Halide solid electrolyte, preparation method thereof and lithium ion battery

A solid electrolyte and halide technology, applied in the field of battery electrolytes, can solve the problems of long synthesis cycle of halide solid electrolyte, cumbersome preparation process, long sintering time, etc., and achieve the advantages of short sintering time, simple preparation process and reduction of lithium loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The first aspect of the embodiments of the present invention provides a method for preparing a halide solid electrolyte, comprising the following steps: ball milling lithium halide and non-metal halide to obtain a mixture; and performing spark plasma sintering or electric field assisted sintering on the mixture. Specifically: Weigh lithium halides and non-metal halides respectively, and put the weighed lithium halides and non-metal halides into a ball mill tank for ball milling to obtain a mixture; put the mixture into a mold, and place the mold in a discharge plasma The halide solid electrolyte can be obtained by sintering in a sintering system of sintering or electric field assisted sintering.

[0023] In the preparation method of the above-mentioned halide solid electrolyte, before the sintering step, it can be obtained only by ball milling once, and the preparation process is simple. Compared with the traditional preparation method, the synthesis efficiency is greatl...

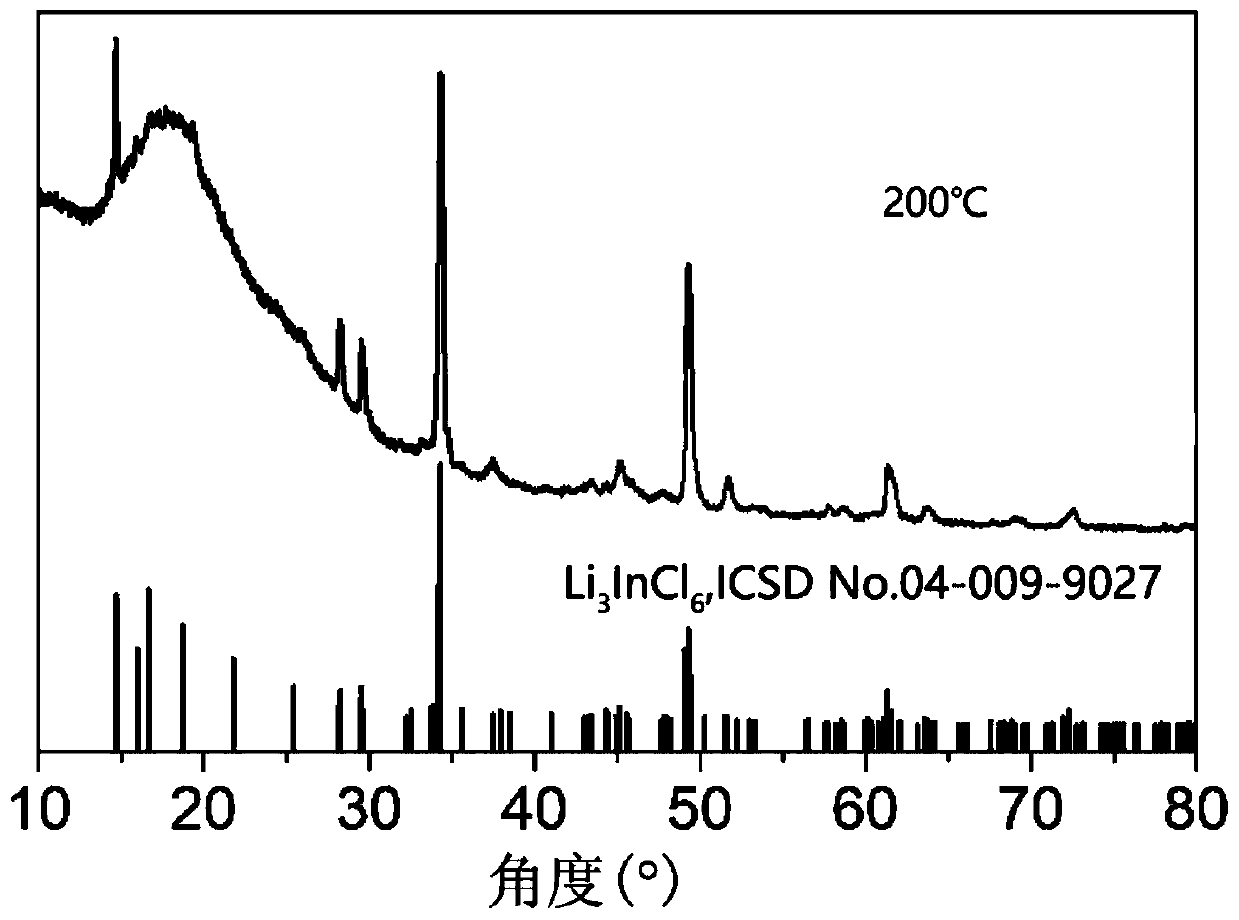

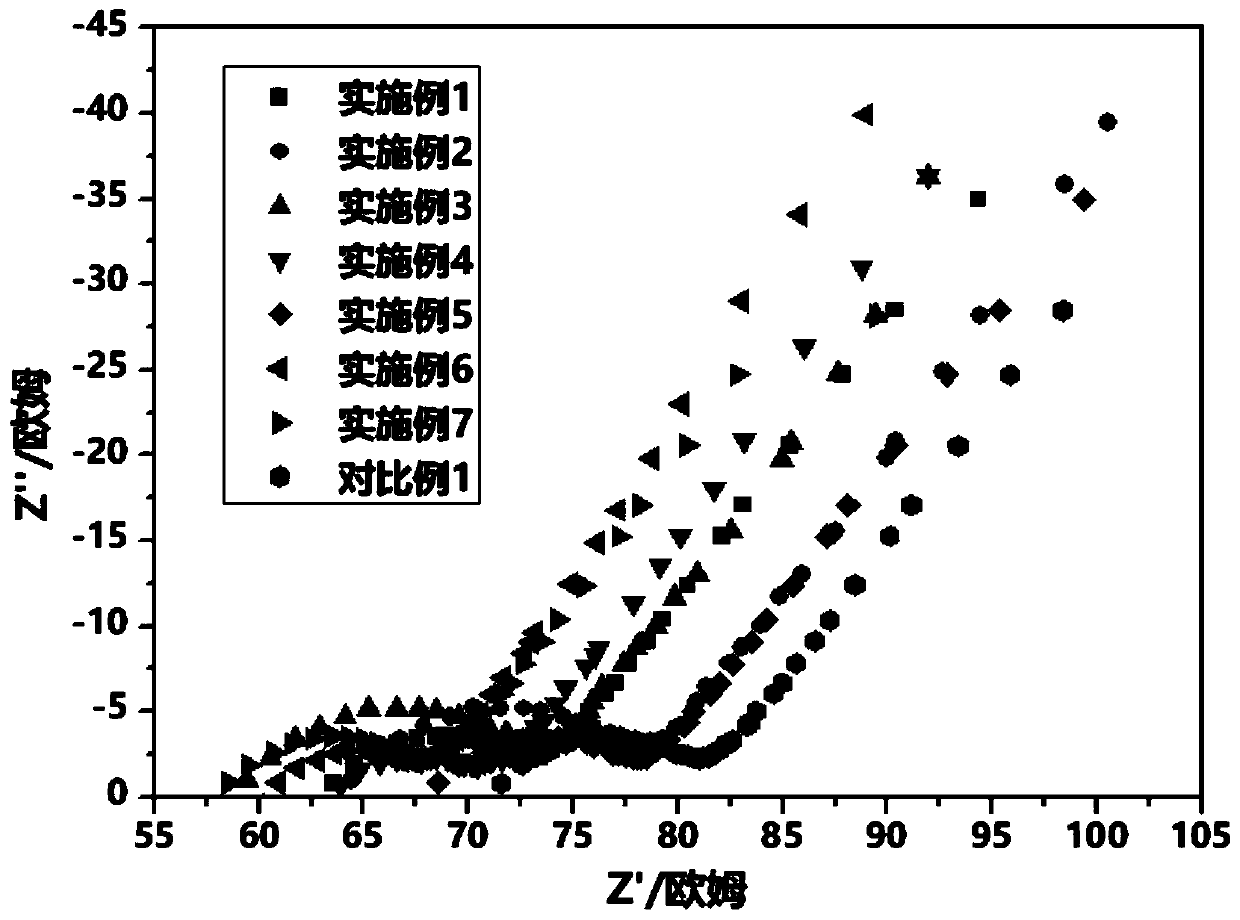

Embodiment 1

[0033] Weigh 12g lithium chloride (LiCl) and 4g indium chloride (InCl 3 ), put the above-mentioned powder into a ball mill jar equipped with zirconia balls, use isopropanol as a mixing agent, and the mass ratio of isopropanol to powder is 5:1. The rotational speed of the ball mill was adjusted to 350r / min, and the ball milling time was 60h. After the ball milling, the powder was put into a vacuum drying oven with a drying temperature of 80°C, and the drying time was 8h. Take out 12g of dried powder and pour it into a sintering mold, and then place the sintering mold in a sintering container. Surface activation is first performed on the above mixture powder material particles to enhance the reactivity of the mixture, wherein the activation voltage is 5V, the current is 3A, and the activation time is 30s. Then, under the protection of argon atmosphere, plasma activated rapid sintering was carried out, and the temperature was raised from room temperature to 250 °C at a rate of 1...

Embodiment 2

[0037] Weigh 12g lithium bromide (LiBr) and 4g yttrium bromide (YBr 3 ), put the above-mentioned powder into a ball mill tank equipped with zirconia balls, use isopropanol as a mixing agent, and the mass ratio of isopropanol to powder is 6:1, and the rotating speed of the ball mill is adjusted to 400r / min, and the ball milling time is 55 hours. After the ball milling, put the powder into a vacuum drying oven with a drying temperature of 60°C, and the drying time is 6 hours. Take out 2g of dried powder and pour it into a sintering mold, and then place the sintering mold in a sintering container. Surface activation is first performed on the above mixture powder material particles to enhance the reactivity of the mixture, wherein the activation voltage is 10V, the current is 5A, and the activation time is 60s. Then, under the protection of argon atmosphere, plasma activated rapid sintering was carried out, and the temperature was raised from room temperature to 150 °C at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Li-ion conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com