Polyimide/surface-modified metal organic framework mixed matrix membrane as well as preparation method and application thereof

A technology of metal-organic framework and mixed matrix membrane, which is applied in the direction of separation methods, non-metallic elements, chemical instruments and methods, etc., can solve problems such as the compatibility of mixed matrix membranes, improve interfacial compatibility, and solve interfacial phase problems. Capacitive, simple and controllable effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of a polyimide / surface-modified metal organic framework mixed matrix film according to an embodiment of the present invention includes the following steps:

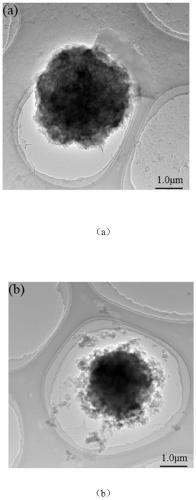

[0038] (1) In order to make the interface compatibility between the MOF and the polymer matrix better, dopamine is used to modify the surface of the MOF.

[0039] It specifically includes: adding MOF nanoparticles to a buffer with a pH value of 7.5 to 9.0, the concentration of MOF in the buffer is 0.4 to 0.6 mg / mL, ultrasound for 30 to 90 minutes, and magnetic stirring for 12 to 36 hours to make the dispersion evenly Suspension; then add dopamine to the above suspension, ultrasonic for 15~45min, magnetic stirring for 3~18h; centrifugation, washing with deionized water to neutrality, vacuum drying at 40~80℃ for 24h.

[0040] (2) Add the surface modified MOF to the organic solvent X, ultrasonic and magnetic stirring to make the dispersion uniform; add the polyimide film material, continue ultrasonic a...

Embodiment 1

[0051] The polyimide / surface-modified MOF mixed matrix film prepared in the embodiment of the present invention uses self-made polyimide as the polymer matrix, and the surface-modified AlFu MOF is added to the polymer matrix, wherein, The mass ratio of polyimide to AlFu MOF is 1:0.020. The preparation process of the mixed matrix film is as follows:

[0052] (1) Preparation of polyimide polymer matrix:

[0053] Under the protection of nitrogen, 0.64mmol of homemade diaminodibenzo-18-crown-6 and 1.92mmol of commercial 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane are used as aromatic Diamine monomer is added to 9.2mL N,N-dimethylacetamide, and the diamine solution is obtained after magnetic stirring is completely dissolved; according to the molar ratio of aromatic diamine to aromatic dianhydride of 1:1, 2.56mmol of 4,4'-hexafluoroisopropyl phthalic anhydride solid was directly added to the diamine solution, and stirred at room temperature for 24 hours for solution polycondensat...

Embodiment 2

[0062] Preparation of polyimide / surface modified MOF mixed matrix film. The mixed matrix film uses self-made polyimide as a polymer matrix, and surface-modified AlFu MOF is added to the polymer matrix, wherein the mass ratio of polyimide to AlFu MOF is 1:0.053.

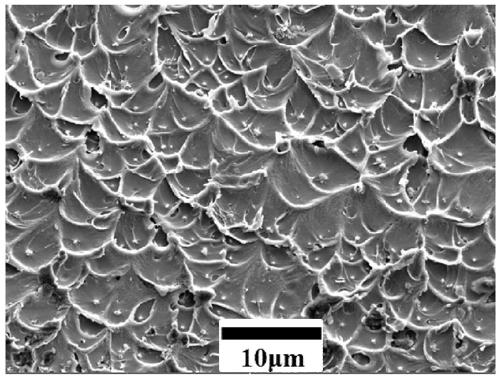

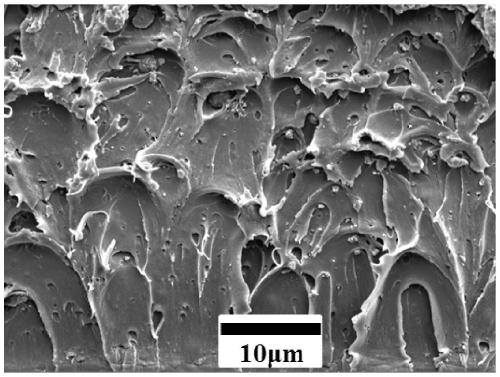

[0063] image 3 It is a scanning electron micrograph of a cross-section of a mixed matrix film made with surface-modified AlFu MOF.

[0064] Under the conditions of 35℃ and 2.0MPa, the polyimide / surface modified MOF mixed matrix film is used for CO 2 / N 2 The separation of mixed gas (20 / 80vol%), its CO 2 Permeability coefficient is 171barrer, CO 2 / N 2 The selectivity is 81; at the same time the mixed matrix membrane is used for CO 2 / CH 4 The separation of mixed gas (10 / 90vol%), its CO 2 Permeability coefficient is 162barrer, CO 2 / N 2 The selectivity is 80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com