Preparation method of carbon-supported Pt/M heterostructure nanowire electrocatalyst and an application

A heterogeneous structure, rice wire technology, applied in nanotechnology, structural parts, circuits, etc., to achieve high length/diameter ratio, increase the number of attachment sites, and facilitate large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of Pt / NiO heterostructure nanowires

[0041] Disperse platinum acetylacetonate (15.0mg), nickel acetylacetonate (10.0mg) and hexadecyltrimethylammonium bromide (60.0mg) in oleylamine (4.5ml) / oleic acid (0.5ml) and sonicate for 20min ; Add molybdenum carbonyl (15mg), and then ultrasonic 20min; at 25 ℃, CO atmosphere, replace the air in the reaction system for 20min; raise the temperature and maintain 3h at 180 ℃; cool to room temperature, centrifugal washing, dispersed in cyclohexane ( 2ml) for use.

[0042] (2) Preparation of carbon-supported Pt / NiO heterostructure nanowire electrocatalysts

[0043] Disperse activated carbon (50mg) in ethanol (5ml) / cyclohexane (5ml), and sonicate for 30min to obtain a suspension; add dispersed Pt / NiO heterostructure nanowires (2ml), and sonicate for 30min; centrifuge, wash and dry A carbon-supported Pt / NiO heterostructure nanowire electrocatalyst was obtained.

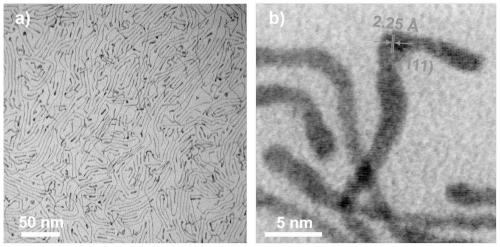

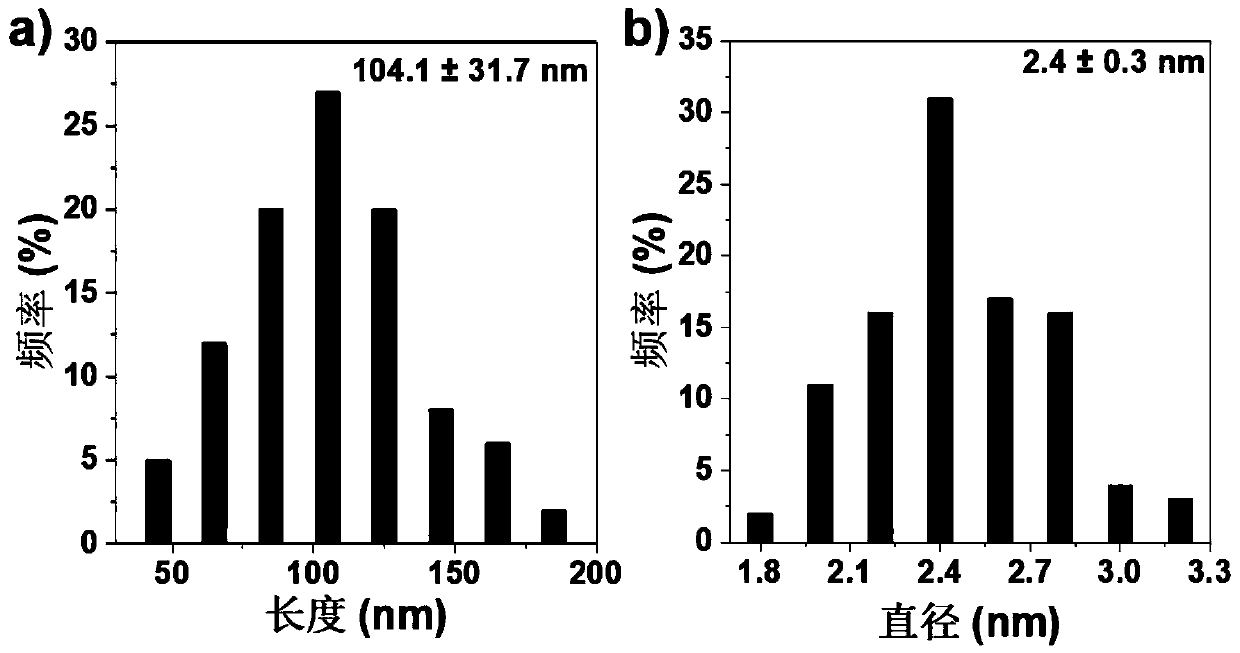

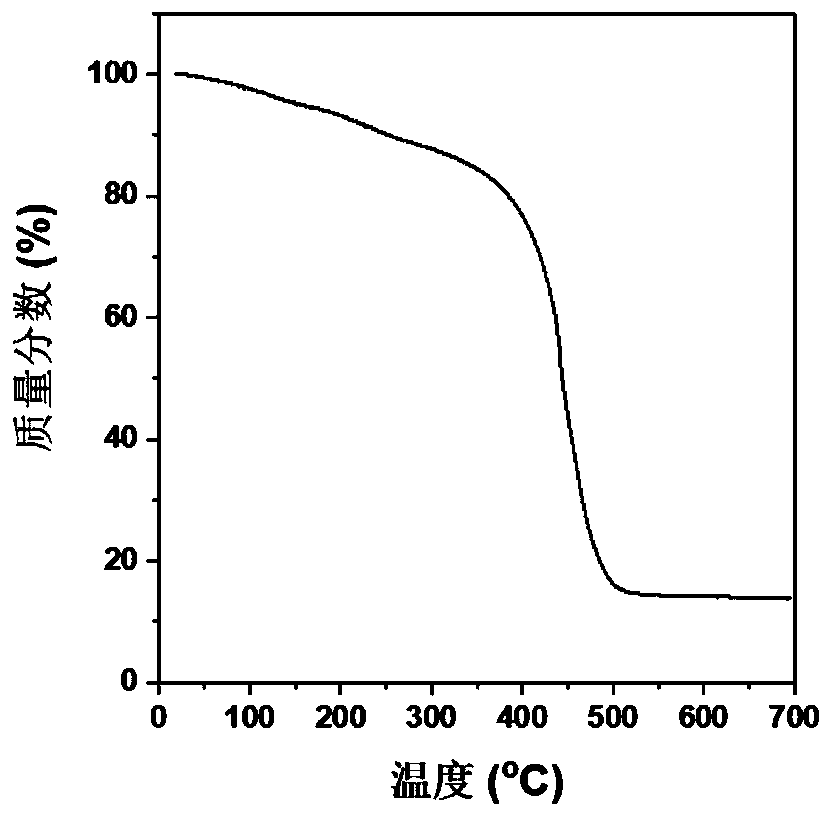

[0044] like figure 1 , TEM results show that the produc...

Embodiment 2

[0050] (1) Preparation of Pt / NiO heterostructure nanowires

[0051] Disperse platinum acetylacetonate (50.0mg), nickel acetylacetonate (30.0mg) and dioctadecyldimethylamine bromide (150.0mg) in oleylamine (15.0ml), sonicate for 30min; add molybdenum carbonyl (90mg ), then ultrasonic for 20min; at 25℃, N 2 Under the atmosphere, the air in the reaction system was replaced for 30 minutes; the temperature was increased and maintained at 185° C. for 2 hours; cooled to room temperature, washed by centrifugation, and dispersed in cyclohexane (6 ml) for use.

[0052] (2) Preparation of carbon-supported Pt / NiO heterostructure nanowire electrocatalysts

[0053] Disperse activated carbon (15mg) in acetone (5ml) / cyclohexane (3ml), and sonicate for 30min to obtain a suspension; add dispersed Pt / NiO heterostructure nanowires (6ml), and sonicate for 30min; centrifuge, wash and dry A carbon-supported Pt / NiO heterostructure nanowire electrocatalyst was obtained.

[0054] like Image 6 , TE...

Embodiment 3

[0059] (1) Preparation of Pt / CuO heterostructure nanowires

[0060] Disperse platinum acetylacetonate (10.0mg), copper acetylacetonate (10.0mg) and didodecyldimethylamine bromide (90.0mg) in oleylamine (5.0ml), sonicate for 30min; add tungsten carbonyl (90mg ), then ultrasonic for 30min; at 25℃, N 2 Under the atmosphere, the air in the reaction system was replaced for 30 minutes; the temperature was increased and maintained at 185° C. for 2 hours; cooled to room temperature, washed by centrifugation, and dispersed in toluene (2 ml) for later use.

[0061] (2) Preparation of carbon-supported Pt / CuO heterostructure nanowire electrocatalysts

[0062] Disperse activated carbon (45mg) in acetone (4ml) / toluene (5ml), and sonicate for 30min to obtain a suspension; add dispersed Pt / CuO heterostructure nanowires (2ml), and sonicate for 30min; centrifuge, wash and dry to obtain carbon Supported Pt / CuO heterostructure nanowire electrocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com