Graphene-doped nickel cobalt lithium manganate composite positive electrode material and preparation method thereof

A composite cathode material, nickel-cobalt-lithium manganese oxide technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problem of not effectively reducing the side reactions of ternary materials and electrolytes, reducing the energy density and processing performance of materials, and lacking Ternary material protection and other issues to achieve good cycle performance, improve electrical conductivity, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Prepare 1 mol / L mixed metal ion salt solution A of nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio of nickel, cobalt, and manganese elements of 5:2:3, 1 L. Configure 6mol / L precipitant sodium hydroxide solution B, 1L. Prepare 3mol / L complexing agent ammonia solution C, 1L. Prepare 0.2L of mixed solution D of 1mol / L sodium hydroxide and 1mol / L ammonia water.

[0050] Neutralize the 0.5wt% graphene oxide solution G1 with sodium hydroxide to a pH of 10-11, then add dopamine hydrochloride according to the ratio of graphene oxide:dopamine hydrochloride = 10:1, and stir for 30 minutes at 4000rpm to obtain solution E .

[0051] Add 0.2L of solution D to the co-precipitation tank at one time, and under the protection of nitrogen atmosphere, add solution A, solution B and solution C to the coprecipitation tank at the same time at a rate of 0.01 L / min. Adjust the stirring speed to 200 rpm and the reaction temperature to 55°C. After dropping ...

Embodiment 2-6、 comparative example 1-5

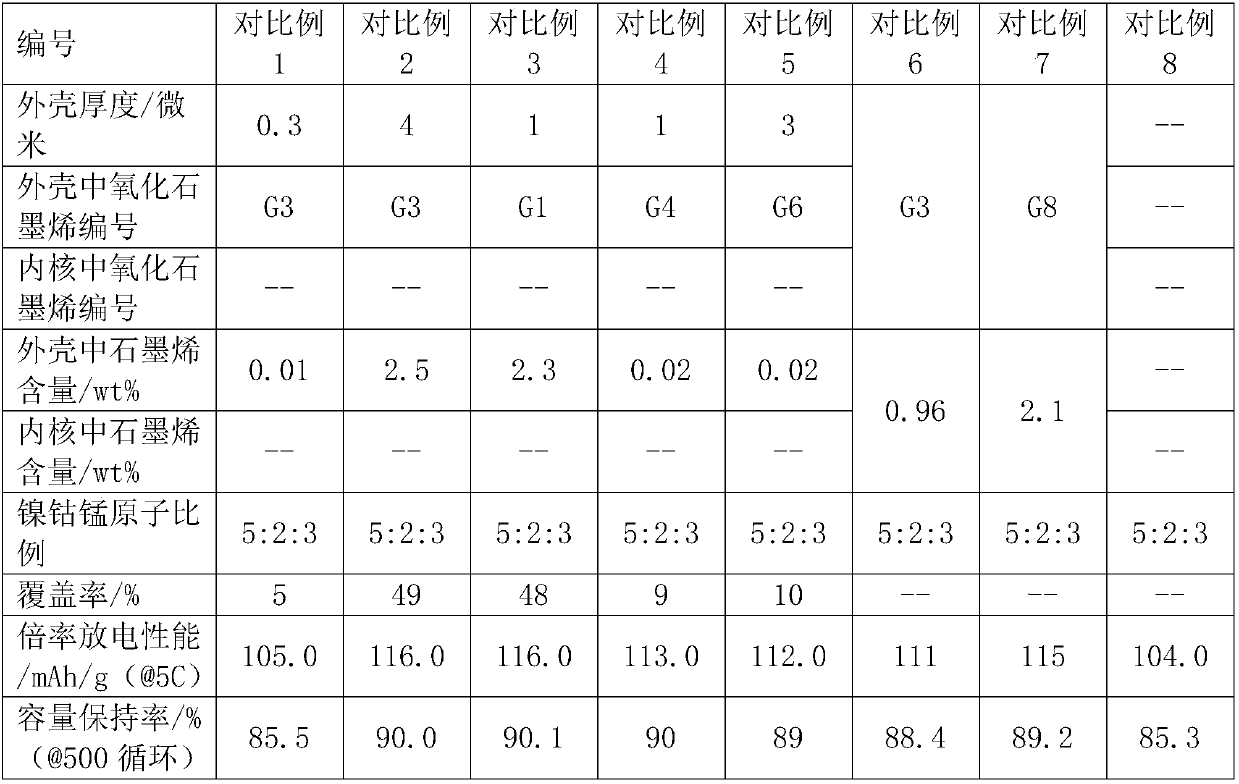

[0054] Appropriately replace the graphene oxide solution G2-G6, adjust the concentration and volume of the solutions A, B, C, D, E, the time of addition, the rate of addition, the stirring speed, the temperature of reaction, and carry out the operation similar to that of Example 1 to obtain The graphene-doped nickel-cobalt-lithium manganate composite positive electrode material of Examples 2-6 and Comparative Examples 1-5 shown in Table 2-3.

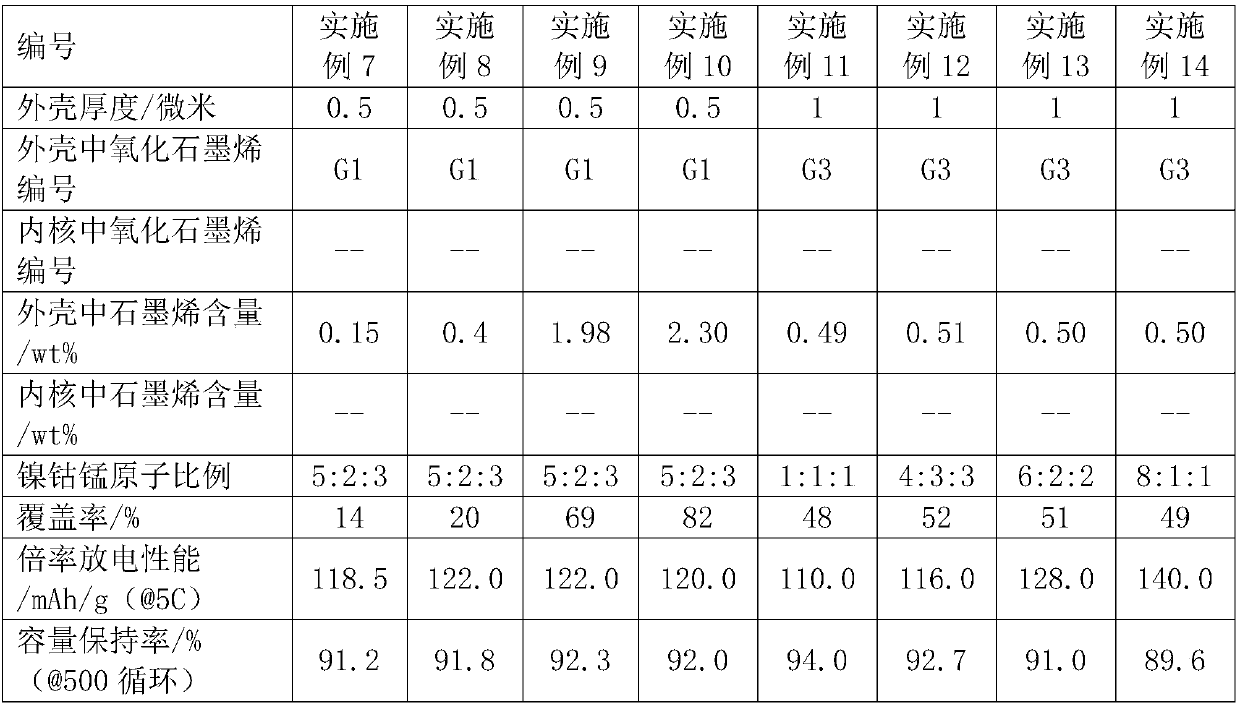

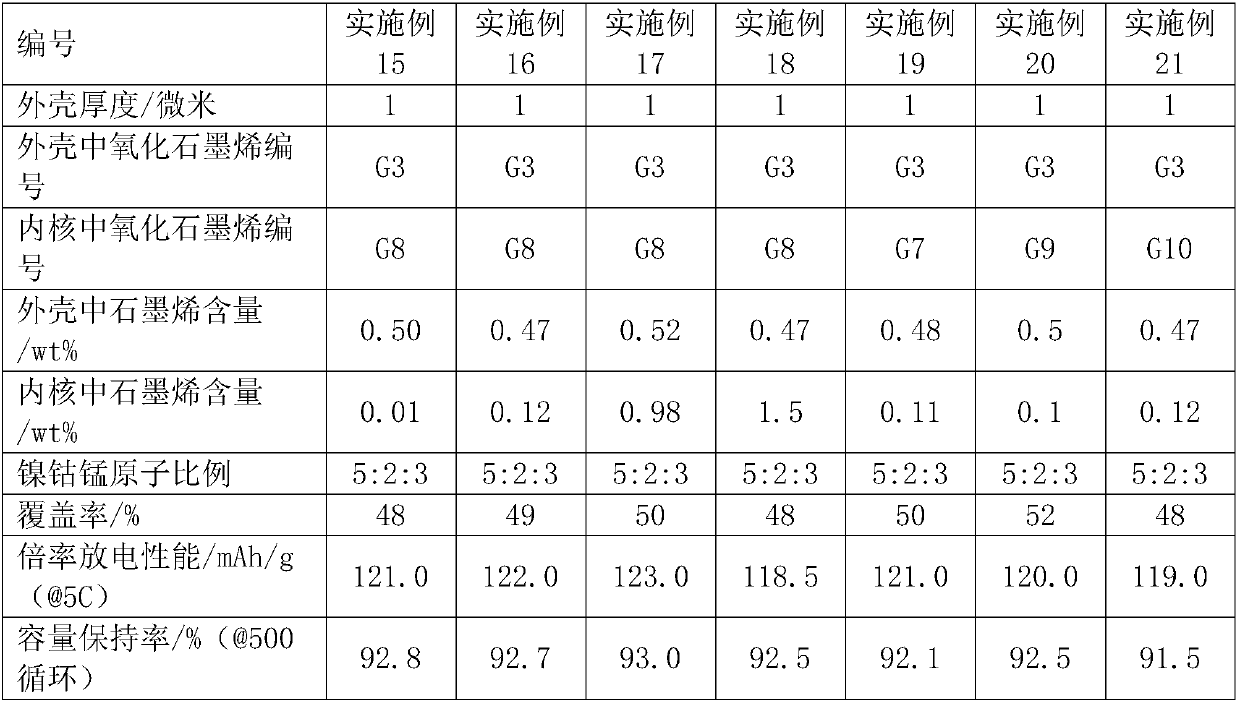

Embodiment 7-14

[0071] Appropriately change the type of graphene oxide solution, adjust the atomic ratio of nickel-cobalt-manganese, the concentration and volume of solutions A, B, C, D, E, the time of addition, the rate of addition, the stirring speed, the reaction temperature, and perform steps similar to those in Example 1 According to the operation, the graphene-doped nickel-cobalt-lithium-manganese-oxide composite cathode material of Examples 7-14 as shown in Table 4 was obtained.

[0072] Table 4

[0073]

[0074] As shown in the above Tables 2 and 4, according to Examples 1 and 7-10, it can be seen that by adjusting the content of graphene in the nickel-cobalt-lithium-manganese-oxide shell, nickel-cobalt-lithium-manganate composite cathode materials with different graphene coverages can be prepared. Although the prepared nickel-cobalt-lithium manganese oxide composite cathode materials have good rate and cycle performance, when the coverage of graphene on the shell is more than 20% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com