Self-cleaning intraocular lens and preparation method thereof

An intraocular lens and self-cleaning technology, applied in intraocular lenses, prostheses, medical science, etc., can solve problems such as easy adhesion of proteins and cells, aggravate the proliferation of inflammatory reactions, affect the visual quality of patients, and achieve enhanced adhesion , prevention of complications, and maintenance of optical clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of self-cleaning intraocular lens, its concrete steps are:

[0040] (1) Soak the hydrophobic acrylate intraocular lens in sterile double-distilled water and ultrasonically clean it for 5-10 minutes, and then wash it with N 2 Stream dry.

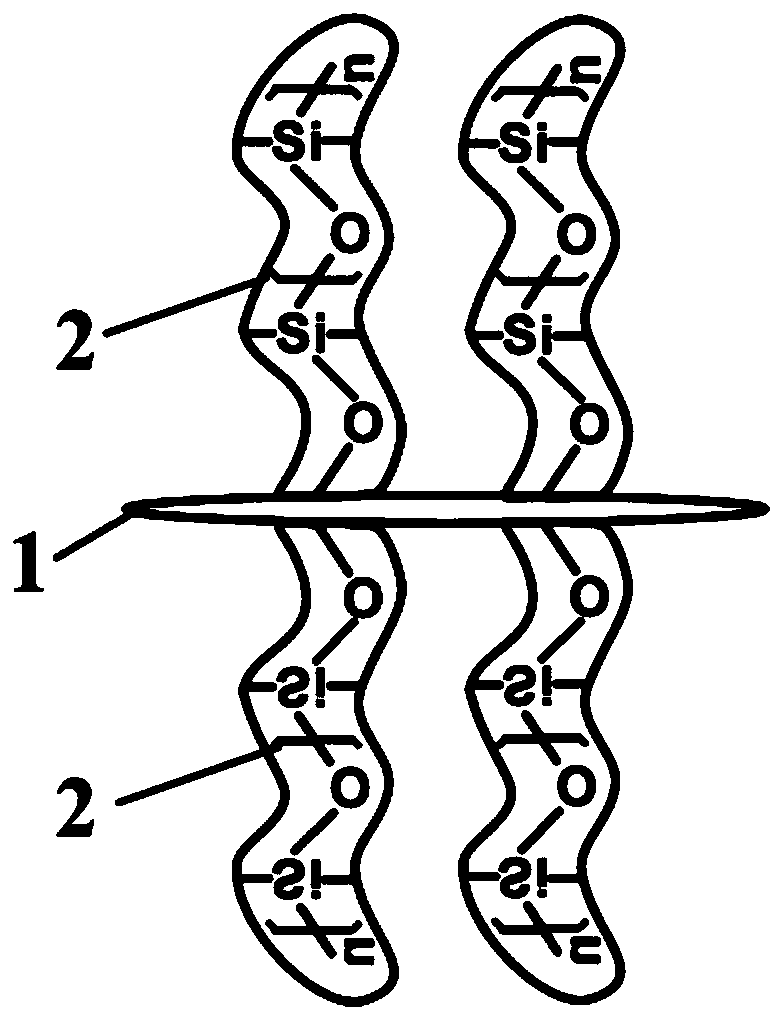

[0041] (2) Put the intraocular lens into the chemical vapor deposition reaction chamber, vaporize the PDMS stock solution into the reaction chamber under vacuum conditions, and heat to 100° C. for 24 hours to react.

[0042] (3) After the reaction, the PDMS-modified intraocular lens was taken out and cooled to room temperature.

[0043] (4) The intraocular lens is sterilized with ethylene oxide and sealed for storage.

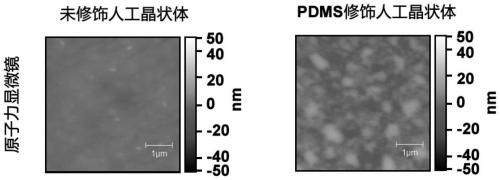

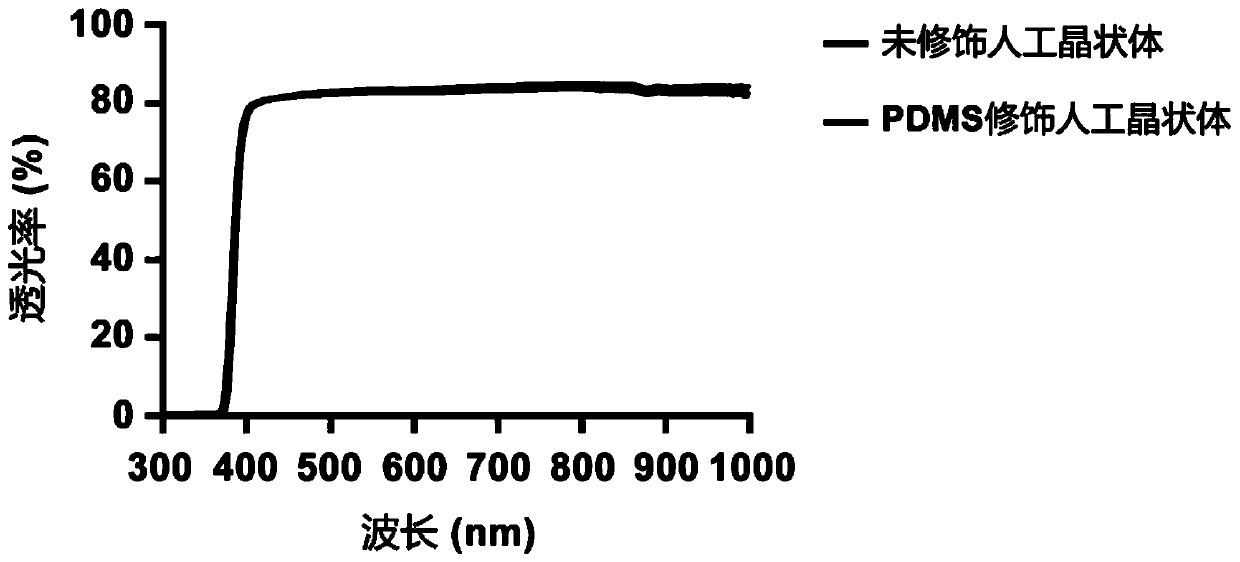

[0044] Such as Figure 1 to Figure 4 As shown, the intraocular lens prepared by this method has a surface roughness value of 1.316nm detected by an atomic force microscope; the static contact angle value of deionized water on the surface of the intraocular lens detected by a static contact ...

Embodiment 2

[0046] A kind of preparation method of self-cleaning intraocular lens, its concrete steps are:

[0047] (1) Soak the hydrophobic acrylate intraocular lens in sterile double-distilled water for 5-10 minutes and ultrasonically clean it, and then dry it with N2 flow;

[0048] (2) The intraocular lens is fixed on the sample stage of the plasma cleaning machine, and O 2 The oxygen ion beam is formed to impact the surface of the intraocular lens to generate free radicals, the power is 60W, and the action time is 30s; the intraocular lens is placed in the chemical vapor deposition reaction chamber, and the PDMS stock solution is vaporized and sent into the reaction chamber under vacuum conditions. Heating to 100°C for 24 hours;

[0049] (3) After the reaction, the PDMS-modified intraocular lens was taken out and cooled to room temperature;

[0050] (4) The intraocular lens is sterilized with ethylene oxide and sealed for storage.

[0051] The intraocular lens prepared by this meth...

Embodiment 3

[0054] A kind of preparation method of self-cleaning intraocular lens, its concrete steps are:

[0055] (1) Soak the hydrophobic acrylate intraocular lens in sterile double-distilled water for 5-10 minutes and ultrasonically clean it, and then dry it with N2 flow;

[0056] (2) The intraocular lens is fixed on the sample stage of the plasma cleaning machine, and O 2 Form an oxygen ion beam to impact the surface of the intraocular lens to generate free radicals, the power is 60W, and the action time is 120s; then the intraocular lens is placed in the chemical vapor deposition reaction chamber, and the PDMS stock solution is vaporized and sent into the reaction chamber under vacuum conditions , heated to 100°C for 24 hours;

[0057] (3) After the reaction, the PDMS-modified intraocular lens was taken out and cooled to room temperature;

[0058] (4) The intraocular lens is sterilized with ethylene oxide and sealed for storage.

[0059] The intraocular lens prepared by this meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness value | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com