Catalyst for catalytic combustion of chlorine-containing volatile organic gas, and preparation method thereof

An organic gas, catalytic combustion technology, used in catalyst activation/preparation, combustion methods, physical/chemical process catalysts, etc., can solve the problems of loss of active components, affecting catalyst activity and service life, catalyst poisoning, etc. performance, reduce the probability of generating chloride salts, and improve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

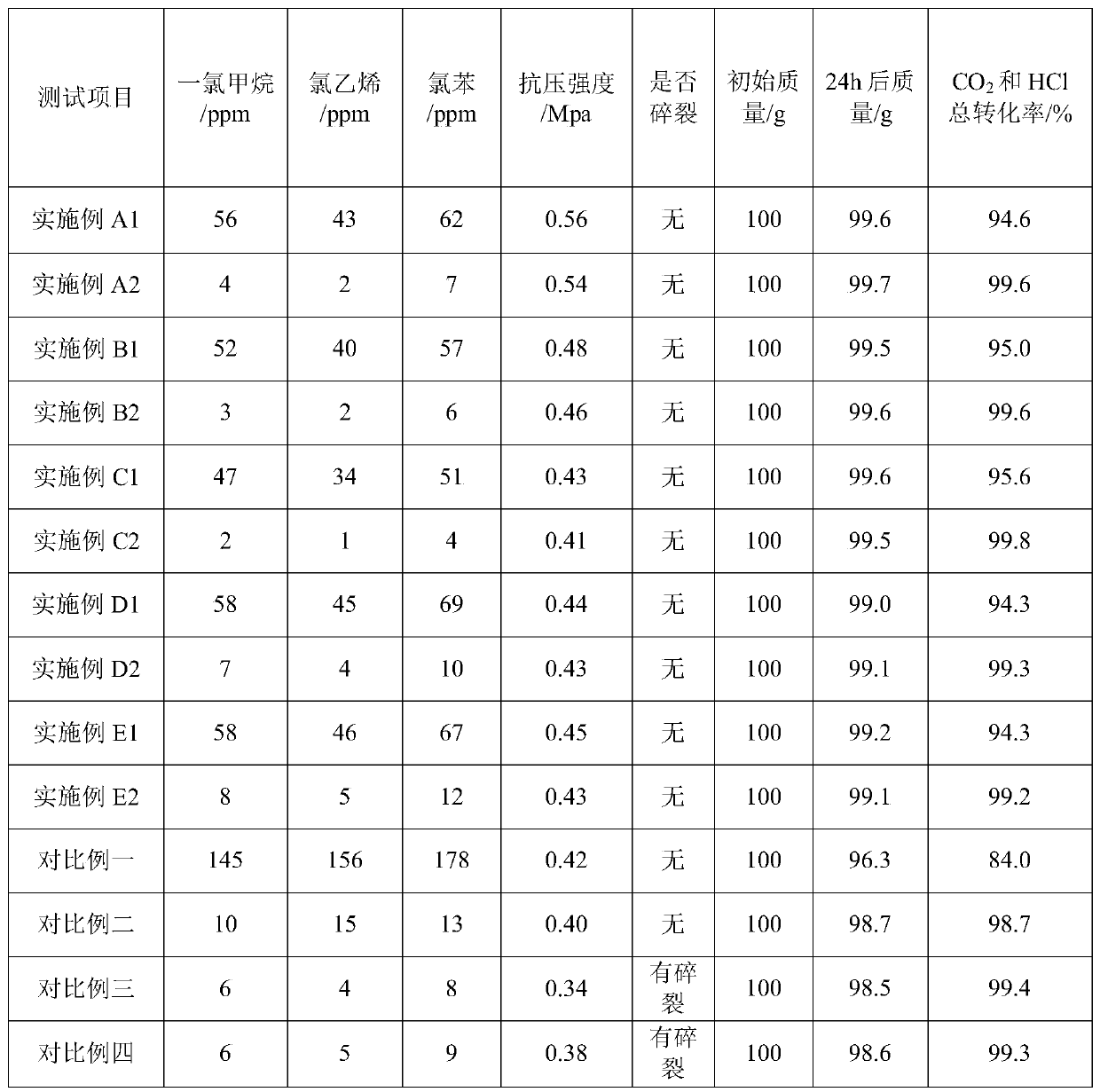

Examples

Embodiment A1

[0037] Step one: dissolve 101.37g of Ti(SO in 10wt% dilute sulfuric acid 4 ) 2 To obtain solution A, dissolve 143.04g of tetraethyl orthosilicate in absolute ethanol to obtain solution B; the solute concentrations in solution A and solution B are both 0.1mol / L, and solution A is added dropwise to solution B to form a mixed solution C;

[0038] Step 2: Slowly add 20% ammonia water dropwise to the mixed solution C until the pH of the solution is 9-13 and a precipitate is formed. After the precipitate is filtered out, rinse it repeatedly with deionized water, and use a vacuum pump at -0.1MPa negative pressure at the same time Suction filtration was carried out until the supernatant liquid obtained after suction filtration was mixed with Ba(NO 3 ) 2 Detect that there is no residual SO4 in the washing liquid 2- Until the filter cake D is obtained, the filter cake D is placed in a drying oven and dried at 110°C for 24 hours;

[0039] Step 3: Take by weighing 32.79g of Ce(NO 3 ...

Embodiment A2

[0043] The difference between this embodiment and embodiment A1 is that the tetraethyl orthosilicate selected is 133.50g, Ti(SO 4 ) 2 It is 94.61g. In addition, step six: take 19.42g of Co (N0 3 ) 2 ·6H 2 O and C 6 h 8 o 7 ·H 2 O is dissolved in deionized water to form a 0.1mol / L solution G;

[0044] Step 7: Immerse the corresponding quality catalyst M-Ce-O / TiO prepared in step 5 into the solution G 2 -SiO 2 , using 100~200uW / cm 2 UV irradiation, aging in helium environment for 12h, drying overnight at 110°C, and then placing the aged raw material in a muffle furnace, the temperature of the muffle furnace is raised from room temperature to 200°C at 2°C / min, and kept for 30min , and then heated up to 500°C at 10°C / min, and calcined at 500°C for 3 hours to prepare the catalyst Co / La-Ce-O / TiO 2 -SiO 2 .

Embodiment B1

[0046] Step one: dissolve 97.62g of Ti(SO in 10wt% dilute sulfuric acid 4 ) 2 To obtain solution A, dissolve 112.70 g of tetraethyl orthosilicate in absolute ethanol to obtain solution B; the solute concentrations in solution A and solution B are both 0.1mol / L, and solution A is added dropwise to solution B to form a mixed solution C;

[0047] Step 2: Slowly add 20% ammonia water dropwise to the mixed solution C until the pH of the solution is 9-13 and a precipitate is formed. After the precipitate is filtered out, rinse it repeatedly with deionized water, and use a vacuum pump at -0.1MPa negative pressure at the same time Suction filtration was carried out until the supernatant liquid obtained after suction filtration was mixed with Ba(NO 3 ) 2 Detect that there is no residual SO4 in the washing liquid 2- Until the filter cake D is obtained, the filter cake D is placed in a drying oven and dried at 110°C for 24 hours;

[0048] Step 3: Take by weighing 45.40g of Ce(NO 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com