A crystal growth method based on vgf method for vapor phase doping

A technology of crystal growth and gas phase doping, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of destroying crystal uniformity and integrity, uneven distribution of Fe, reducing device performance, etc., to improve uniformity performance and crystallization rate, cost saving, and the effect of reducing the amount of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

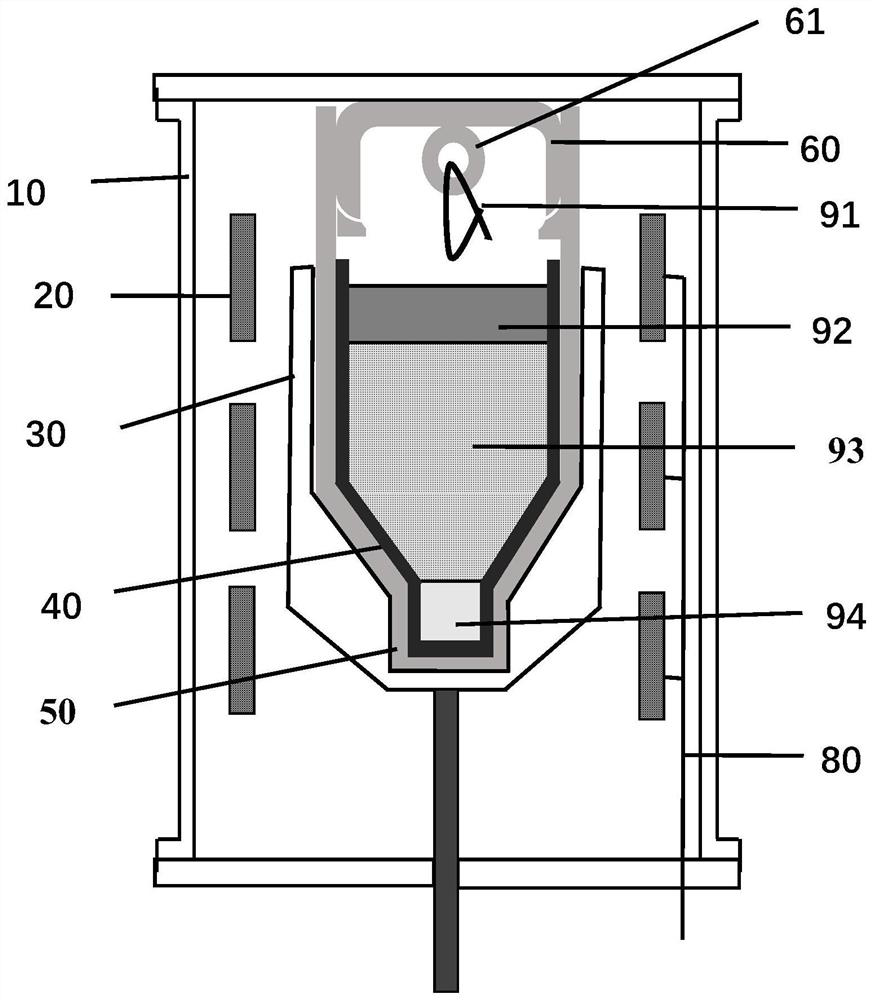

[0052] In combination with 1 and 2, this embodiment provides a crystal growth device and a crystal growth method for growing an indium phosphide single crystal by vapor phase doping of iron element based on the VGF method.

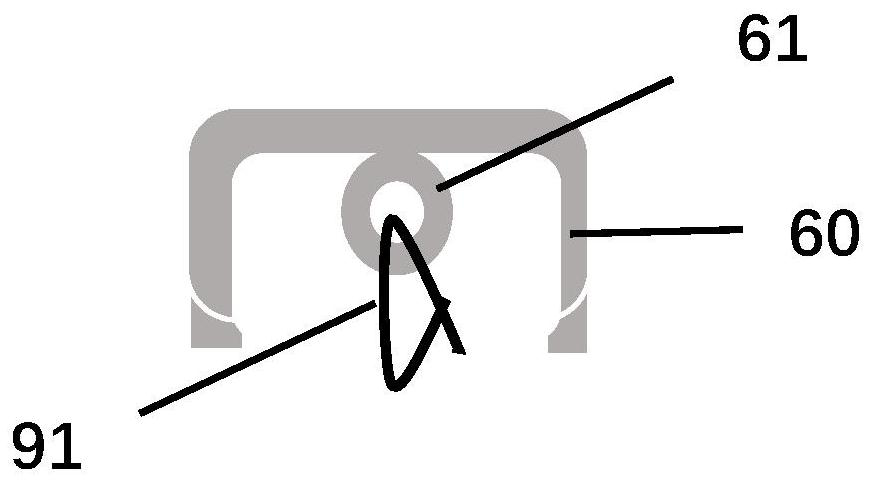

[0053] Among them, such as figure 2 , the crystal growth device comprises a growth furnace 10, a graphite crucible holder 20, a boron nitride crucible 40, a quartz tube 50, and a quartz cap 60; several heating devices 30 are sequentially arranged in the growth furnace 10 from bottom to top; each heating device passes The galvanic couple 80 is connected to the control system; the graphite crucible holder 20 is located in the growth furnace 10 . Wherein the bottom of the boron nitride crucible 40 has a seed crystal plug for carrying the seed crystal.

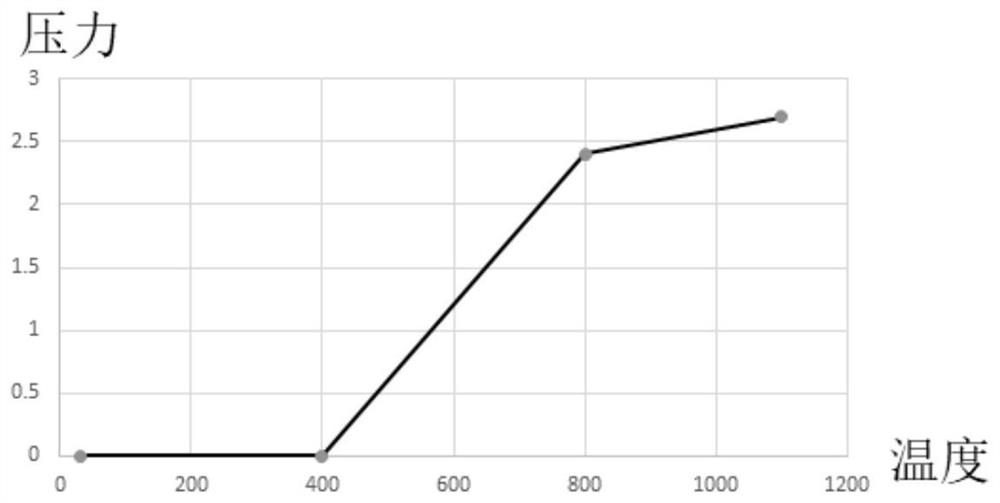

[0054] During crystal growth, various raw materials are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com