A kind of polyester elastomer film and preparation method thereof

A polyester elastomer and film technology, applied in the field of polyester elastomer film and its preparation, can solve the problems of refractory polymer film, waste of crop straw and waste, etc., to expand utilization, improve mechanical properties, and expand application scope Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

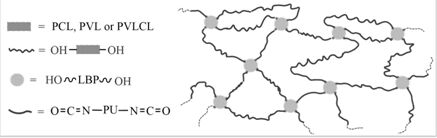

Method used

Image

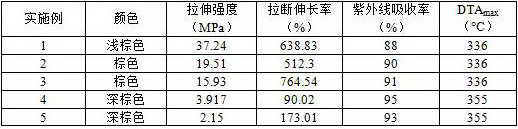

Examples

Embodiment 1

[0024] (1) Put 20 g of polyethylene glycol (molecular weight 400) and 5 g of glycerin into a three-necked flask and mix them, place them in an oil bath at 140 °C, add 1.75 g of concentrated sulfuric acid (98%) and 5 g of straw powder ( 50 mesh), stirred and reacted for 120 min. After the reaction, the reaction mixture was diluted with absolute ethanol, washed, filtered through a Buchner funnel to remove the residue, and the filtrate was removed by rotary evaporation (0.5 mbar, 65 ℃, 1 h). water ethanol to obtain straw liquefaction;

[0025] (2) Under a nitrogen atmosphere, take 1.5 g of straw liquefaction in a reaction flask, raise the temperature to 70 °C, add 7.5 mg of the catalyst stannous isooctanoate and 4 g of hexamethylene diisocyanate dropwise into the reaction flask, and stir magnetically After reacting for 3 h, a polyurethane prepolymer was generated, and 2.96 g of polycaprolactone diol was added, and the reaction was continued for 5 h to obtain a casting solution. ...

Embodiment 2

[0027] (1) Put 20 g of polyethylene glycol (molecular weight 400) and 5 g of glycerin into a three-necked flask and mix them, place them in an oil bath at 140 °C, add 1.75 g of concentrated sulfuric acid (98%) and 5 g of straw powder ( 50 mesh), stirred and reacted for 120 min. After the reaction, the reaction mixture was diluted with absolute ethanol, washed, filtered through a Buchner funnel to remove the residue, and the filtrate was removed by rotary evaporation (0.5 mbar, 65 ℃, 1 h). water ethanol to obtain straw liquefaction;

[0028] (2) Under a nitrogen atmosphere, take 2 g of straw liquefaction in a reaction flask, raise the temperature to 70 °C, add 10 mg of the catalyst stannous isooctanoate and 4 g of hexamethylene diisocyanate dropwise into the reaction flask, and magnetically stir After reacting for 3 h, a polyurethane prepolymer was generated, and 2.96 g of polycaprolactone diol was added, and the reaction was continued for 5 h to obtain a casting solution. Pla...

Embodiment 3

[0030] (1) Put 20 g of polyethylene glycol (molecular weight 400) and 5 g of glycerin into a three-necked flask and mix them, place them in an oil bath at 140 °C, add 1.75 g of concentrated sulfuric acid (98%) and 5 g of straw powder ( 50 mesh), stirred and reacted for 120 min. After the reaction, the reaction mixture was diluted with absolute ethanol, washed, filtered through a Buchner funnel to remove the residue, and the filtrate was removed by rotary evaporation (0.5 mbar, 65 ℃, 1 h). water ethanol to obtain straw liquefaction;

[0031] (2) Under a nitrogen atmosphere, take 2.5 g of liquefied straw in a reaction flask, raise the temperature to 70 °C, add 10 mg of the catalyst stannous isooctanoate and 4 g of hexamethylene diisocyanate dropwise into the reaction flask, and magnetically stir After reacting for 3 h, a polyurethane prepolymer was generated, and 2.96 g of polycaprolactone diol was added, and the reaction was continued for 5 h to obtain a casting solution. Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com