Mesoporous silica-supported tungsten-promoted nickel-based catalyst for autothermal reforming of acetic acid for hydrogen production

A technology of mesoporous silica and nickel-based catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogen, etc., can solve the problems of catalyst deactivation, poor thermal stability of catalyst structures, etc. , to achieve the effect of promoting acetic acid dehydrogenation, inhibiting acetic acid dehydration and ketoneation reactions, and improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Take by weighing 10.930g of cetyltrimethylammonium bromide (CTAB), be dissolved in the mixed solution of 200g ethanol, 200g deionized water and 18.700g strong ammonia water, obtain transparent solution, and under vigorous stirring condition, 20.833 g of tetraethoxysilane (TEOS) was slowly dropped into the mixed solution, maintained vigorous stirring for 2 hours, and then filtered under reduced pressure to obtain a white precipitate, washed with deionized water until neutral, and dried at 110°C 12 hours, baked in air at 550°C for 6 hours to obtain SiO 2 Carrier; 2.350g Ni(NO 3 ) 2 ·6H 2 O was dissolved in deionized water and SiO was added 2 Carrier, impregnated for 0.5 hours, stirred and evaporated to dryness in a water bath at 80°C, dried at 110°C for 12 hours, and roasted at 550°C in air for 8 hours to obtain a CDUT-NS-1 catalyst. The weight percentage of the catalyst is composed of: Nickel (NiO) is 10.0%, silicon dioxide (SiO 2 ) is 90.0%.

[0026] The reactivit...

example 2

[0029] Take by weighing 10.930g of cetyltrimethylammonium bromide (CTAB), be dissolved in the mixed solution of 200g ethanol, 200g deionized water and 18.700g strong ammonia water, obtain transparent solution, and under vigorous stirring condition, 20.833 g of tetraethoxysilane (TEOS) was slowly dropped into the mixed solution, maintained vigorous stirring for 2 hours, and then filtered under reduced pressure to obtain a white precipitate, washed with deionized water until neutral, and dried at 110°C 12 hours, baked in air at 550°C for 6 hours to obtain SiO 2 Carrier; 7.930g of (NH 4 ) 10 h 2 (W 2 o 7 ) 6 Dissolve in deionized water, add SiO 2 Carrier, impregnated for 0.5 hours, stirred and evaporated to dryness in a water bath at 80°C, dried at 110°C for 12 hours, and roasted at 550°C in air for 8 hours to obtain a CDUT-WS-1 catalyst. The weight percentage of the catalyst is composed of: Tungsten (WO 3 ) is 10.0%, silicon dioxide (SiO 2 ) is 90.0%.

[0030] Catalyst...

Embodiment 1

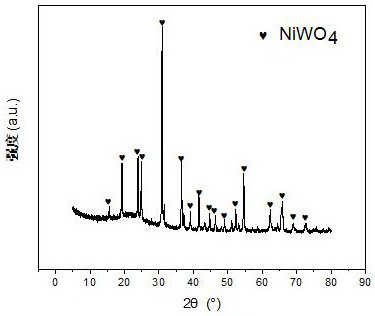

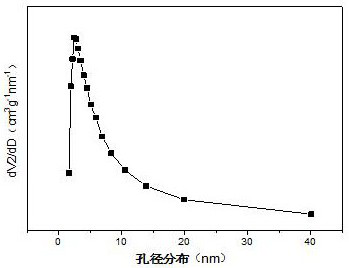

[0032] Take by weighing 10.930g of cetyltrimethylammonium bromide (CTAB), be dissolved in the mixed solution of 200g ethanol, 200g deionized water and 18.700g strong ammonia water, obtain transparent solution, and under vigorous stirring condition, 20.833 g of tetraethoxysilane (TEOS) was slowly dropped into the mixed solution, maintained vigorous stirring for 2 hours, and then filtered under reduced pressure to obtain a white precipitate, washed with deionized water until neutral, and dried at 110°C 12 hours, baked in air at 550°C for 6 hours to obtain SiO 2 Carrier; 1.601g of (NH 4 ) 10 h 2 (W 2 o 7 ) 6 and 2.420g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in deionized water and SiO was added 2 The carrier was soaked for 0.5 hours, stirred and evaporated to dryness in a water bath at 80°C, dried at 110°C for 12 hours, and roasted at 550°C in air for 8 hours to obtain the attached figure 1 The structure shown, that is, containing monoclinic NiWO 4 supported on mesoporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com