3D printing aramid airgel, its preparation method and application

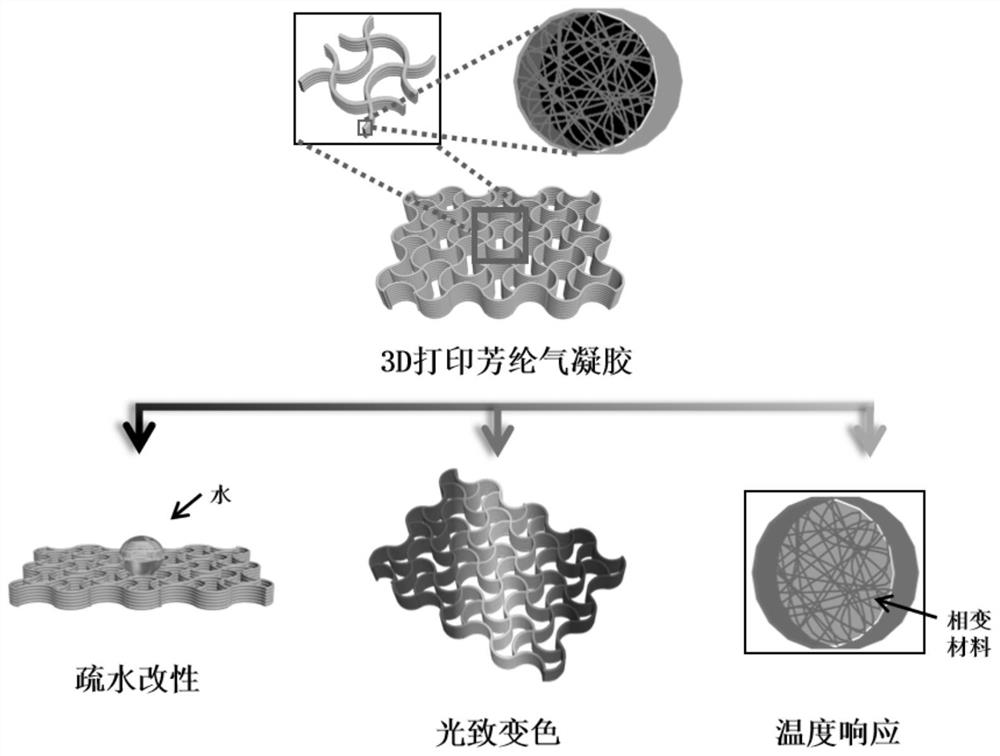

A 3D printing and airgel technology, applied in the field of 3D printing and nanoporous materials, can solve the problems of limited application of 3D graphene airgel, limited material performance and application, poor electrical conductivity and mechanical properties, etc., and achieve excellent mechanical properties Effects of performance and structure designability, broad dispersion, and fast low-temperature response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] An aspect of the embodiments of the present invention provides a method for preparing a 3D printing aramid aerogel, comprising:

[0046] Solvent replacement is performed on the 3D printed aramid fiber cryogel to obtain a 3D printed aramid fiber hydrogel;

[0047] The 3D printed aramid fiber hydrogel is dried to obtain a 3D printed aramid fiber aerogel.

[0048] In some preferred embodiments, the 3D printing ink further includes auxiliary components.

[0049] Further, the aramid nanofibers have a diameter of 1 nm to 1 μm and a length of 10 nm to 900 μm.

[0050] Further, the solvent includes, but is not limited to, dimethyl sulfoxide.

[0052] In some preferred embodiments, the concentration of the aramid nanofiber dispersion is 0.001 to 20wt%, preferably

[0056] Further, the 3D printing ink is printed at low temperature, and the printing temperature is -70~20 ℃, preferably -50

[0059] Specifically, the preparation method comprises: using a displacement solvent for the 3D p...

Embodiment 1

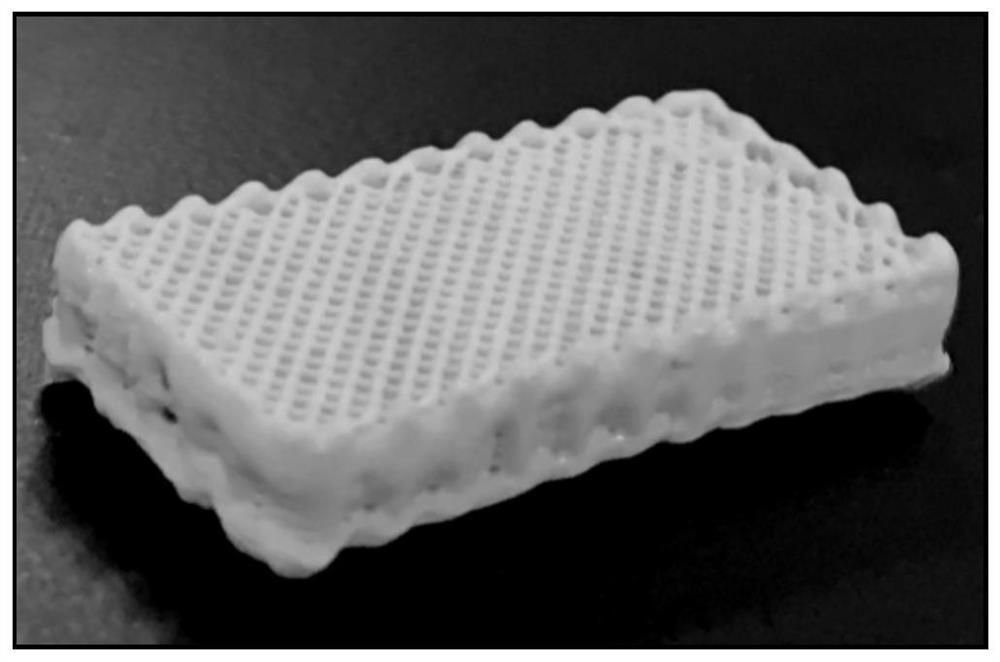

[0109] (2) The 3D printed aramid fiber cryogel was replaced by deionized water at 25°C to obtain the 3D printed aramid fiber hydrogel.

[0110] (3) The 3D printed aramid fiber hydrogel was freeze-dried at -100°C for 72 h to obtain the 3D printed aramid fiber aerogel.

[0113] FIG. 2 shows an optical photograph of the hydrophobically modified 3D printed aramid aerogel obtained in this example.

Embodiment 2

[0116] (2) The 3D printed aramid fiber hydrogel is obtained by replacing the 3D printed aramid fiber cryogel with absolute ethanol at -50°C.

[0117] (3) The 3D printed aramid hydrogel was dried by supercritical carbon dioxide for 24 h to obtain the 3D printed aramid aerogel.

[0120] FIG. 3 shows an optical photograph of the hydrophobically modified 3D printed aramid aerogel obtained in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com