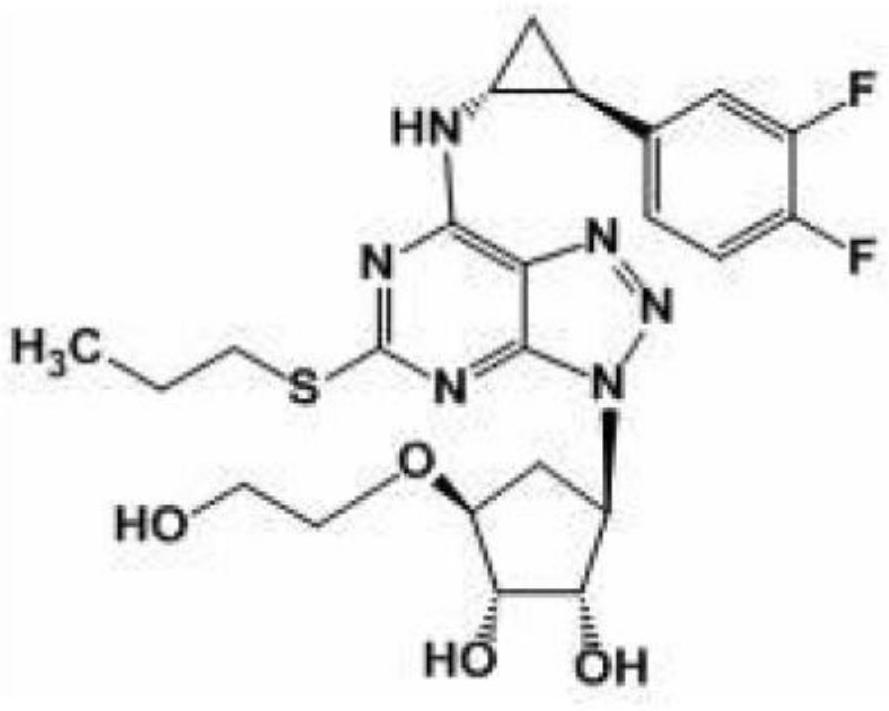

A kind of preparation method of ticagrelor key intermediate iodide

A technology of ticagrelor and an intermediate, which is applied in the field of pharmaceutical synthesis, can solve the problems of triphenylphosphine oxide by-product, sodium p-toluenesulfonate by-product, unfavorable industrial production, etc. Yield, the effect that is conducive to production cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

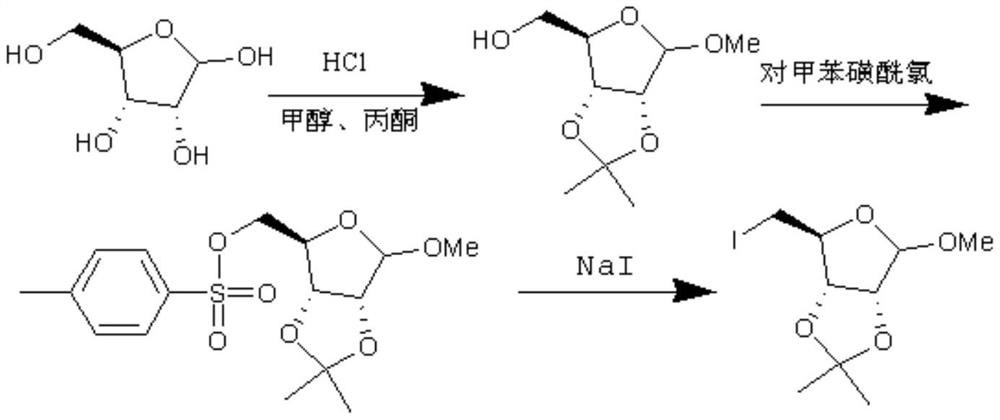

[0039] Synthesis of Intermediate 1

[0040] The specific synthesis steps are as follows: add 100ml of acetone, 100ml of methanol, and 20g of D-ribose (0.133mol) into a 250ml reaction flask, add 2g of thionyl chloride dropwise at a controlled temperature of 10-15°C, and heat up to 25±3°C for 24 hours after adding , the solvent was recovered under negative pressure until no liquid was produced, and 27 g of intermediate 1 was obtained with a yield of 99% and a purity of 90%.

[0041] The yield of intermediate 1 was 99% and the purity was 90%.

[0042] The reaction route is as follows:

[0043]

Embodiment 2

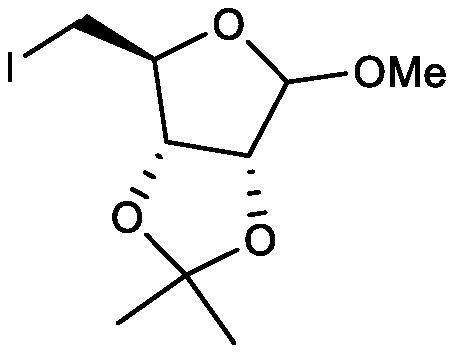

[0045] Synthesis of key intermediate iodides

[0046] The specific synthesis steps are as follows: add 27 g (0.132 mol) of the above-mentioned intermediate 1, 200 ml of acetonitrile, and 29.8 g (0.198 mol) of sodium iodide into a 500 ml reaction flask, nitrogen protection, and dropwise addition of trimethylchlorosilane at a temperature of 20±2°C 21.5g (0.198mol), kept for 1 hour after adding, add 20ml of water, recover the solvent under negative pressure until no liquid is left, add 100ml of water, extract three times with 100ml*3 of toluene, combine the organic layers, and concentrate under negative pressure until no liquid is produced, The key intermediate iodide 35.3g was obtained.

[0047] The yield of the key intermediate iodide was 85% and the purity was 95%.

[0048] The reaction route is as follows:

[0049]

[0050]To sum up, the preparation method of ticagrelor key intermediate iodide of the present invention adopts a two-step method to directly synthesize the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com