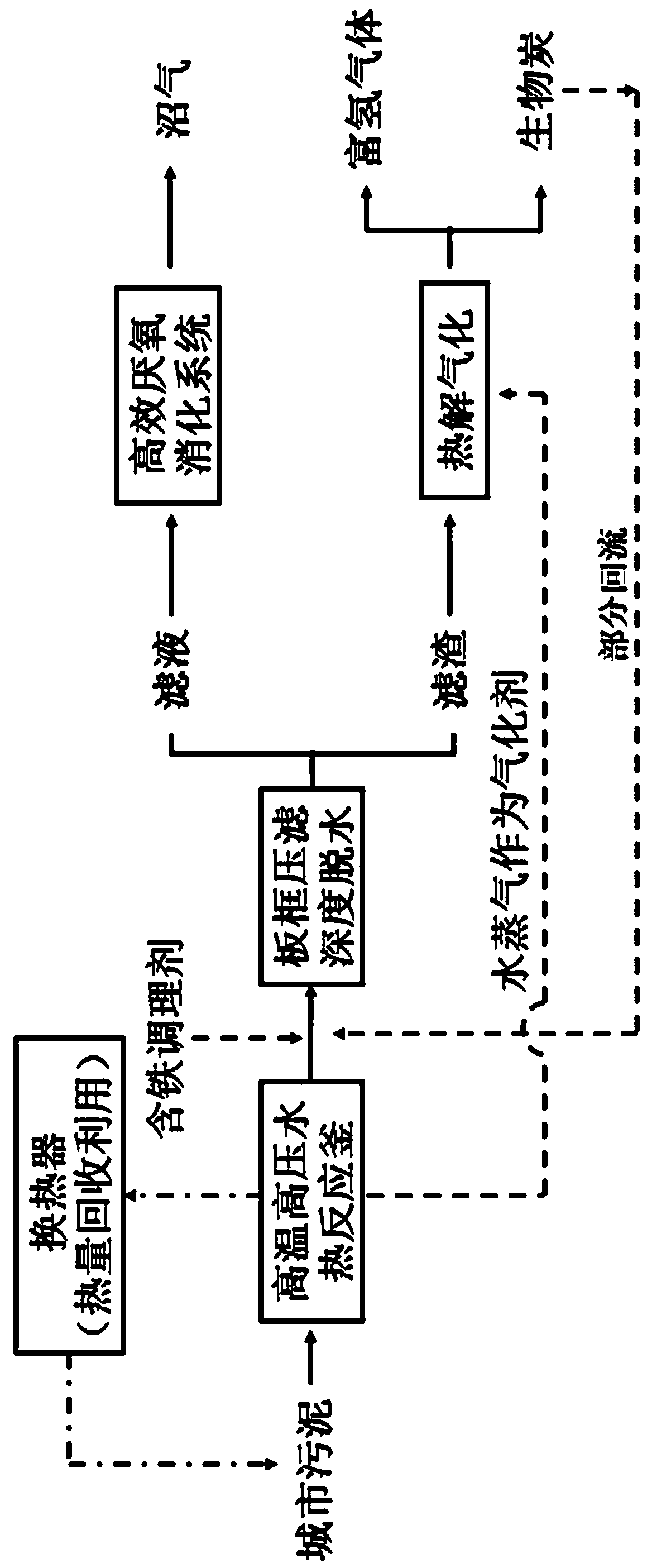

Efficient sludge energy treatment method based on hydrothermal pretreatment

A treatment method and high-efficiency energy technology, applied in pyrolysis treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of reduced thermal sludge gasification effect, and reduce energy consumption and Chemical cost, carbon emission reduction, dehydration performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The pyrolysis gasification of the dewatered sludge and the preparation of the catalyst are carried out simultaneously. The iron-containing conditioner and biochar conditioner remaining in the mud cake are evenly distributed inside the sludge particles, increasing the content of Fe, C and other elements in the sludge, and its effects from two aspects:

[0046] In the preparation of hydrogen-rich gas fuel, iron salt can effectively increase the reaction rate of sludge gasification, biochar can supplement the C source and increase the CO, CH 4 and other gas production. Higher active biochar can promote the breaking of carbon-hydrogen bonds and carbon-carbon bonds on the surface of sludge particles, promote the transformation of macromolecular organic matter into small molecular gases, and promote the formation of voids in particulate matter, increasing the specific surface area of sludge particles. At the same time, biochar can catalyze the cracking of pyrolysis oil, pr...

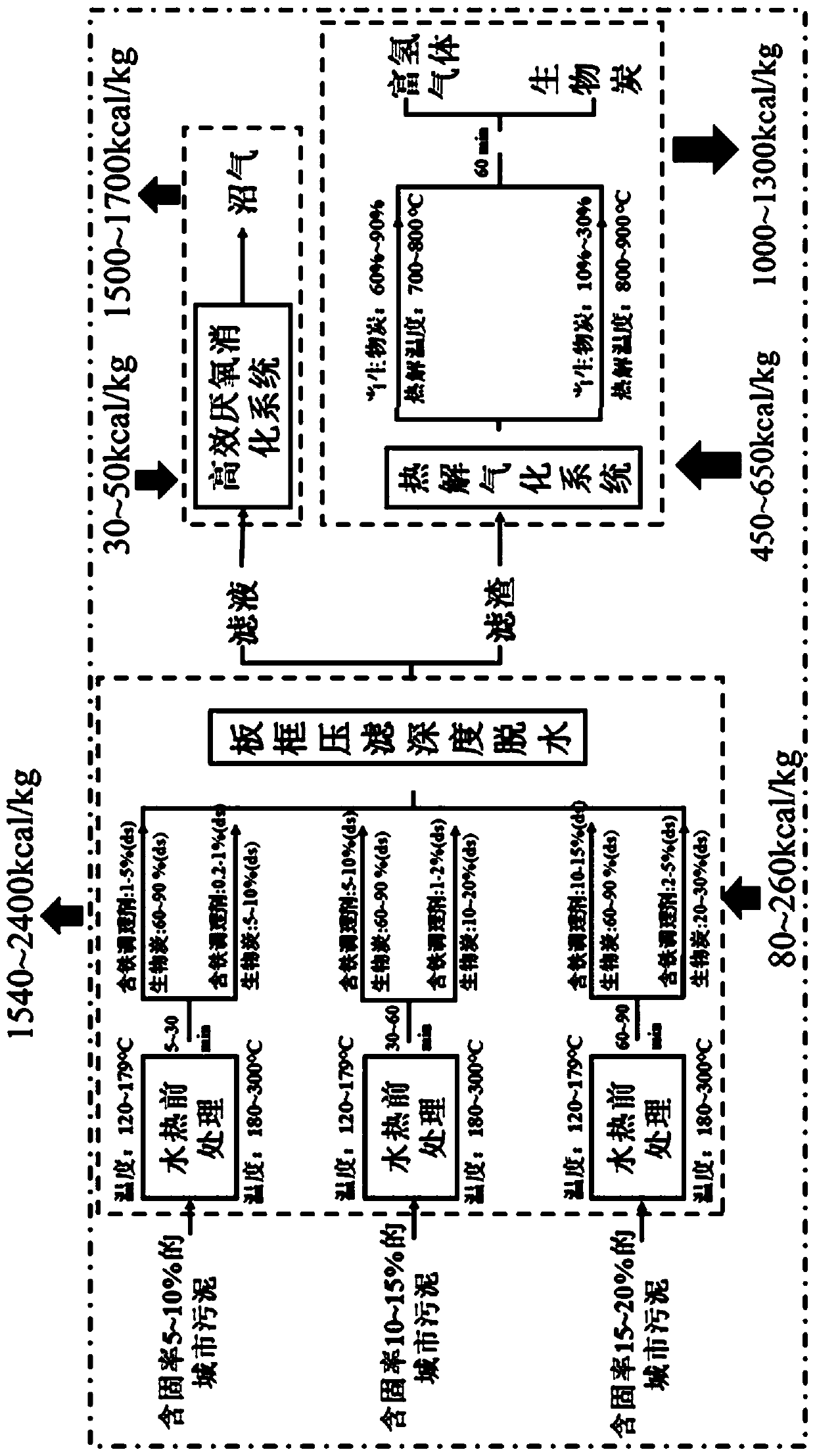

Embodiment 1

[0049] The dewatered sludge of a sewage treatment plant has a measured solid content of 10%. Put 80kg of sludge in the sludge storage tank into the inner tank of a hydrothermal reaction kettle with an effective volume of 100L. The set temperature is 180°C and the pressure is 1MPa, maintain 30min after reaching the set temperature, water vapor is recovered and used to preheat the sludge in the sludge storage tank, the solid content of the sludge is reduced to 6% after hydrothermal treatment, and solid FeSO is added to the sludge after hydrothermal treatment 4 , the dosage is 2% of the dry weight of the sludge, mixed evenly and stirred for 10 minutes; then add 0.15g / g (DS) biochar produced by subsequent pyrolysis and gasification, and the water content of the mud cake obtained after dehydration by plate and frame filtration The filtrate enters the anaerobic digestion system to produce methane and collect biogas, and the wet mud cake produced enters the sequencing batch fixed-bed ...

Embodiment 2

[0051] The dewatered sludge of a sewage treatment plant has a measured solid content of 20%. The sludge is semi-continuously entered into a hydrothermal reactor with a temperature of 200°C and a pressure of 1.6MPa through a high-pressure pump. After reaching the set temperature Maintained for 60 minutes, water vapor was recovered and used to preheat the sludge in the sludge storage tank. It was measured that the solid content of the sludge after hydrothermal modification was reduced to 15%, and solid FeSO was added to the sludge after hydrothermal treatment 4 , the dosage is 5% of the dry weight of the sludge, mixed evenly and stirred for 10 minutes; then add 0.27g / g (DS) of biochar produced by subsequent pyrolysis and gasification, and the moisture content of the mud cake obtained after dehydration by plate and frame filtration The reaction material enters the dehydration system after multi-stage decompression cooling, the dehydration filtrate enters the anaerobic system for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com