Electromagnetic shielding geopolymer composite material, and preparation method and application thereof

A composite material and geopolymer technology, used in cement production and other directions, can solve the problems of poor dispersion of conductive fillers, and achieve the effects of low cost, excellent electromagnetic shielding function and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044](1) First prepare a mixed solution of 180 mL of sulfuric acid (Sinopharm Group Chemical Reagent Co., Ltd., national drug code: 10021628) and 60 mL of nitric acid (Shanghai Titan Science and Technology Co., Ltd., product number: 10014528) with a volume ratio of 3:1 in a container. Add 1.5 g of carbon nanotubes (Nanjing Xianfeng Nano Material Technology Co., Ltd., article number: 100253) into 240 mL of mixed acid solution, and stir for 2.5 h. Then perform vacuum filtration and wash repeatedly with deionized water until the pH value of the carbon nanotubes is 7.0. The washed black powder was freeze-dried in a freeze dryer FD-1C-50 (Beijing Boyikang Experimental Instrument Co., Ltd.) for 48 hours to obtain dry and fluffy acidified carbon nanotube powder.

[0045] (2) prepare the mixed solution of absolute ethanol (Sinopharm Group Chemical Reagent Co., Ltd., national drug code: 10009228) and ammonia (Sinopharm Group Chemical Reagent Co., Ltd., national drug code: 10002128) wi...

Embodiment 2

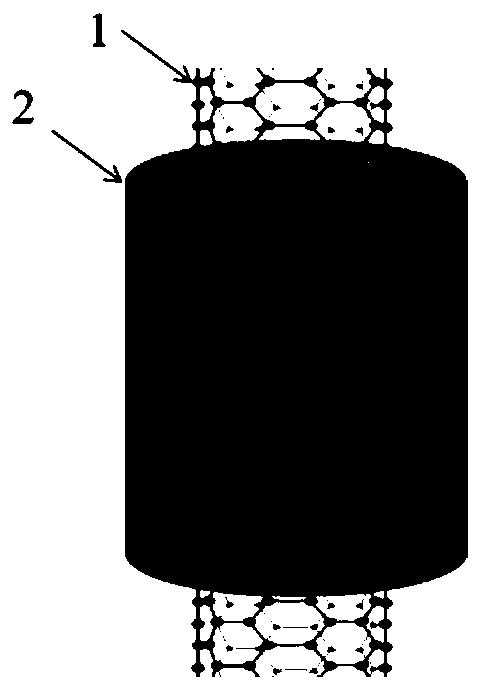

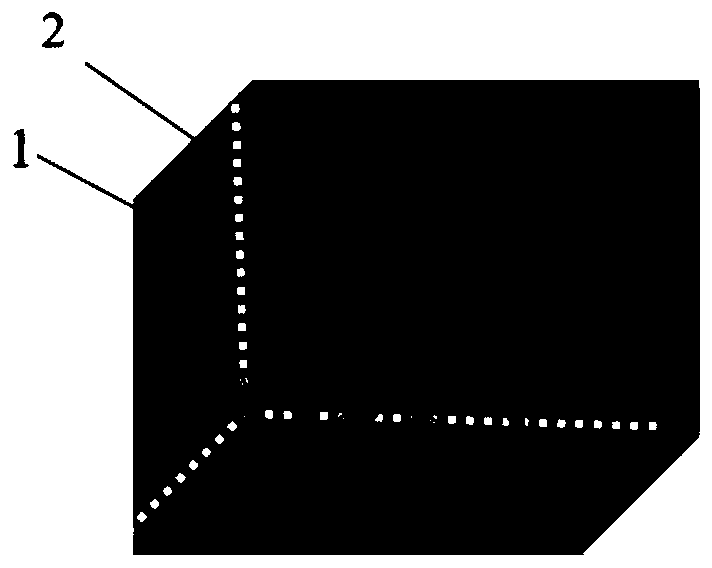

[0053] Mix sodium silicate solution (Merck, Germany, product number: 338443-1L) with 1.5 g of sodium hydroxide particles (Shanghai Titan Technology Co., Ltd., product number: G19852K) at a weight ratio of 90:10 to obtain the sodium ion concentration It is an alkaline solution of 8mol / L. Add 0.35 g of the surface-treated carbon nanotubes in Example 1 to the above-prepared 10 mL of alkaline solution and ultrasonically disperse them for 30 minutes, and then mix them with the metakaolin whose weight ratio of the surface-treated carbon nanotubes is 100:3 , and then rotated at a speed of 2000r / min for 5min in a stirrer ARE-310 (Thinky Corporation, Japan) to obtain a homogeneously mixed slurry. Pour the slurry into a Teflon mold and seal the mold with tape. Then move the mold to an oven, solidify at 60°C for 24 hours, and demould after natural cooling to obtain a geopolymer composite ( figure 1 marked as (2)).

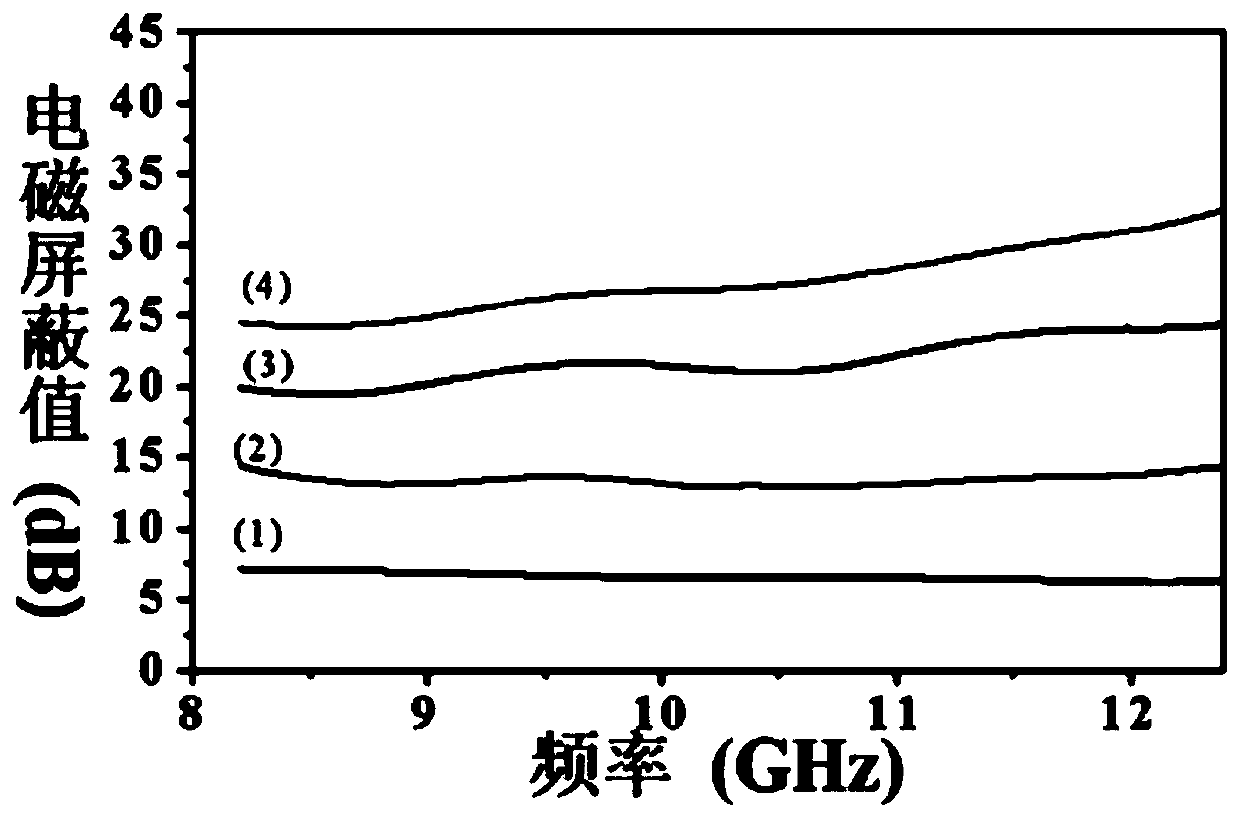

[0054] The geopolymer composite material ( figure 1 marked as (1))...

Embodiment 3

[0059] Mix sodium silicate solution (Merck, Germany, product number: 338443) with 2.0 g sodium hydroxide particles (Shanghai Titan Technology Co., Ltd., original product number: G19852K) in a weight ratio of 95:5 to obtain a sodium ion concentration of 10 mol / L alkaline solution. 0.5 g of the surface-treated carbon nanotubes in Example 1 were added to the above-prepared alkaline solution for ultrasonic dispersion for 30 minutes, and then mixed with metakaolin whose weight ratio of the surface-treated carbon nanotubes was 10:1, and then Rotate at a speed of 2000r / min for 5min in a stirrer ARE-310 (Thinky Corporation, Japan) to obtain a uniformly mixed slurry. Pour the slurry into a Teflon mold and seal the mold with tape. Then move the mold to an oven, solidify at 60°C for 24 hours, and demould after natural cooling to obtain a geopolymer composite ( figure 1 marked as (4)).

[0060] The geopolymer composite material ( figure 1 marked as (3)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com