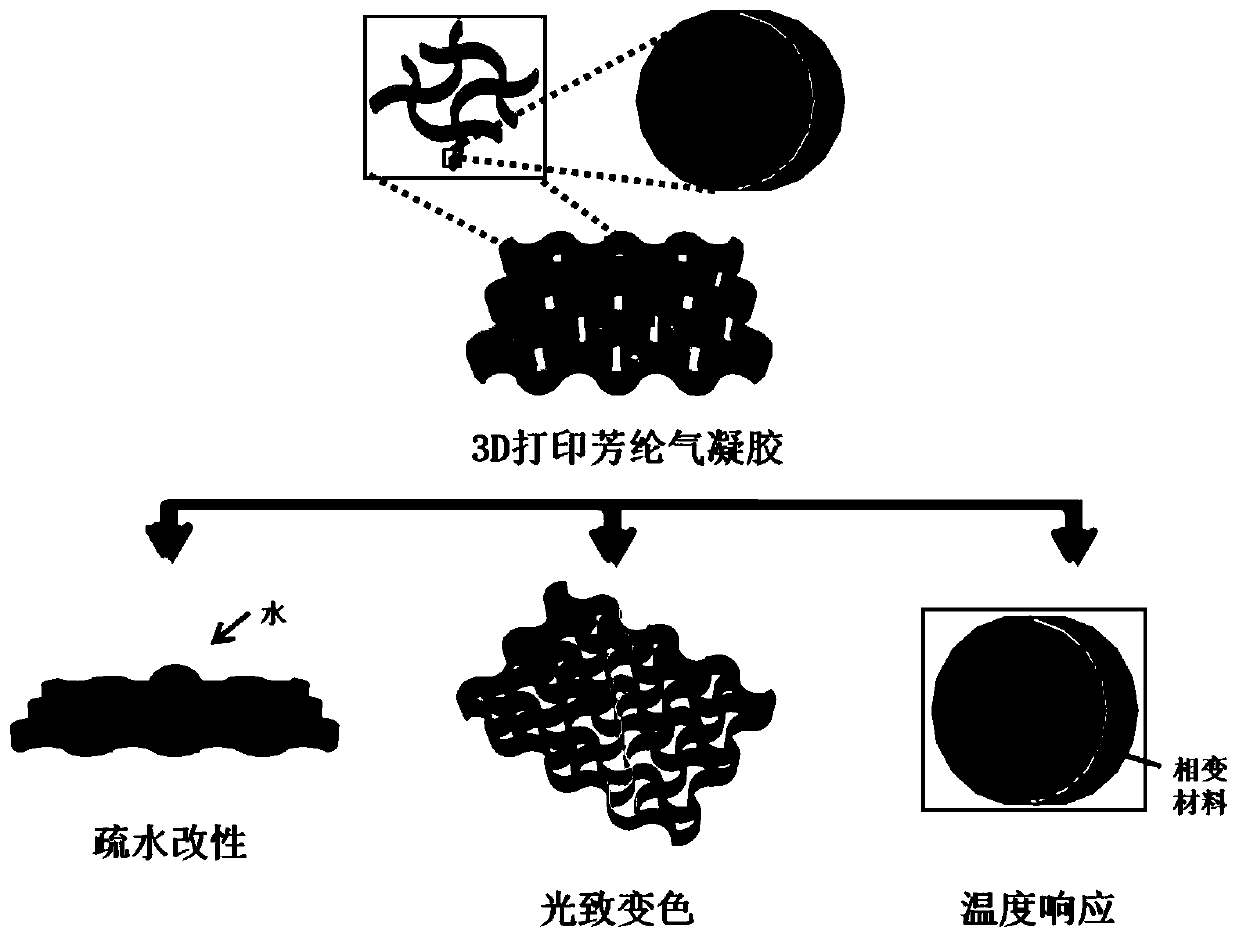

3D printing aramid aerogel, and preparation method and application thereof

A 3D printing and aerogel technology, applied in the field of 3D printing and nanoporous materials, can solve the problems of limited application of 3D graphene aerogel, limited material properties and applications, poor electrical conductivity and mechanical properties, etc., and achieve excellent mechanical properties. Effects of performance and structural designability, wide dispersion, fast low temperature response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] One aspect of the embodiments of the present invention provides a method for preparing 3D printing aramid airgel, which includes:

[0044] At least uniformly mixing aramid nanofibers and a solvent to form an aramid nanofiber dispersion;

[0045] 3D printing with the aramid nanofiber dispersion liquid as a 3D printing ink by freezing-direct writing forming method to obtain 3D printing aramid cryogel;

[0046] Performing solvent replacement on the 3D printed aramid cryogel to obtain a 3D printed aramid hydrogel;

[0047] The 3D printed aramid hydrogel is dried to obtain the 3D printed aramid airgel.

[0048] In some preferred embodiments, the 3D printing ink further includes auxiliary components.

[0049] Further, the diameter of the aramid nanofiber is 1 nm-1 μm, and the length is 10 nm-900 μm.

[0050] Further, the solvent includes dimethyl sulfoxide, but is not limited thereto.

[0051] Further, the main component of the 3D printing ink is aramid nanofiber / dimethyl...

Embodiment 1

[0108] (1) Put 10wt% aramid nanofiber / dimethyl sulfoxide / water mixed dispersion in the 3D printer storage bin at room temperature, design the structure by computer and import related programs, using a needle with an inner diameter of 410 μm, in- A 3D printed aramid cryogel with pyre structure was printed at 50°C.

[0109] (2) The 3D printed aramid cryogel was replaced by deionized water at 25°C to obtain a 3D printed aramid hydrogel.

[0110] (3) The 3D printed aramid hydrogel was freeze-dried at -100°C for 72 hours to obtain the 3D printed aramid airgel.

[0111] (4) The porosity of the 3D printed aramid airgel is 95%, and the specific surface area is 1800m 2 / g, the pore volume is 9cm 3 / g.

[0112] (5) The 3D printed aramid airgel was directly immersed in a 0.01wt% fluorocarbon resin solution for 10 seconds, and vacuum-dried at 30°C for 72 hours to obtain a hydrophobic 3D printed aramid airgel material.

[0113] figure 2 Optical photographs of the hydrophobically modi...

Embodiment 2

[0115] (1) Place 8wt% aramid nanofiber / dimethyl sulfoxide / ethanol dispersion in the 3D printer storage bin at room temperature, design the structure by computer and import related programs, using a needle with an inner diameter of 510 μm, at -50 3D printed aramid cryogel with pyre structure was printed at ℃.

[0116] (2) The 3D printed aramid cryogel was replaced with absolute ethanol at -50°C to obtain the 3D printed aramid hydrogel.

[0117] (3) Dry the 3D printed aramid hydrogel by supercritical carbon dioxide for 24 hours to obtain the 3D printed aramid airgel.

[0118] (4) The porosity of the 3D printed aramid airgel is 96%, and the specific surface area is 1900m 2 / g, the pore volume is 9cm 3 / g.

[0119] (5) The 3D printed aramid airgel was directly immersed in a 20wt% fluorocarbon resin solution for 5 seconds, and left to air at room temperature for 72 hours to obtain a hydrophobic 3D printed aramid airgel material.

[0120] image 3 Optical photographs of the hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com