Foamed nickel substrate loaded copper cobaltate nanowire array material and preparation method thereof

A nanowire array, substrate-loaded technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of particle aggregation, cycle performance degradation, and material morphology is not uniform and regular, and achieves simple equipment and production. Low cost and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

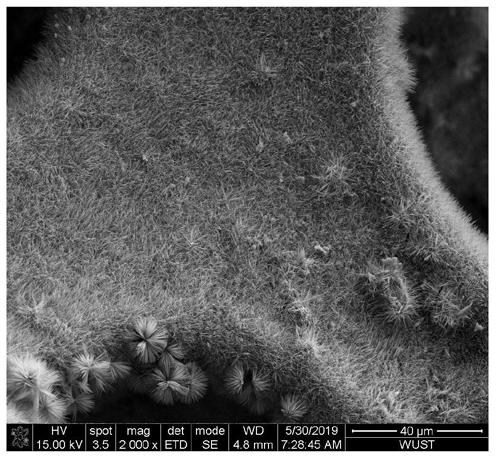

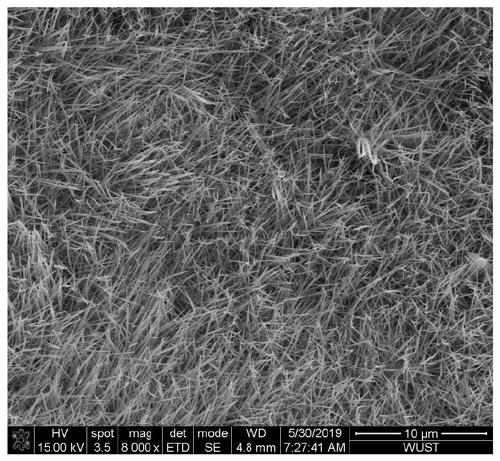

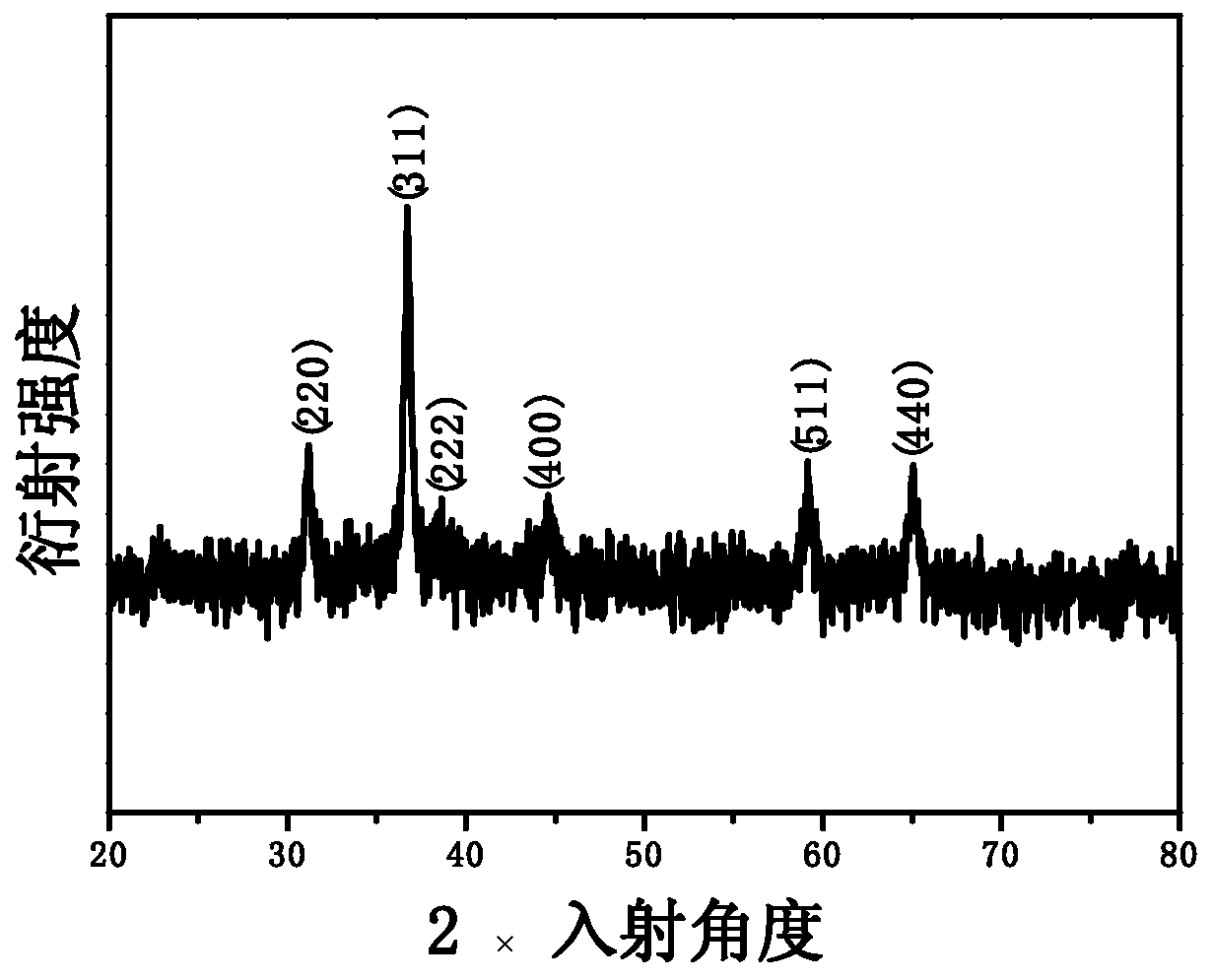

[0038] A nickel foam substrate supported copper cobalt oxide nanowire array material and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0039] Step 1, press cupric chloride dihydrate: cobalt chloride hexahydrate: the mol ratio of urea is 3: 6: 28 batching, then be 0.012mol / L by the concentration of cupric chloride dihydrate, the dihydrate chloride Copper, the cobalt chloride hexahydrate and the urea are dissolved in deionized water and stirred at room temperature to obtain a mixed solution.

[0040] Step 2. Transfer the mixed solution into a high-pressure reactor, then immerse the pretreated nickel foam into the mixed solution, perform a hydrothermal reaction at 120°C for 10 hours, cool naturally to room temperature, and then use deionized water to Washed 4 times, dried at 85° C. for 7 hours to obtain the precursor.

[0041] Step 3. Place the precursor in a tube-type atmosphere furnace, in an air atmosphere, rai...

Embodiment 2

[0046] A nickel foam substrate supported copper cobalt oxide nanowire array material and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0047] Step 1, press cupric chloride dihydrate: cobalt chloride hexahydrate: the mol ratio of urea is 3: 6: 28 batching, then be 0.006mol / L by the concentration of cupric chloride dihydrate, the described dihydrate chloride Copper, the cobalt chloride hexahydrate and the urea are dissolved in deionized water and stirred at room temperature to obtain a mixed solution.

[0048] Step 2. Transfer the mixed solution into a high-pressure reactor, then immerse the pretreated nickel foam into the mixed solution, perform a hydrothermal reaction at 125°C for 12 hours, cool naturally to room temperature, and then use deionized water to Washed three times and dried at 80°C for 8 hours to obtain the precursor.

[0049] Step 3. Place the precursor in a tubular atmosphere furnace, in an air at...

Embodiment 3

[0053] A nickel foam substrate supported copper cobalt oxide nanowire array material and a preparation method thereof. The specific steps of the preparation method described in this embodiment are:

[0054] Step 1, press cupric chloride dihydrate: cobalt chloride hexahydrate: the mol ratio of urea is 3: 6: 28 batching, then be 0.009mol / L by the concentration of cupric chloride dihydrate, the dihydrate chloride Copper, the cobalt chloride hexahydrate and the urea are dissolved in deionized water and stirred at room temperature to obtain a mixed solution.

[0055] Step 2. Transfer the mixed solution into a high-pressure reactor, then immerse the pretreated nickel foam into the mixed solution, perform a hydrothermal reaction at 123°C for 11 hours, cool naturally to room temperature, and then use deionized water to Washed three times and dried at 85°C for 7 hours to obtain the precursor.

[0056] Step 3. Put the precursor in a tube-type atmosphere furnace, in the air atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com