Iron-zirconium-aluminum combined pillared bentonite composite material and preparation method thereof

A technology of composite materials and bentonite, applied in the field of materials, can solve the problems of reduced adsorption capacity, waste of adsorbents or raw materials, and complex processes, etc., and achieve the goals of increased specific surface area and porosity, strong cation replacement capacity, and enhanced physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation of Al pillar liquid: drop 80mL 0.4mol / L NaOH into AlCl at a rate of 5mL / min 3 In the solution, heat and stir in a constant temperature (60° C.) water bath for 3 to 4 hours. The obtained pillaring solution was placed at room temperature for 24 hours to facilitate aging.

[0040] Preparation of Fe, Al, Zr pillared bentonite: Weigh a certain amount of bentonite into a three-necked flask, add FeCl 3 solution and ZrOCl solution (FeCl 3 The ratio of ZrOCl and ZrOCl can be added arbitrarily, when the molar ratio of the two is 3:1, the effect is the best), and the bentonite is evenly dispersed in the FeCl 3 and ZrOCl solution, and finally drop a certain amount of Al pillar solution into a three-necked flask, and heat and stir in a water bath (60° C.) for 4 hours. Place at room temperature for 24h.

[0041] Washing of the sample: put the prepared sample in a centrifuge, centrifuge at 6000r / min for 5min, pour off the supernatant, add distilled water and repeat was...

experiment example

[0045] Test method for adsorption properties of products

[0046] Weigh a certain amount of adsorbent sample into a 250mL Erlenmeyer flask, add a certain concentration of crystal violet solution, adjust the temperature of the constant temperature oscillator, and shake it at a speed of 175rpm for a certain period of time. After the reaction is over, put the adsorbed solution to stand , Take an appropriate amount of supernatant and dilute it by a certain number of times to measure its absorbance with a UV spectrophotometer, and calculate the corresponding removal rate and adsorption amount.

[0047] Removal rate (η) is calculated according to the following formula:

[0048]

[0049] Wherein: η——the removal rate of Cu (II), %;

[0050] C 0 - the initial concentration of the solution, mg / L;

[0051] C t —concentration of the solution at time t, mg / L;

[0052] Adsorption capacity (q t ) is calculated according to the following formula:

[0053]

[0054] where: q t ——t...

experiment example 1

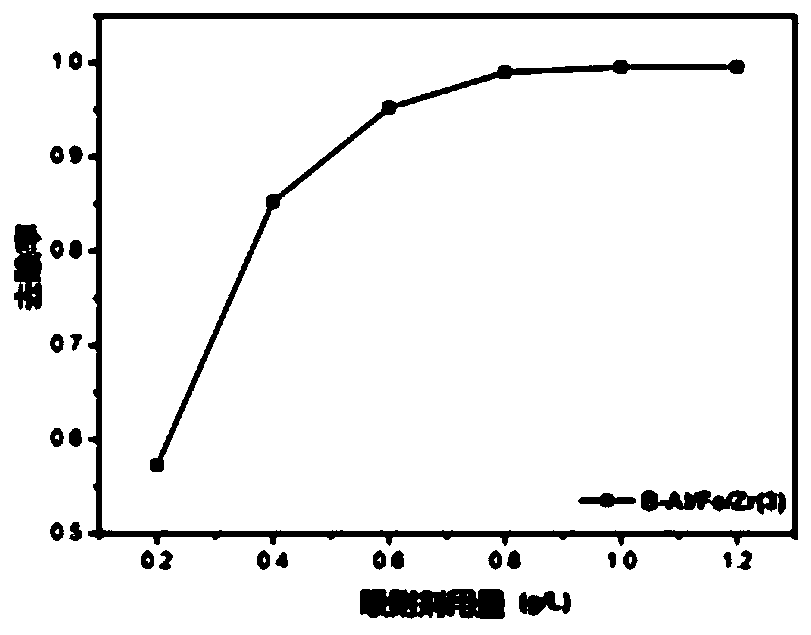

[0059] Experimental example 1: Test of the effect of the amount of iron-zirconium-aluminum combined pillared bentonite on the adsorption performance

[0060] Add 0.01, 0.02, 0.03, 0.04, 0.05, and 0.06 g of iron-zirconium-aluminum joint pillared bentonite composite samples to 50 mL of 200 mg / L crystal violet solution, shake at a speed of 175 rpm for a certain period of time, and the obtained solution Let it stand still, and take an appropriate amount of supernatant to measure the absorbance. from figure 1 It can be seen that when the dosage of the iron-zirconium-aluminum combined pillared bentonite composite sample reaches 1g / L, the maximum removal rate is reached, and the removal rate remains unchanged when more adsorbents are added, so the subsequent The data in the examples all adopt a sorbent dosage of 1 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com