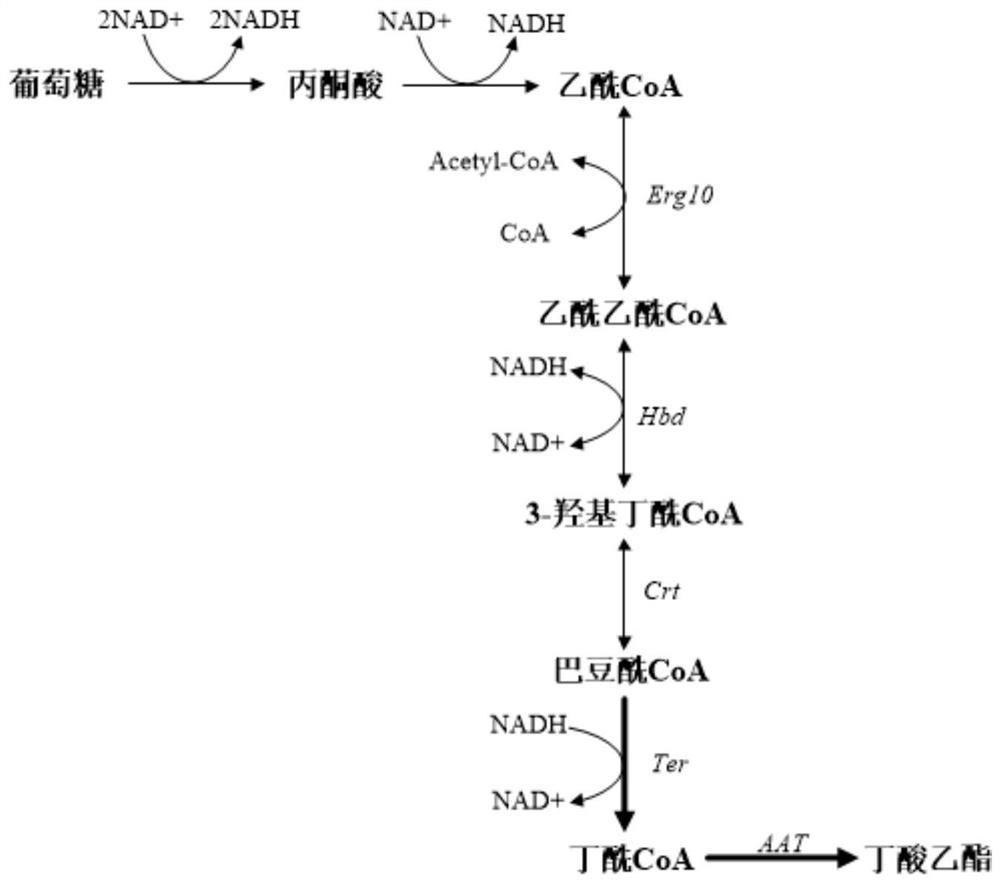

A high-yielding ethyl butyrate-producing Saccharomyces cerevisiae strain and its construction method and use

A technology of Saccharomyces cerevisiae and ethyl butyrate, applied in the field of bioengineering, can solve the problem of not synthesizing ethyl butyrate and the like, and achieve the effects of quality improvement and stability, broad market prospects and important market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: Construction of producing ethyl butyrate Saccharomyces cerevisiae strain

[0073] The starting strain CICC32315 used in this example. The Escherichia coli DH5a was purchased from Takara Company. The YPD medium is a general complete medium, and the solid medium contains 2% (mass percentage) imported agar powder.

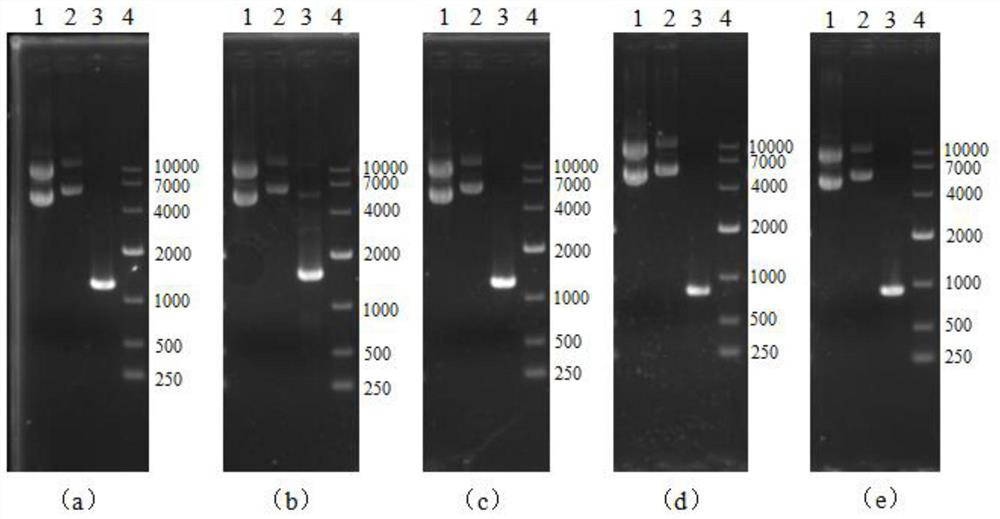

[0074] According to the gene sequences and integrated plasmid sequences in NCBI Genebank, the following primers were designed, as shown in Table 1.

[0075] Table 1 Primers

[0076]

[0077]

[0078] The PCR amplification system used in this example is shown in Table 2.

[0079] Table 2 PCR amplification system

[0080]

[0081] The main construction process of the strain is as follows:

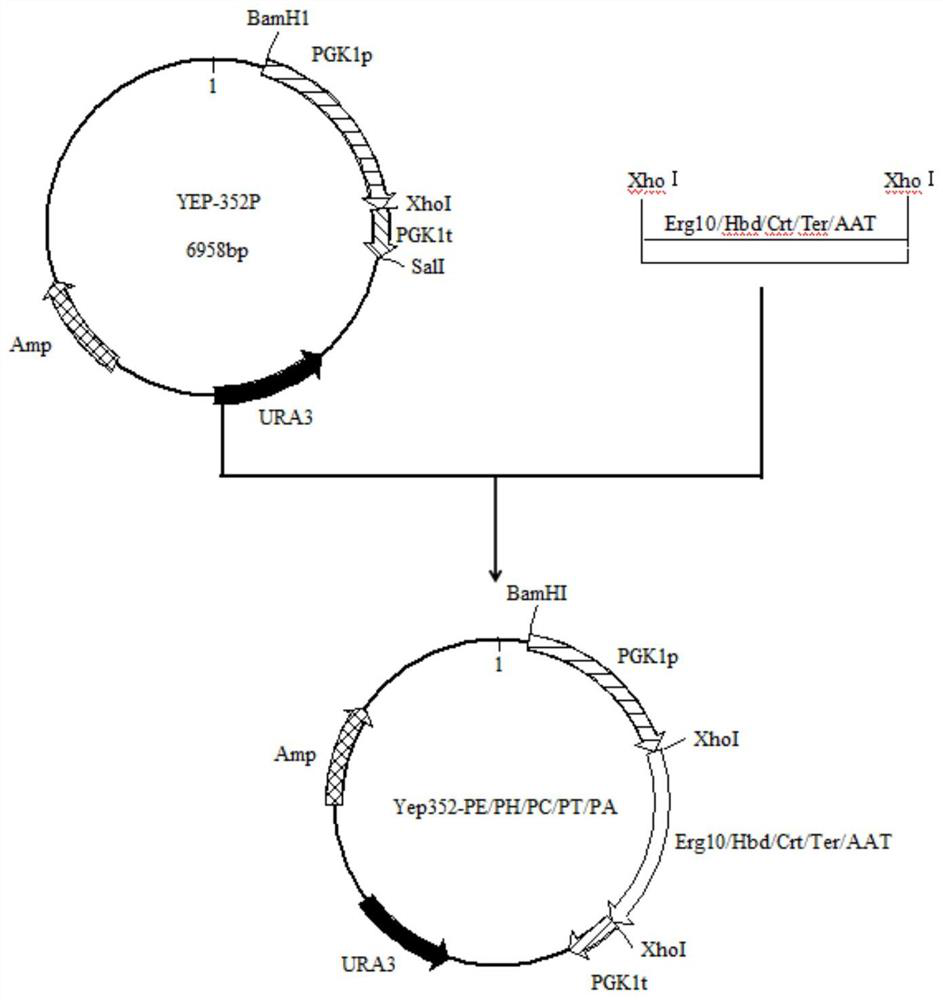

[0082] (1) Construction of Yep352-PE / PH / PC / PT / PA plasmid

[0083] Using Yep352-P as the basic plasmid, construct recombinant plasmids carrying genes Erg10, Hbd, Crt, Ter, AAT, referred to as recombinant plasmids Yep352-PE, Yep352-PH, Yep352-PC, Yep...

Embodiment 2

[0110] Example 2: Corn raw material thick mash fermentation experiment of the starting strain and the modified strain

[0111] (1) Corn mash fermentation experiment of recombinant strains EST, EDT, EDS and EDST and parental strain (AY14-ɑ)

[0112]The parental strain AY14-ɑ and the recombinant strains EST, EDT, EDS and EDST were subjected to corn mash fermentation experiments at the same time. The fermentation process roadmap: corn flour→soaking→liquefaction→saccharification→cooling→inoculation→fermentation→steaming→determination index;

[0113] Pick a ring of yeast cells, put them into test tubes containing 5mL of primary seed medium, culture at 30°C for 24 hours, and inoculate 10% of the inoculum into a 150mL Erlenmeyer flask containing 45mL of secondary seed medium , static culture at 30°C for 16h to the late logarithmic phase, inoculate the fermentation medium with 10% inoculum amount, and statically ferment at 30°C. Weigh once every 12 hours, and when the two weight los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com