Polylactic acid foamed beads and preparation method thereof

A polylactic acid foaming and polylactic acid technology, applied in the field of polylactic acid foaming beads and their preparation, can solve the problems of lack of flexibility and elasticity, low heat distortion temperature, poor heat resistance, etc., and achieve good dimensional stability, Good flame retardant properties, not easy to melt adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

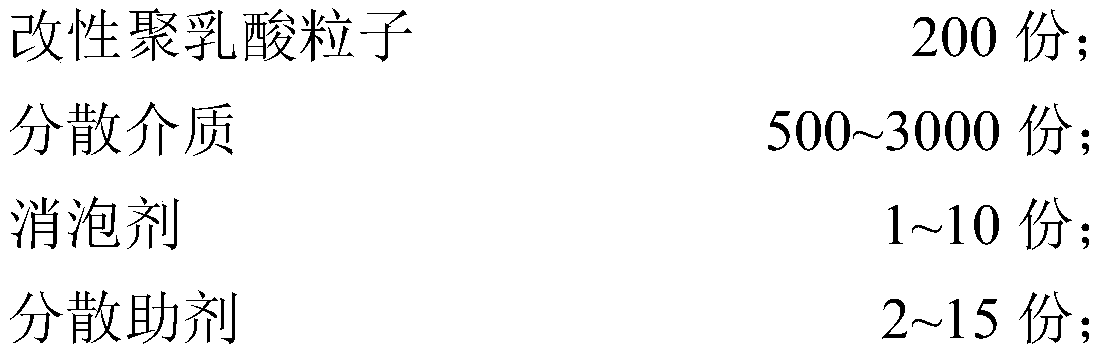

Method used

Image

Examples

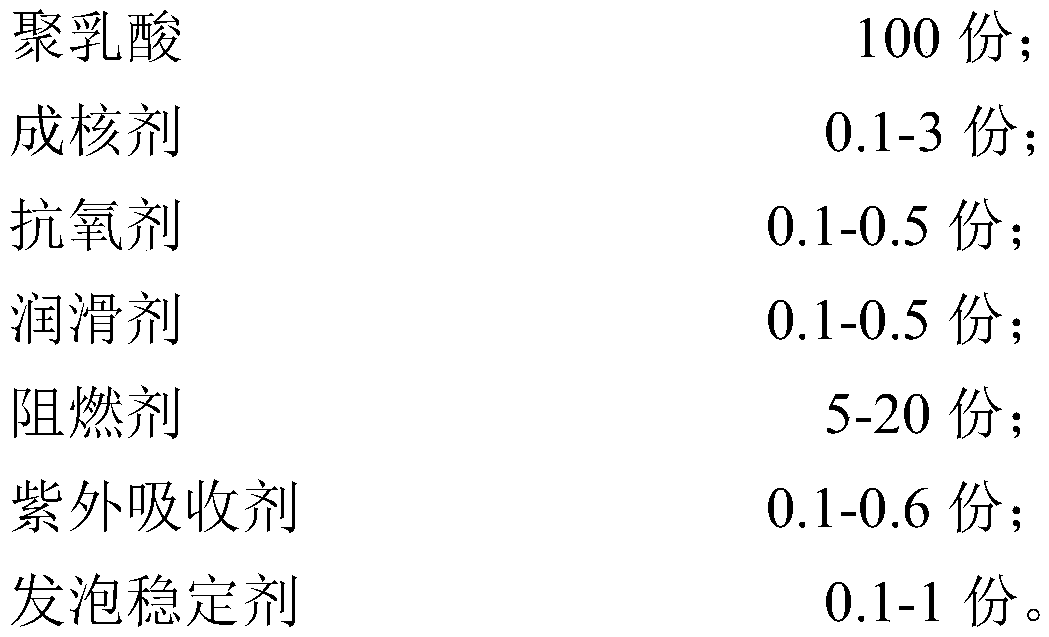

Embodiment 1

[0041] The melting point of polylactic acid is 170℃, and the melt index is 5.5g / 10min. Preparation of modified polylactic acid particles: use 100 parts of the above polylactic acid resin, 1 part of attapulgite, 0.3 part of antioxidant 1010, 0.25 part of erucamide, 15 parts of dimethyl phosphate, 2-hydroxyl-4- 0.5 part of methoxybenzophenone and 0.3 part of sodium lauryl sulfate are used to extrude modified polylactic acid particles with a length of 1-4 mm and a diameter of 0.5-2 mm through a high mixer, internal mixer and extruder.

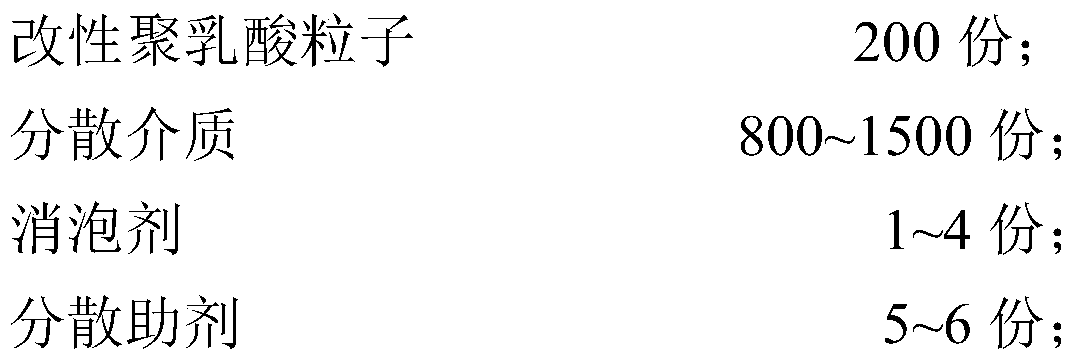

[0042] Preparation of foamed beads: Add 200g of the above modified polylactic acid particles, 1000g of deionized water, 3g of defoamer SN-DEFOAMER 1311, and 5g of chitin successively in a 5L reactor, and start stirring at a stirring speed of 100r / min. Stir for 30 minutes; use foaming gas (carbon dioxide) to discharge the residual air in the kettle, control the temperature in the reaction kettle at 125°C, inject 4MPa foaming gas (carbon dioxide), k...

Embodiment 2

[0044] The melting point of polylactic acid is 170℃, and the melt index is 5.5g / 10min. Preparation of modified polylactic acid particles: use 100 parts of the above polylactic acid resin, 1.5 parts of attapulgite, 0.3 parts of antioxidant 168, 0.25 parts of erucamide, 13 parts of dimethyl phosphate, 2-hydroxy-4 - 0.5 parts of methoxybenzophenone, 0.3 parts of sodium dodecylbenzenesulfonate, extrude modified polylactic acid with a length of 1-4mm and a diameter of 0.5-2mm through a high mixer, internal mixer, and extruder particle.

[0045] Preparation of foamed beads: Add 200g of the above modified polylactic acid particles, 1500g of deionized water, 3g of defoamer SN-DEFOAMER 1311, and 6g of chitin in a 5L reactor in turn, and start stirring at a stirring speed of 150r / min. Stir for 45 minutes; use foaming gas (carbon dioxide) to discharge the residual air in the kettle, control the temperature in the reaction kettle at 115°C, inject 6MPa foaming gas (carbon dioxide), keep t...

Embodiment 3

[0047] The melting point of polylactic acid is 160℃, and the melt index is 5g / 10min. Preparation of modified polylactic acid particles: use 100 parts of the above polylactic acid resin, 1.2 parts of attapulgite, 0.4 parts of antioxidant 1010, 0.35 parts of stearic acid amide, 13 parts of dimethyl phosphate, 2-hydroxy- 0.6 parts of 4-methoxybenzophenone and 0.3 parts of sodium oleate are used to extrude modified polylactic acid particles with a length of 1-4 mm and a diameter of 0.5-2 mm through a high mixer, internal mixer and extruder.

[0048] Preparation of foamed beads: Add 150 g of the above modified polylactic acid particles, 800 g of deionized water, 1.6 g of defoamer SN-DEFOAMER 1311, and 6 g of chitin in turn in a 3L reactor and start stirring at a stirring speed of 100 r / min , Stir for 45 minutes; use foaming gas (carbon dioxide) to discharge the residual air in the kettle, control the temperature in the reaction kettle at 115°C, inject 9MPa foaming gas (carbon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com