Preparation method of flaky hydroxyapatite carrier and preparation method of supported nano-silver catalyst

A technology of hydroxyapatite and carrier, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of poor thermal stability, uncontrollable shape, and amorphous structure of supported nano-silver catalysts , to achieve low raw material prices, improve catalytic performance, and enhance the effect of anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] At room temperature, (1) Dissolve 1.6130g of sodium hydroxide and 4.2028g of citric acid in 20mL of water and place on a magnetic stirrer to dissolve them all; (2) Dissolve 2.365g of calcium nitrate in 20mL of water and place on a magnetic stirrer Put it on the stirrer, dissolve it and pour it into (1); (3) dissolve 0.7923g of diammonium hydrogen phosphate in 28mL of water, pour it into the mixture of (1) and (2), then add 3.0300g in a water bath at 30°C Urea, stirred for 30min, then moved the solution into a 100mL stainless steel autoclave with polytetrafluoroethylene lining, heated it in water at 160°C for 12h, then lowered to room temperature, centrifuged the white precipitated product, washed three times with water, and washed once with alcohol until Neutral, dried in an oven at 50°C to obtain a HAP material with a two-dimensional sheet structure.

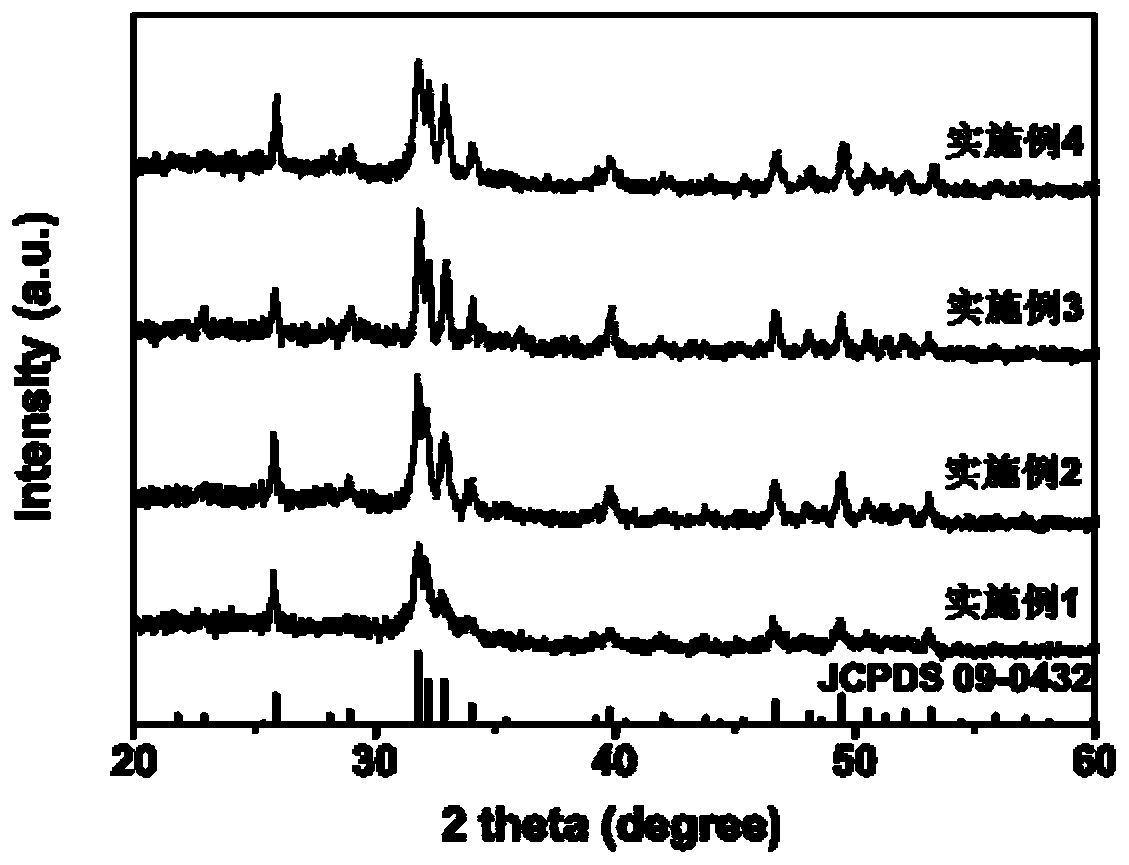

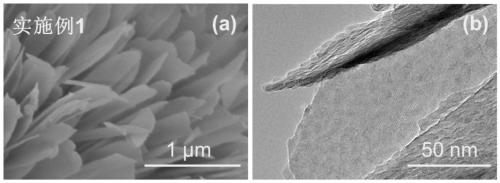

[0061] Such as figure 1 As shown, the synthesized HAP nanosheets have obvious HAP characteristic peaks (No.09-0432), ...

Embodiment 2

[0063] At room temperature, (1) Dissolve 1.6130g of sodium hydroxide and 4.2028g of citric acid in 20mL of water and place on a magnetic stirrer to dissolve them all; (2) Dissolve 2.365g of calcium nitrate in 20mL of water and place on a magnetic stirrer Put it on the stirrer, dissolve it and pour it into (1); (3) dissolve 0.7923g of diammonium hydrogen phosphate in 28mL of water, pour it into the mixture of (1) and (2), then add 3.0300g in a water bath at 30°C Urea, stirred for 30min, then moved the solution into a 100mL stainless steel autoclave with polytetrafluoroethylene lining, heated it with water at 180°C for 12h, then lowered to room temperature, centrifuged the white precipitated product, washed three times with water, and washed once with alcohol until Neutral, dried in an oven at 50°C to obtain a HAP material with a two-dimensional sheet structure.

[0064] Such as Figure 4 As shown, the size of the synthesized HAP nanosheets is irregular and increased, and the t...

Embodiment 3

[0066] At room temperature, (1) Dissolve 2.4198g of sodium hydroxide and 6.3042g of citric acid in 20mL of water and place on a magnetic stirrer to dissolve them all; (2) Dissolve 2.365g of calcium nitrate in 20mL of water and place on a magnetic stirrer Put it on the stirrer, dissolve it and pour it into (1); (3) dissolve 0.7923g of diammonium hydrogen phosphate in 28mL of water, pour it into the mixture of (1) and (2), then add 3.0300g in a water bath at 30°C Urea, stirred for 30min, then moved the solution into a 100mL stainless steel autoclave with polytetrafluoroethylene lining, heated it with water at 180°C for 12h, then lowered to room temperature, centrifuged the white precipitated product, washed three times with water, and washed once with alcohol until Neutral, dried in an oven at 50°C to obtain a HAP material with a two-dimensional sheet structure.

[0067] Such as Figure 5 As shown, the synthesized HAP nanosheets are larger in size with a thickness of 100-150 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com