Polycarbonate cross-linked solid polymer electrolyte and application thereof

A technology of solid polymer and polycarbonate, which is applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., and can solve the problems of not being able to effectively deal with the volume strain of positive and negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] (1) Preparation of positive electrode sheet

[0063] A. Dissolve polyvinylidene fluoride (PVDF) in N-methylpyrrolidone at a concentration of 0.1 mol / L.

[0064] B. After mixing PVDF, positive electrode active material, and conductive carbon black at a mass ratio of 10:80:10, grind for at least 1 hour.

[0065] C. Scrape the slurry obtained in the previous step evenly on the aluminum foil with a thickness of 100-120 μm, first dry it in a 60°C oven, then dry it in a 120°C vacuum oven, roll it, and weigh it. Dry in a vacuum oven at 120°C and store in a glove box for later use.

[0066] (2) Preparation of negative electrode sheet

[0067] A. Dissolve PVDF in N-methylpyrrolidone at a concentration of 0.1mol / L.

[0068] B. After mixing PVDF, negative electrode active material, and conductive carbon black at a mass ratio of 10:80:10, grind for at least 1 hour.

[0069] C. Scrape the slurry obtained in the previous step evenly on the copper foil with a thickness of 100-120 ...

Embodiment 1

[0076] In the glove box, under an inert atmosphere, configure the polymer matrix according to the records in Table 1 (polymerization monomer is P1 (n=2)), a mixed solution of lithium salt and azobisisobutyronitrile (azobisisobutyronitrile accounts for 0.5% of the total mass of the target polymer matrix), inject it into the coin cell assembled according to the above-mentioned description; seal After polymerizing in an oven at 60°C for 12 hours, a solid polymer electrolyte is formed in an all-solid lithium battery.

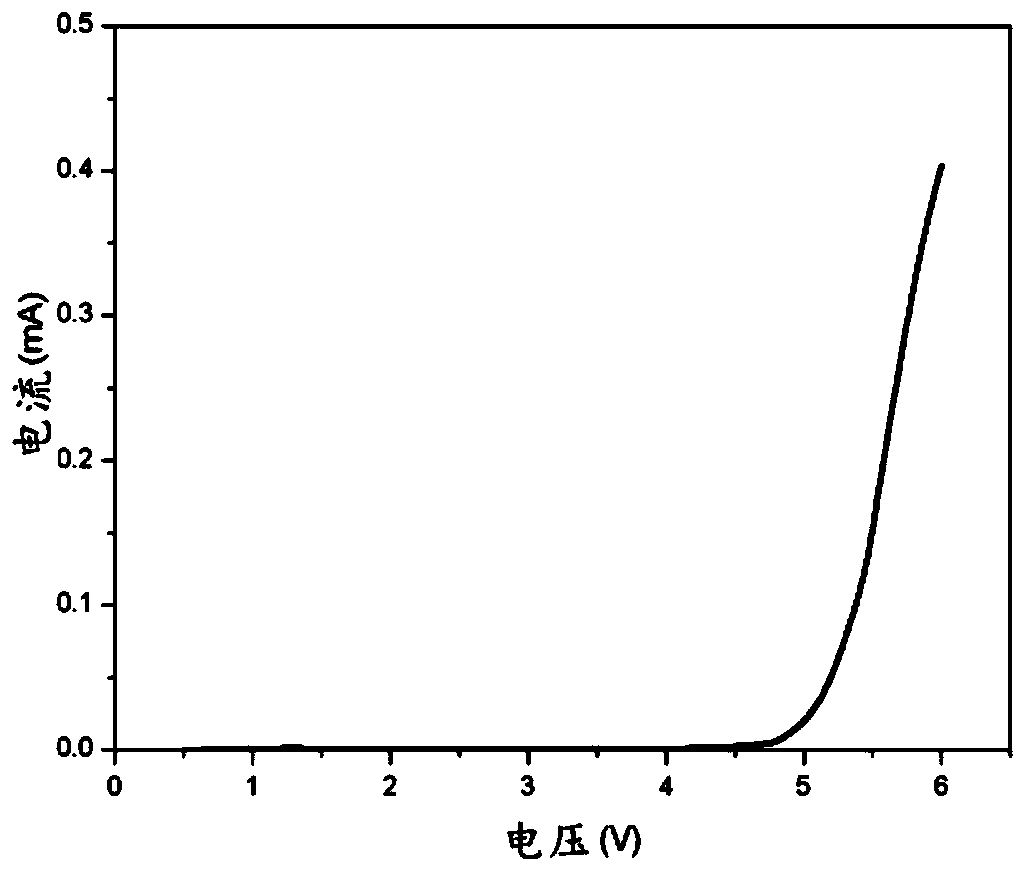

[0077] Electrochemical stability and tensile strength test (see figure 1 and Table 1).

[0078] Table 1 Solid polymer electrolyte composition and test results

[0079]

[0080] Depend on figure 1 It can be seen that the polymer electrolyte has an electrochemical window of 0-4.7V. It can be seen from Table 1 that the tensile strength of the polymer electrolyte membrane can reach 21MPa. The higher oxidation resistance and higher mechanical properties of the ele...

Embodiment 2

[0082] In the glove box, under an inert atmosphere, configure the polymer matrix according to the records in Table 2 (polymerization monomer is P2

[0083] (n=100)

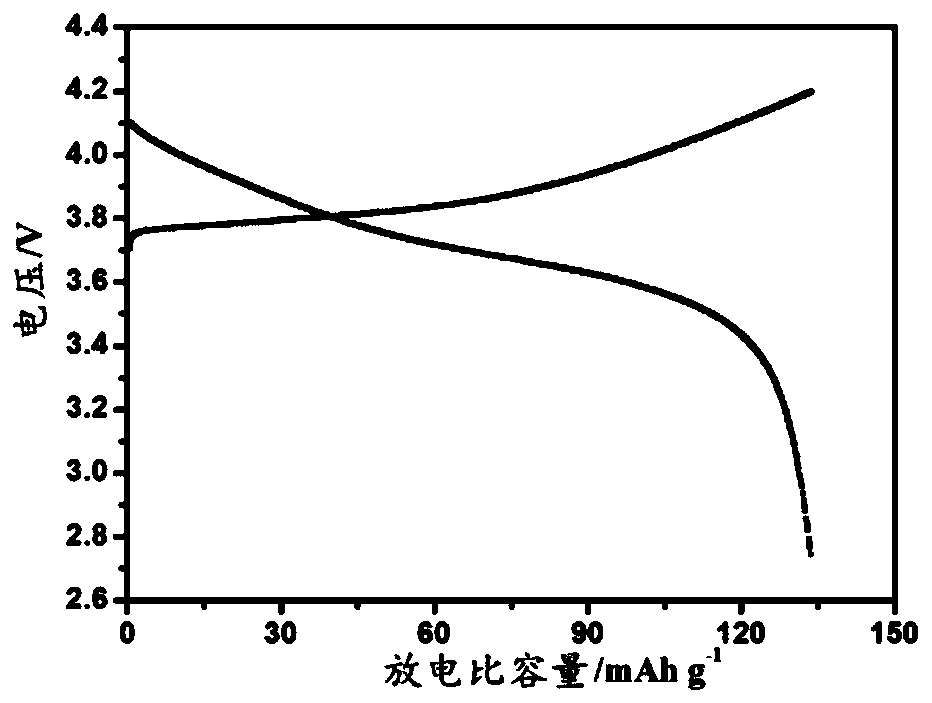

[0084] and polyethylene glycol diacrylate (this is obtained by crosslinking other monomers through polycarbonate, and the amount of the two accounts for 10% and 90% of the mass of the polymer matrix respectively), lithium salts and benzophenone-containing (polymerized 1% of the mass of the polymer matrix) in N,N-dimethylformamide solution, and the polymer matrix accounts for about 40% of the mass fraction of the solution. The solution was thoroughly stirred to obtain a clear and transparent viscous liquid. The above solution was evenly scraped on the polyimide non-woven membrane, then irradiated under a high-pressure mercury lamp (1000W) for 10min, and then dried to prepare a solid-state electrolyte membrane. The electrolyte membrane was dried in a vacuum oven at 70°C for 20 hours after being sliced, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com