Method for continuous countercurrent extraction of long-chain fatty alcohol in alkyl glycoside crude product

A technology for alkyl glycosides and fatty alcohols, which is applied in the field of continuous countercurrent extraction of long-chain fatty alcohols in crude alkyl glycosides, can solve the problems of increased processing steps and production costs, complicated separation process steps, difficult industrial application and the like, and achieves extraction regulation. No pollution, strong extraction ability, mild extraction adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

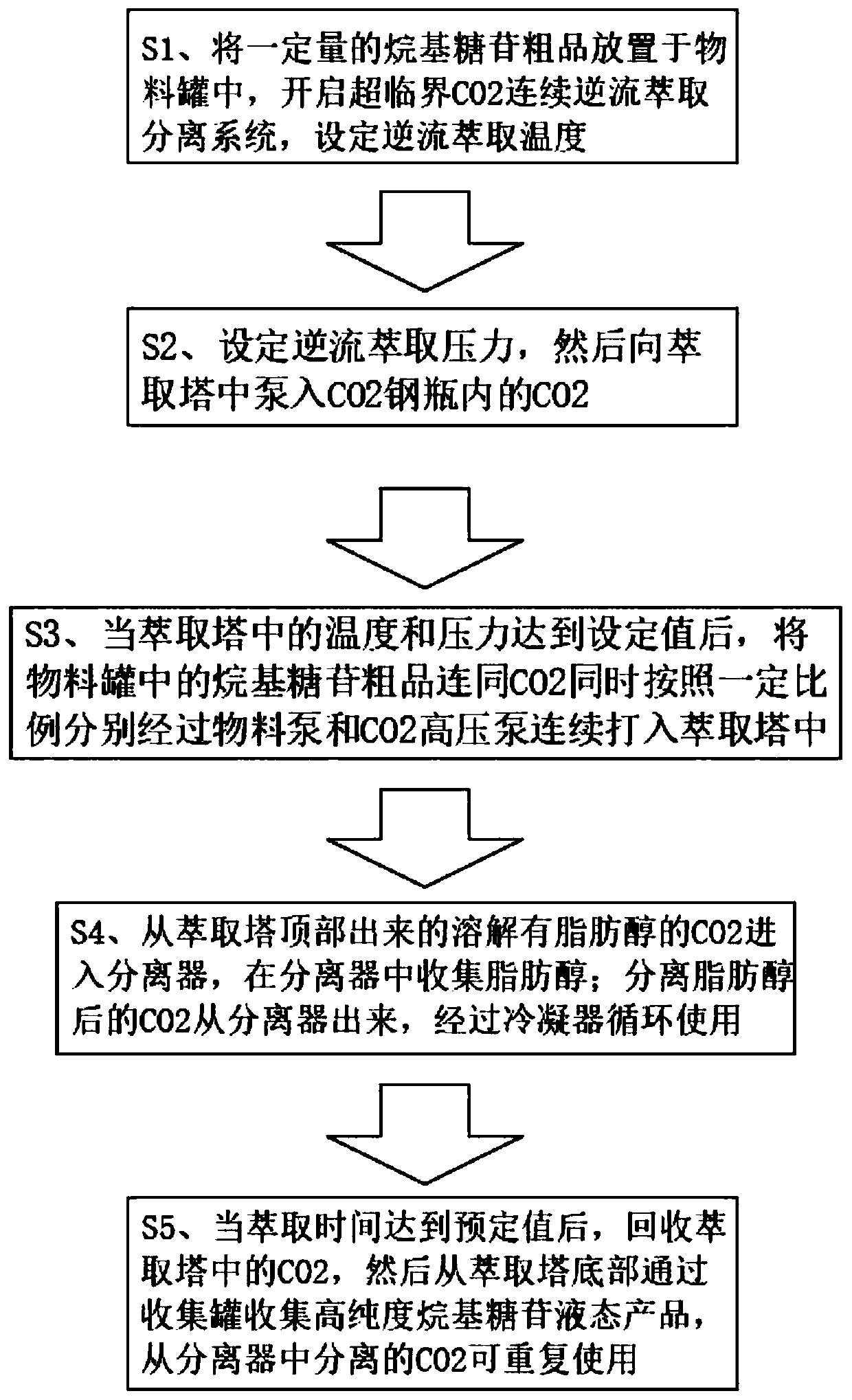

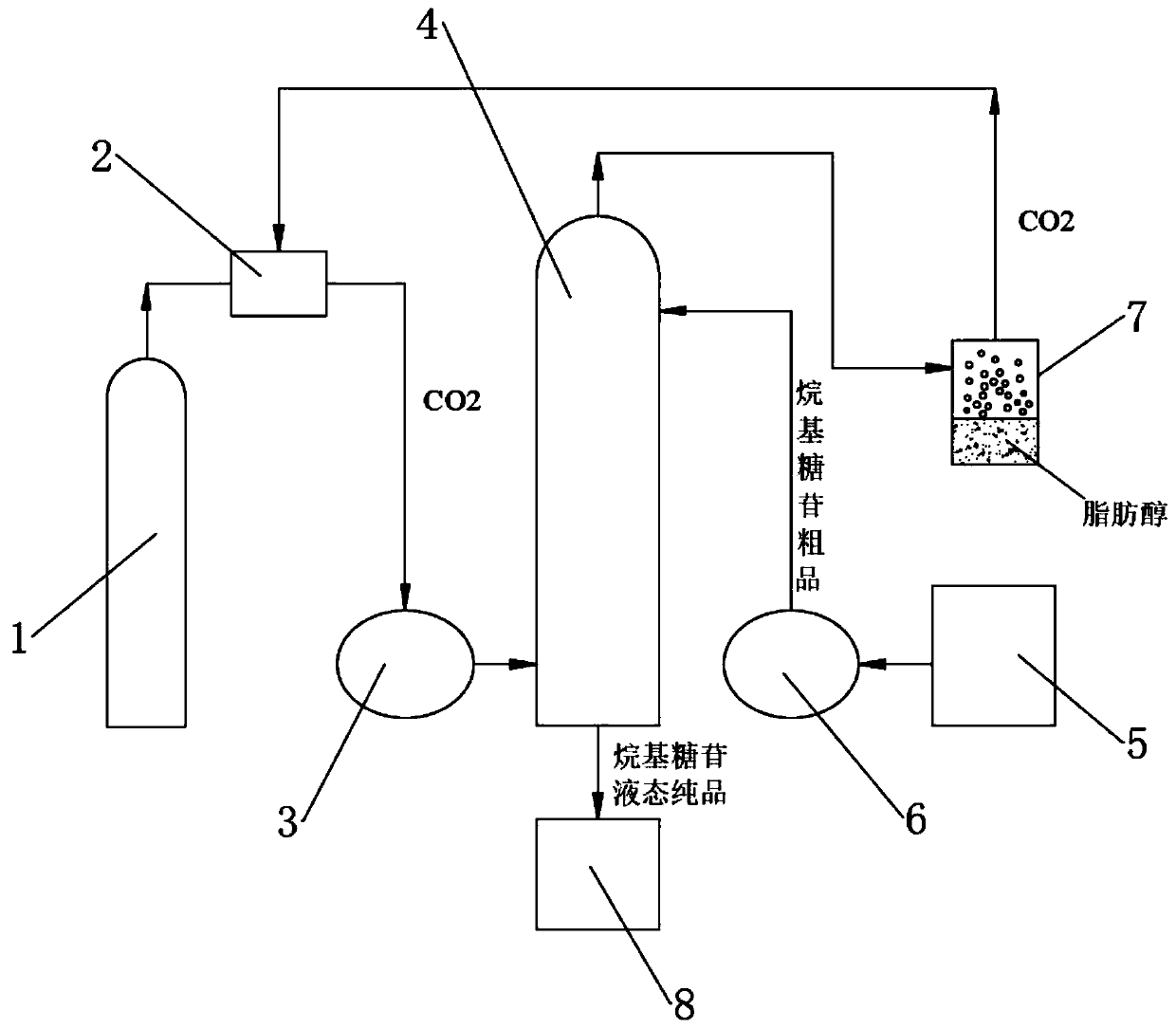

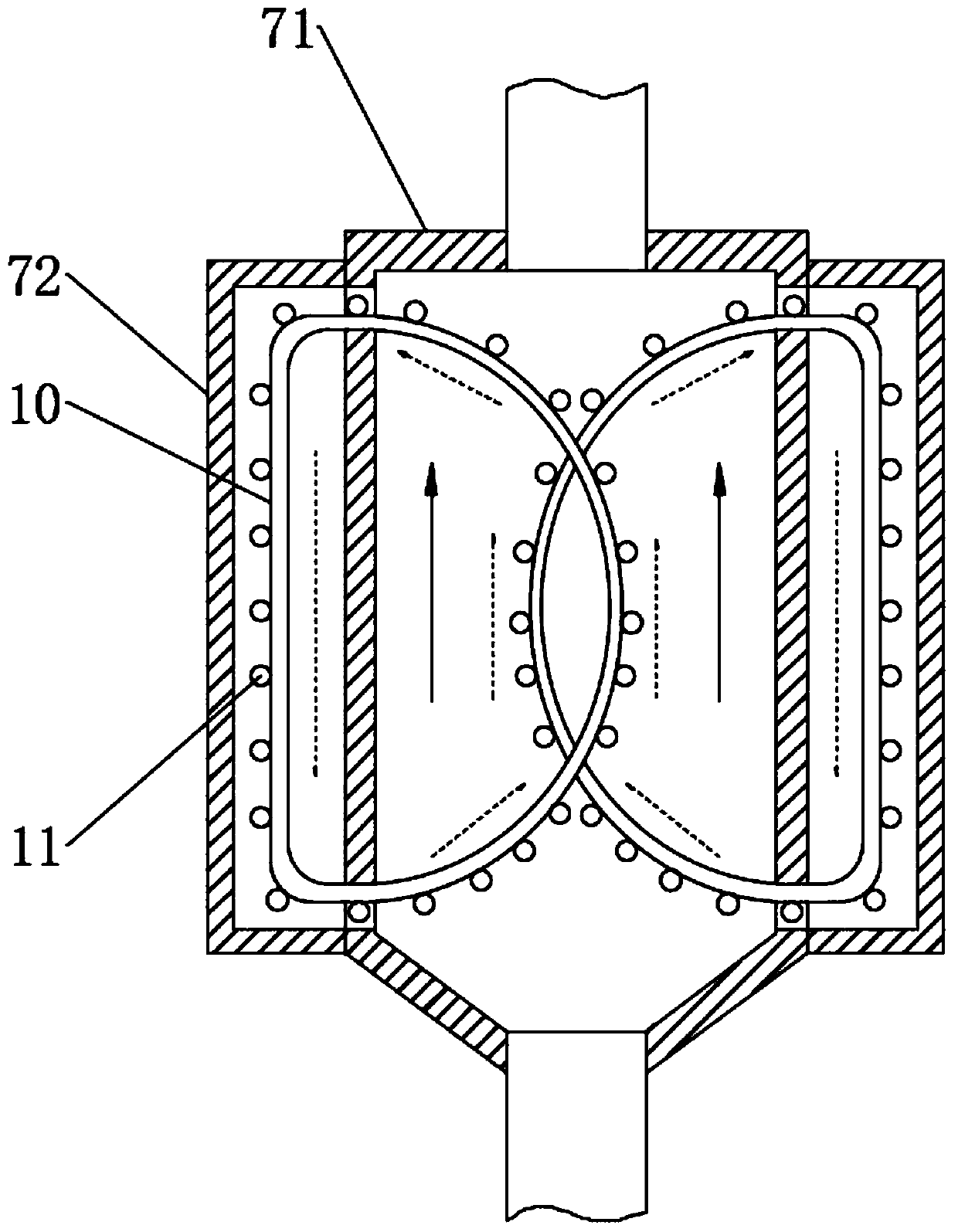

[0043] see Figure 1-2 , put 2000 grams of crude alkyl glycosides into the material tank 6, the crude alkyl glycosides are pumped into the extraction tower 4 through the material pump 5, and at the same time, CO2 comes out of the CO2 cylinder 1 and is pumped into the condenser 2 with the CO2 high-pressure pump 3 In the extraction tower, the temperature and pressure of the extraction tower are 55°C and 15MPa respectively, and the weight ratio of the crude alkyl glycoside material to CO2 is 1:10. During the continuous countercurrent extraction process, the fatty alcohol comes out of the extraction tower along with CO2 into the Separator 7, after the fatty alcohol is separated in the separator, CO2 is recycled through the condenser, and the liquid product of alkyl glycosides that removes the fatty alcohol is collected from the bottom of the extraction tower. During the continuous feeding process, the fatty alcohol and alkyl glycoside products are collected from the separator and ...

Embodiment 2

[0049] see Figure 1-2 , put 2000 grams of crude alkyl glycosides into the material tank 6, the crude alkyl glycosides are pumped into the extraction tower 4 through the material pump 5, and at the same time, CO2 comes out of the CO2 cylinder 1 and is pumped into the condenser 2 with the CO2 high-pressure pump 3 In the extraction tower, the temperature and pressure of the extraction tower are 60°C and 25MPa respectively, and the weight ratio of the crude alkyl glycoside material to CO2 is 1:8. During the continuous countercurrent extraction process, the fatty alcohol comes out of the extraction tower along with CO2 into the Separator 7, after the fatty alcohol is separated in the separator, CO2 is recycled through the condenser, and the liquid product of alkyl glycosides that removes the fatty alcohol is collected from the bottom of the extraction tower. During the continuous feeding process, the fatty alcohol and alkyl glycoside products are collected from the separator and t...

Embodiment 3

[0052] see Figure 1-2 , put 2000 grams of crude alkyl glycosides into the material tank 6, the crude alkyl glycosides are pumped into the extraction tower 4 through the material pump 5, and at the same time, CO2 comes out of the CO2 cylinder 1 and is pumped into the condenser 2 with the CO2 high-pressure pump 3 In the extraction tower, the temperature and pressure of the extraction tower are 65°C and 30MPa respectively, and the weight ratio of the crude alkyl glycoside material to CO2 is 1:7. During the continuous countercurrent extraction process, the fatty alcohol comes out of the extraction tower along with CO2 into the Separator 7, after the fatty alcohol is separated in the separator, CO2 is recycled through the condenser, and the liquid product of alkyl glycosides that removes the fatty alcohol is collected from the bottom of the extraction tower. During the continuous feeding process, the fatty alcohol and alkyl glycoside products are collected from the separator and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com