Preparation method and application of silicotungstic acid shell coating and core intercalation zeolite imidazole framework

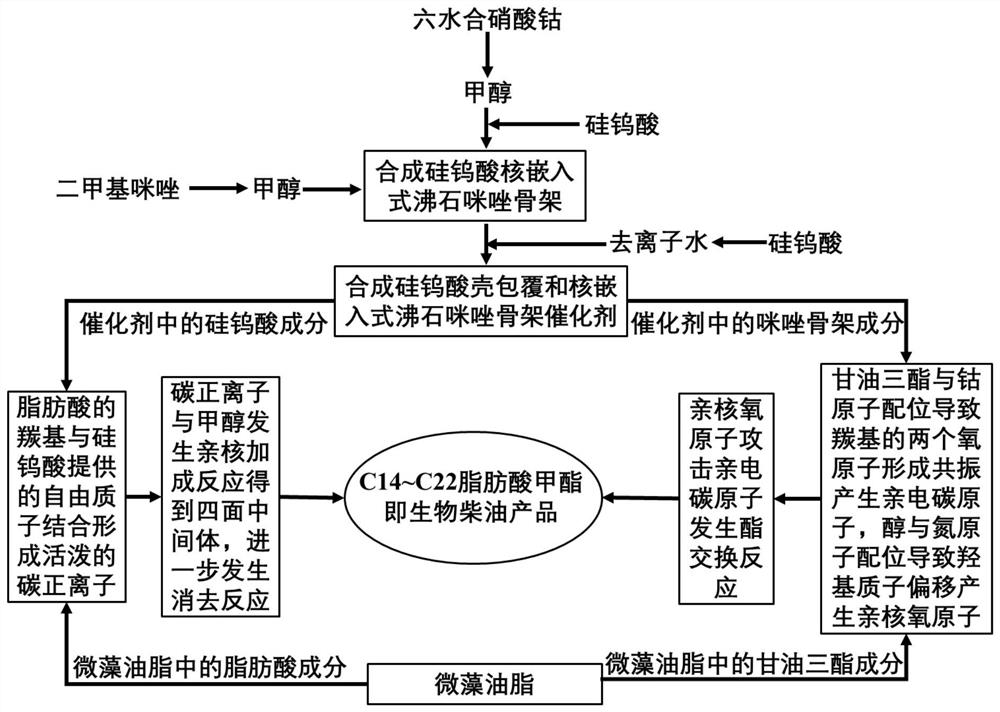

A technology of zeolite imidazole framework and silicotungstic acid, applied in chemical instruments and methods, catalytic reactions, fatty acid esterification, etc., can solve the problem of zeolite imidazole framework collapse, transesterification catalytic efficiency is not significantly improved, and the catalytic efficiency is only 60% and other issues to achieve good stability, avoid equipment corrosion and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 0.72g of cobalt nitrate hexahydrate and 1.63g of dimethylimidazole and dissolve them in 50mL of methanol respectively. After dissolving 0.1g of silicotungstic acid in cobalt nitrate methanol solution, slowly add it into dimethylimidazole methanol solution (adding speed is 50mL / min), and keep stirring at 100rpm at room temperature for 12h. Centrifuge after the complexation reaction is complete, filter the solid and wash it with deionized water for 3 times, and then dry it in a 60°C oven for 6 hours to obtain the silicotungstic acid core-embedded zeolite imidazole framework.

[0025] Dissolve 0.2g of silicotungstic acid in 10mL of deionized water, add 0.3g of the silicotungstic acid core-embedded zeolite imidazole skeleton obtained above into the aqueous solution of silicotungstic acid, ultrasonicate for 30min, and continue stirring at room temperature at 100rpm for 24h. After fully reacting, centrifuge, filter out the solid and wash it with deionized water for 3 tim...

Embodiment 2

[0028] Take 7.2g of cobalt nitrate hexahydrate and 16.3g of dimethylimidazole and dissolve them in 500mL of methanol respectively. Take 1g of silicotungstic acid and dissolve it in cobalt nitrate methanol solution, slowly add it into dimethylimidazole methanol solution (adding speed is 50mL / min), and keep stirring at 500rpm at room temperature for 12h. Centrifuge after the complexation reaction is complete, filter the solid and wash it with deionized water for 3 times, and then dry it in an oven at 100°C for 10 hours to obtain the silicotungstic acid core-embedded zeolite imidazole framework.

[0029] Dissolve 2g of silicotungstic acid in 50mL of deionized water, add 3g of the silicotungstic acid core-embedded zeolite imidazole skeleton obtained above into the aqueous solution of silicotungstic acid, ultrasonicate for 30min, and continue stirring at room temperature at 500rpm for 24h. After fully reacting, centrifuge, filter out the solid, wash it with deionized water for 3 ti...

Embodiment 3

[0032] Take 3.6g of cobalt nitrate hexahydrate and 8.1g of dimethylimidazole and dissolve them in 250mL of methanol respectively. After dissolving 0.5g of silicotungstic acid in cobalt nitrate methanol solution, slowly add it into dimethylimidazole methanol solution (adding speed is 50mL / min), and keep stirring at 300rpm at room temperature for 12h. Centrifuge after the complexation reaction is complete, filter the solid and wash it with deionized water for 3 times, then dry it in an oven at 80°C for 8 hours to obtain the silicotungstic acid core-embedded zeolite imidazole framework.

[0033] Dissolve 1 g of silicotungstic acid in 25 mL of deionized water, add 1.5 g of the silicotungstic acid core-embedded zeolite imidazole skeleton obtained above into the aqueous solution of silicotungstic acid, ultrasonicate for 30 minutes, and continue stirring at room temperature at 300 rpm for 24 hours. After fully reacting, centrifuge, filter out the solid and wash it with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com