Degradable and thermoplastically processable epoxy thermosetting resin and preparation method thereof

A thermoplastic processing and thermosetting technology, which is applied in the field of epoxy vitrimers and its preparation, can solve the problems of non-reversible properties, epoxy thermosetting resins cannot be thermoplastically processed, and high energy consumption for carbon fiber recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

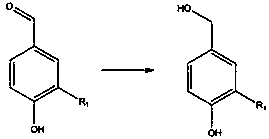

[0029] (1) Mix 10 parts by weight of vanillin, 10 parts by weight of sodium borohydride or sodium cyanoborohydride and 100 parts by weight of methanol, and react at room temperature for 2 hours. After confirming that the reaction is complete by thin layer chromatography, use 10 After quenching the reaction with 1 mol / L sodium hydrosulfide aqueous solution in parts by weight, the reaction solution was concentrated and then added with ethyl acetate to extract the product, the organic phase was retained by liquid separation, and the organic phase was collected after drying with anhydrous sodium sulfate, and obtained by rotary evaporation Product I.

[0030] (2) Add 10 parts by weight of product I to 100 parts by weight of xylene, then add 10 parts by weight of modified monomer II tert-butyl acetoacetate, heat to 130°C for 5 hours, and remove xylene by vacuum distillation. Separated by column chromatography, the eluent is ethyl acetate / petroleum ether or dichloromethane / ethyl acet...

Embodiment 2

[0037] (1) After mixing 10 parts by weight of p-hydroxybenzaldehyde, 10 parts by weight of sodium borohydride or sodium cyanoborohydride and 100 parts by weight of methanol, react at room temperature for 2 hours, and confirm that the reaction is complete by thin layer chromatography, After quenching the reaction with 10 parts by weight of 1 mol / L sodium hydrogen sulfide aqueous solution, the reaction solution was concentrated and then added to extract the product with ethyl acetate, the organic phase was retained by liquid separation, and the organic phase was collected after drying with anhydrous sodium sulfate. Evaporation affords product I.

[0038] (2) Add 10 parts by weight of product I to 100 parts by weight of xylene, then add 10 parts by weight of modified monomer II tert-butyl acetoacetate, heat to 130°C for 5 hours, and remove xylene by vacuum distillation. Separated by column chromatography, the eluent is ethyl acetate / petroleum ether or dichloromethane / ethyl acetat...

Embodiment 3

[0045] (1) Mix 10 parts by weight of vanillin, 10 parts by weight of sodium borohydride or sodium cyanoborohydride and 100 parts by weight of methanol, and react at room temperature for 2 hours. After confirming that the reaction is complete by thin layer chromatography, use 10 After quenching the reaction with 1 mol / L sodium hydrosulfide aqueous solution in parts by weight, the reaction solution was concentrated and then added with ethyl acetate to extract the product, the organic phase was retained by liquid separation, and the organic phase was collected after drying with anhydrous sodium sulfate, and obtained by rotary evaporation Product I.

[0046] (2) Add 10 parts by weight of product I to 100 parts by weight of xylene, then add 10 parts by weight of modified monomer II ethyl acetoacetate, heat to 130°C for 5 hours, remove xylene by vacuum distillation, and use Separation by column chromatography, the eluent is ethyl acetate / petroleum ether or dichloromethane / ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com