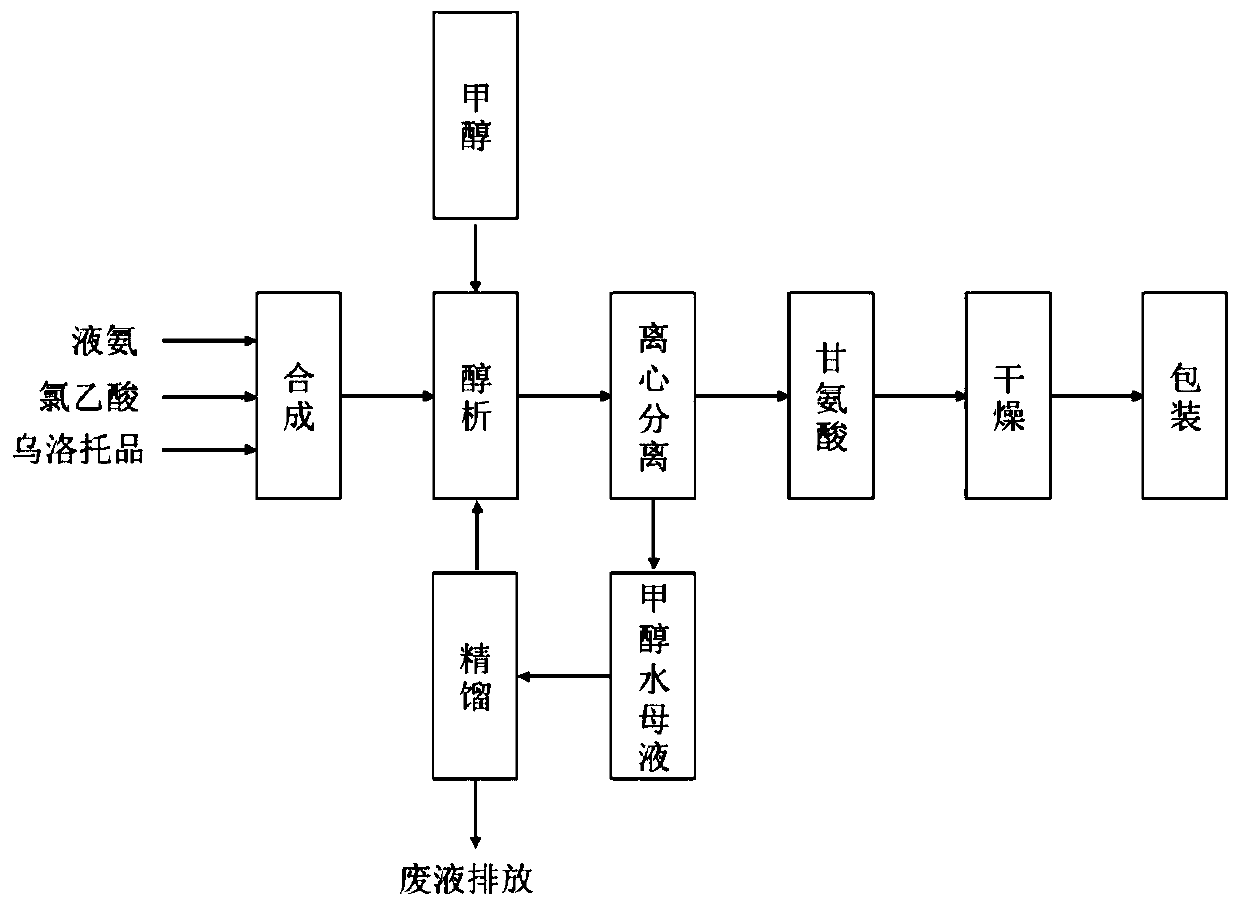

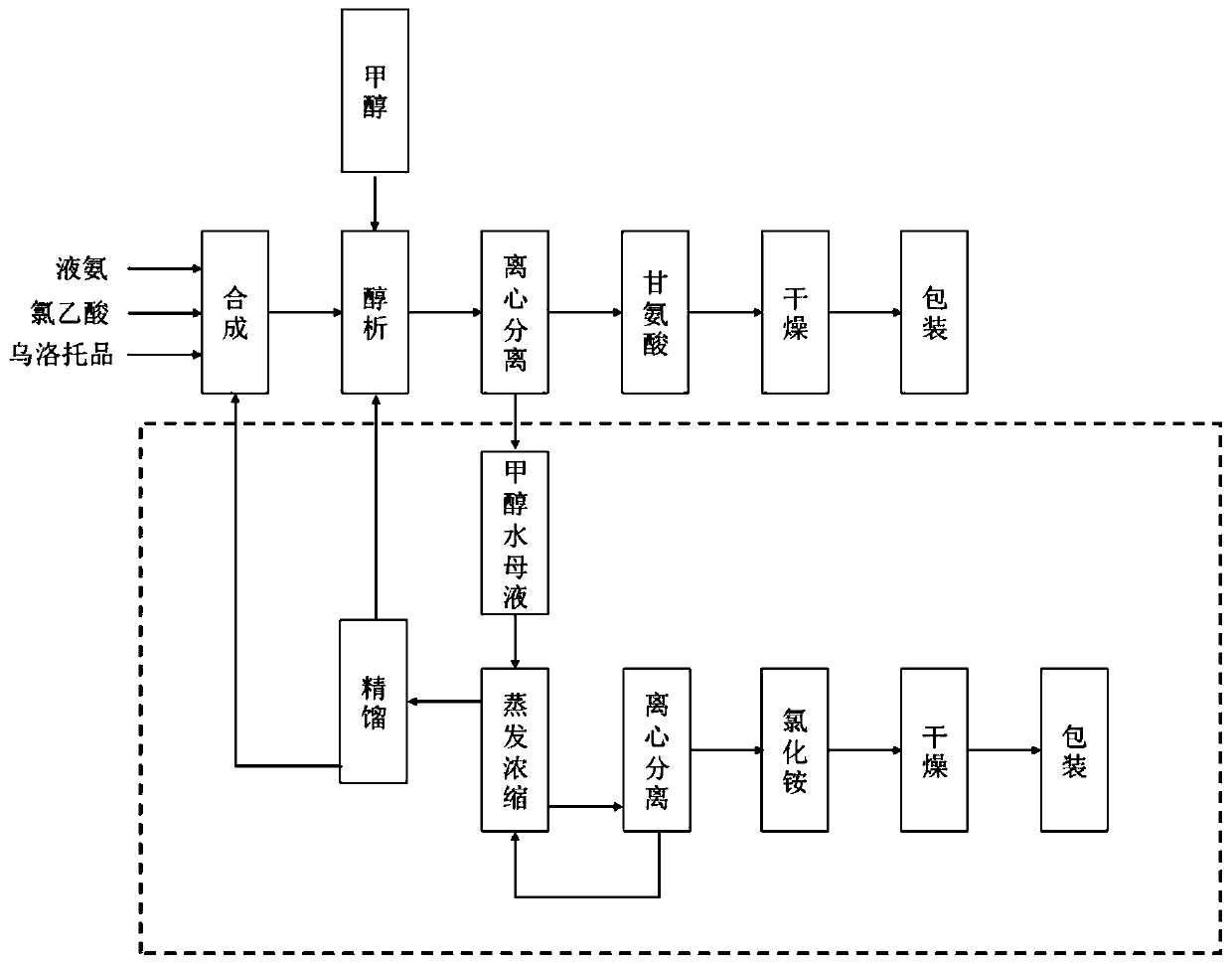

Processing method of glycine production wastewater

A technology for the production of wastewater and treatment methods, which is applied in natural water treatment, multi-stage water treatment, heating water/sewage treatment, etc. It can solve the problems of complex condensate composition and unstable glycine production process, and achieve reduction of reaction, COD and The effect of reducing the content of ammonia nitrogen and reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

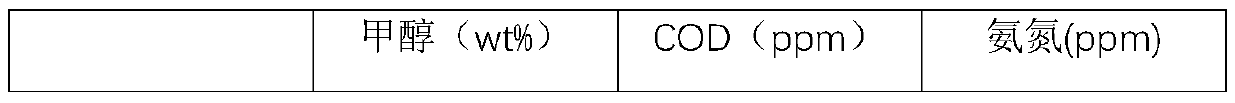

Embodiment 1

[0024] In a small test, the waste water after alcohol analysis and centrifugal separation of glycine in the production process of glycine by chloroacetic acid method was taken, and the mass content of each component was analyzed as methanol 66%, water 24%, ammonium chloride 7%, urotropine 1.2%, glycine and other organic impurities 1.8%. The waste water is evaporated and concentrated by a rotary evaporator to recover ammonium chloride. The pressure of the evaporation system is controlled at -0.09MPa and the evaporation temperature is 55°C. After analysis, the purity of ammonium chloride was 93%. The condensate is separated from methanol and water by a rectification device, and the temperature of the bottom of the tower is controlled not to be higher than 100°C, and the temperature of the top of the tower is 65°C. The composition of the tower top condensate and tower still mother liquor is analyzed as follows (wherein the COD content is the content after deducting methanol):

...

Embodiment 2

[0027] In the pilot test, the waste water after alcohol analysis and centrifugal separation of glycine in the production process of glycine by chloroacetic acid method was taken, and the mass content of each component was analyzed as methanol 60%, water 30%, ammonium chloride 7%, urotropine 1.4%, glycine and other organic impurities 1.6%. The waste water is evaporated and concentrated by the MVR evaporation system to recover ammonium chloride. The pressure of the evaporation system is controlled at -0.06MPa, the evaporation temperature is 75°C, and the recovery rate of ammonium chloride is 78%. After analysis, the purity of ammonium chloride was 90%. The condensate is separated from methanol and water by a rectification device, and the temperature of the bottom of the tower is controlled not to be higher than 100°C, and the temperature of the top of the tower is 65°C. The composition of the tower top condensate and tower still mother liquor is analyzed as follows (wherein the...

Embodiment 3

[0031] In the pilot test, the waste water after alcohol analysis and centrifugal separation of glycine in the production process of glycine by chloroacetic acid method was taken, and the mass content of each component was analyzed as methanol 60%, water 30%, ammonium chloride 7%, urotropine 1.4%, glycine and other organic impurities 1.6%. The wastewater is evaporated and concentrated by the double-effect evaporation system to recover ammonium chloride. The first-effect evaporation temperature of the evaporation system is controlled to be 80°C, the second-effect evaporation temperature is 60°C, and the recovery rate of ammonium chloride is 75%. After analysis, the purity of ammonium chloride was 89%. The first-effect and second-effect condensates enter the rectification tower together, and the methanol and water are separated through the rectification device. The temperature of the tower bottom is controlled not to be higher than 100°C, and the temperature of the tower top is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com