A kind of negative electrode slurry of nickel-metal hydride battery and preparation method thereof

A technology for negative electrode slurry and nickel-metal hydride battery, which is applied to battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of long stirring ultrasonic time, poor stability of the slurry, and complicated use process, so as to eliminate the danger of fire. , good temperature consistency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Example 1 A negative electrode slurry for a nickel-hydrogen battery and its preparation method

[0044] This embodiment is a method for preparing the negative electrode slurry of a nickel-metal hydride battery, which is carried out in sequence according to the following steps:

[0045] (11) Dissolve 0.1kg of CMC powder in 30kg of deionized water to form a CMC aqueous solution, stir the CMC aqueous solution in a mixing tank at 100rpm for 3 hours, and vacuum for 5 minutes to obtain A1. The viscosity of A1 is 158cp;

[0046] (12) Slowly add 0.2kg of yttrium oxide (the particle size of yttrium oxide is 30-50nm) and 0.4kg of carbon black (the particle size of carbon black is 10-50nm) to A1 in four batches, and stir at 300rpm 2h, get B1;

[0047] (13) Pulverize 67.8 kg of hydrogen storage alloy to form hydrogen storage alloy powder (pass through a 200-mesh sieve), add hydrogen storage alloy powder to B1, and stir at 400 rpm for 1 hour to obtain C1;

[0048] (14) Add 5kg of t...

Embodiment 2-5

[0050] Example 2-5 Ni-MH battery negative electrode slurry and preparation method thereof

[0051] Examples 2-5 are respectively a nickel-hydrogen battery negative electrode slurry and its preparation method. The preparation steps are similar to those of Example 1, except that the corresponding technical parameters in the preparation process are different. See the table below for details.

[0052]

[0053] The nickel metal hydride battery negative electrode slurry prepared in this example 2-5 is coated on the negative electrode plate, which is easy to be evenly coated, easy to hang slurry, dried at 150°C for 5 minutes, and the plate made after rolling has good uniformity , no fracture and no deformation, after the coated pole plate is made into a nickel metal hydride battery, charge 100% with 1C, and discharge to 0.8V at 30C for electrochemical testing. The battery capacity of Examples 2-5 is 4.9-5.3Ah, large Current discharge for 20s, voltage ≥ 0.9V; high temperature 55 de...

Embodiment 6

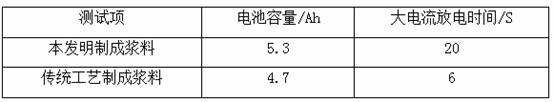

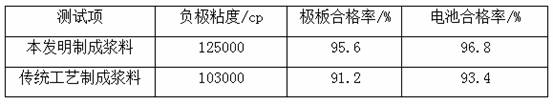

[0054] Example 6 Comparative Study on Performance of Ni-MH Battery Negative Electrode Slurry

[0055] In the process of preparing the negative electrode slurry of nickel-metal hydride batteries, the traditional process is to add all the negative electrode slurry raw materials into the mixing tank and stir for more than 10 hours. The mixing time is long, which affects the production capacity of the entire production line, and carbon black is not easy to mix and float On the surface of the pole plate; although in order to increase the viscosity of the slurry, the water content is reduced to achieve the purpose of increasing the viscosity of the slurry to achieve the dispersion of carbon black, but the dispersion effect is poor, and the water content is too low, the fluidity of the slurry will be very low Difference.

[0056] In this example, the performance of the negative electrode slurry prepared by dry mixing in the traditional process is compared with the negative electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com