Anti-yellowing powder coating for architectural decoration

A technology for powder coatings and architectural decoration, applied in the field of coatings, which can solve the problems of easy oxidative degradation of polymers, production of antagonistic effects, and yellowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material methyl 3-hydroxycinnamate: cas:66417-46-7; purchased from Shanghai Shaoyuan Reagent Co., Ltd.;

[0028] Raw material 4-hydroxypiperidine: cas:5382-16-1; purchased from Shanghai Shaoyuan Reagent Co., Ltd.;

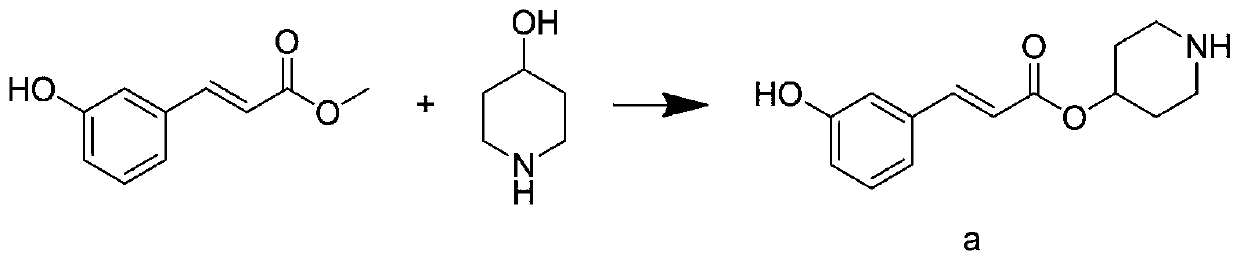

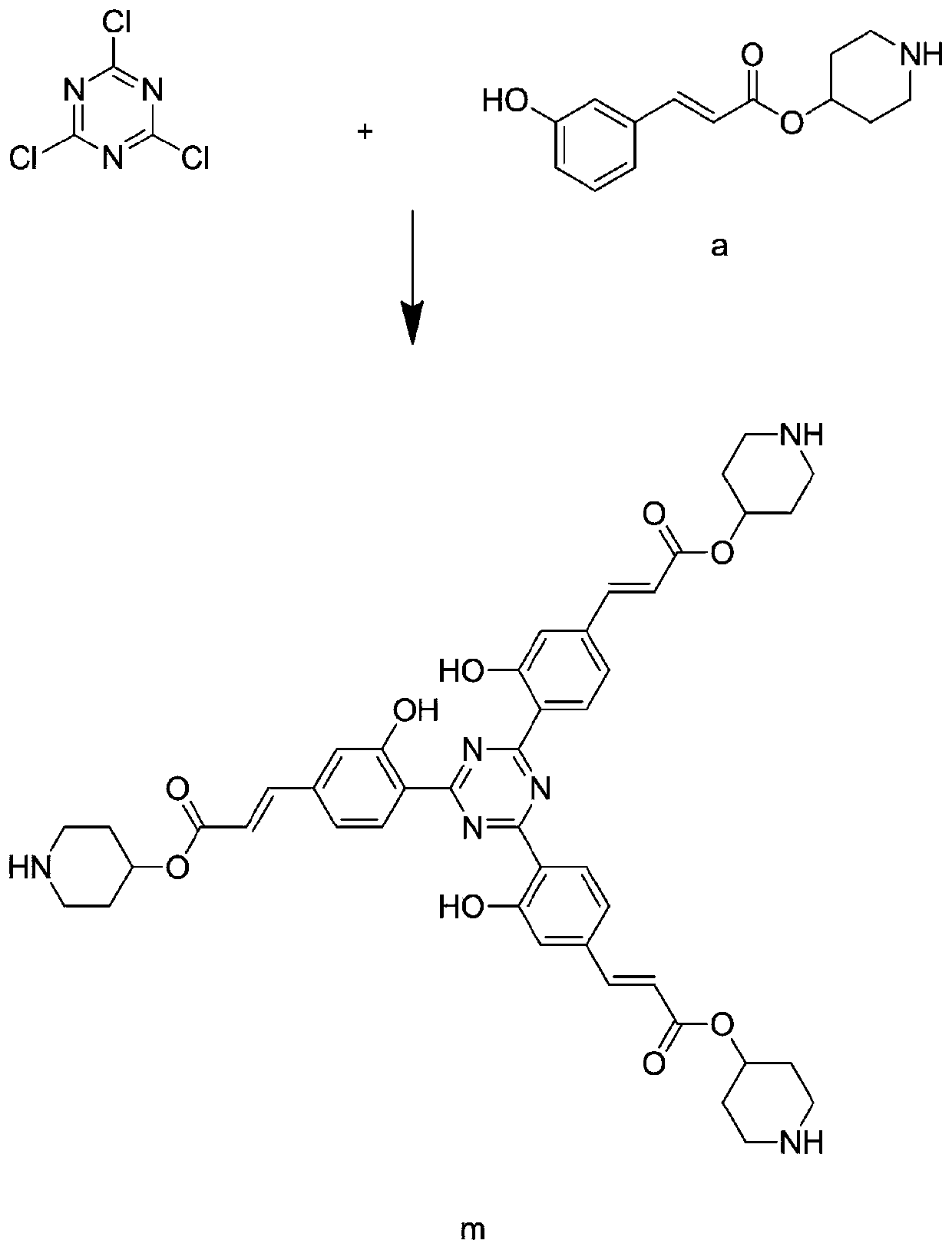

[0029] see Figure 1-2 Shown, the preparation method of anti-yellowing agent specifically comprises the following steps:

[0030] The first step, add 1mol 3-hydroxycinnamate methyl ester, 1.1mol 4-hydroxypiperidine, 12mmol catalyst tin tetrachloride and 4L solvent xylene in the reactor, pass into nitrogen to replace the air in the reactor, while Raise the temperature to 135°C while stirring, keep warm for transesterification reaction for 6 hours, after the reaction is completed, add activated carbon for thermal decolorization for 5 minutes, filter while hot, and use 30% DMF ether solution for recrystallization to obtain raw material a;

[0031] The second step, add 0.1mol cyanuric chloride, 200ml solvent chloroform, 0.3mol anhydrous AlCl in the reactio...

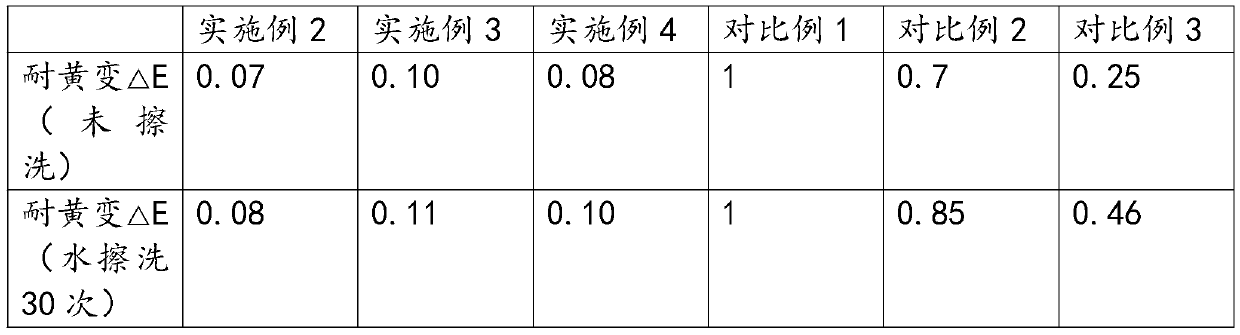

Embodiment 2

[0034] A kind of anti-yellowing powder coating that is used for building decoration, comprises the raw material of following weight: epoxy acrylate resin 75g, mica powder 10g, pigment filler (titanium dioxide) 20g, anti-yellowing agent 3.5g, leveling agent 1g, Precipitated barium sulfate 6g, benzoin 1g.

[0035] The Tg of epoxy acrylate resin is 49°C, the number average molecular weight is 12000, and the epoxy equivalent is 457;

[0036] The leveling agent is powder leveling agent RB505;

[0037] The preparation method of anti-yellowing powder coating is:

[0038] Put the raw materials of each component into a ball mill for grinding and mixing for 10 minutes. After mixing, put them into a twin-screw extruder for extrusion and tabletting. The extrusion temperature is 110°C in the first zone and 130°C in the second zone. The material is crushed and finely crushed, and sieved to obtain a yellowing-resistant powder coating with a particle size of 10-50 microns.

Embodiment 3

[0040] A kind of anti-yellowing powder coating that is used for building decoration, comprises the raw material of following weight: epoxy acrylate resin 65g, mica powder 12g, pigment and filler (titanium dioxide) 15g, anti-yellowing agent 4g, leveling agent 1g, precipitation Barium sulfate 3g, benzoin 2g.

[0041] The Tg of epoxy acrylate resin is 52°C, the number average molecular weight is 13000, and the epoxy equivalent is 512;

[0042] The leveling agent is powder leveling agent RB505;

[0043] The preparation method of anti-yellowing powder coating is:

[0044] Add the raw materials of each component to a ball mill for grinding and mixing for 15 minutes. After mixing, put them into a twin-screw extruder for extrusion and tabletting. The extrusion temperature is 105°C in the first zone and 125°C in the second zone. The material is crushed and finely crushed, and sieved to obtain a yellowing-resistant powder coating with a particle size of 10-50 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com