Ternary NiO nanosheet@bimetallic CeCuOx microchip core-shell structure composite material as well as preparation and application of ternary NiO nanosheet@bimetallic CeCuOx microchip core-shell structure composite material

A technology of core-shell structure and composite materials, applied in metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, heterogeneous catalyst chemical elements, etc., can solve poor thermal stability, high cost, high surface area Easy to agglomerate and other problems, to achieve the effect of increasing oxygen vacancies and contact area, uniform pore size, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 CeCuO x The preparation of microchips, the specific steps are as follows:

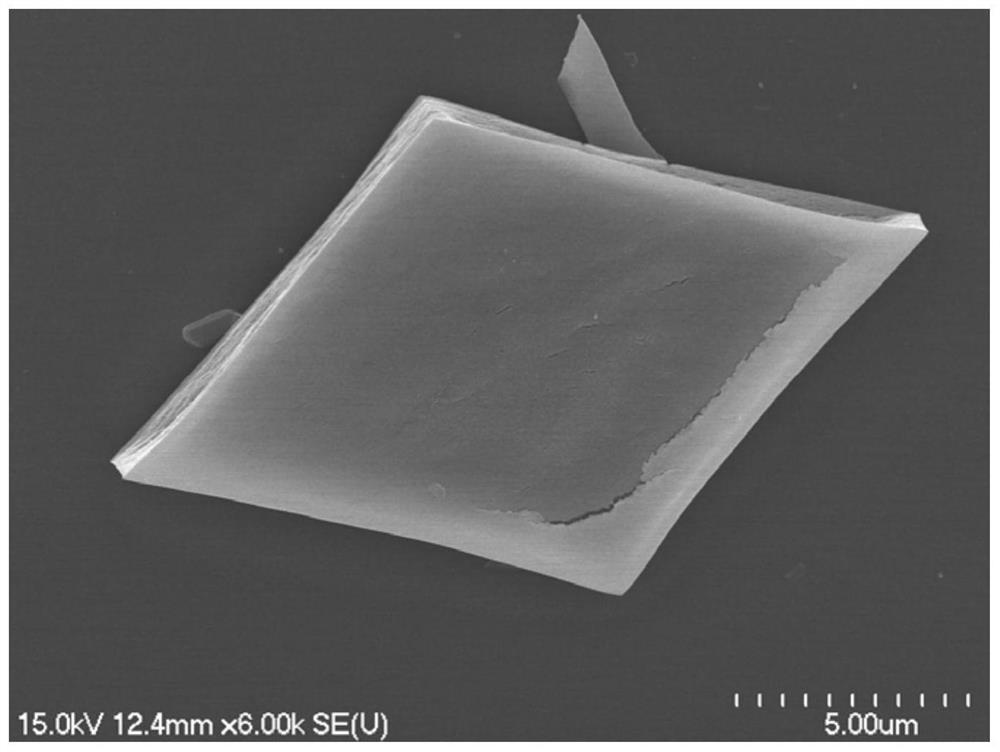

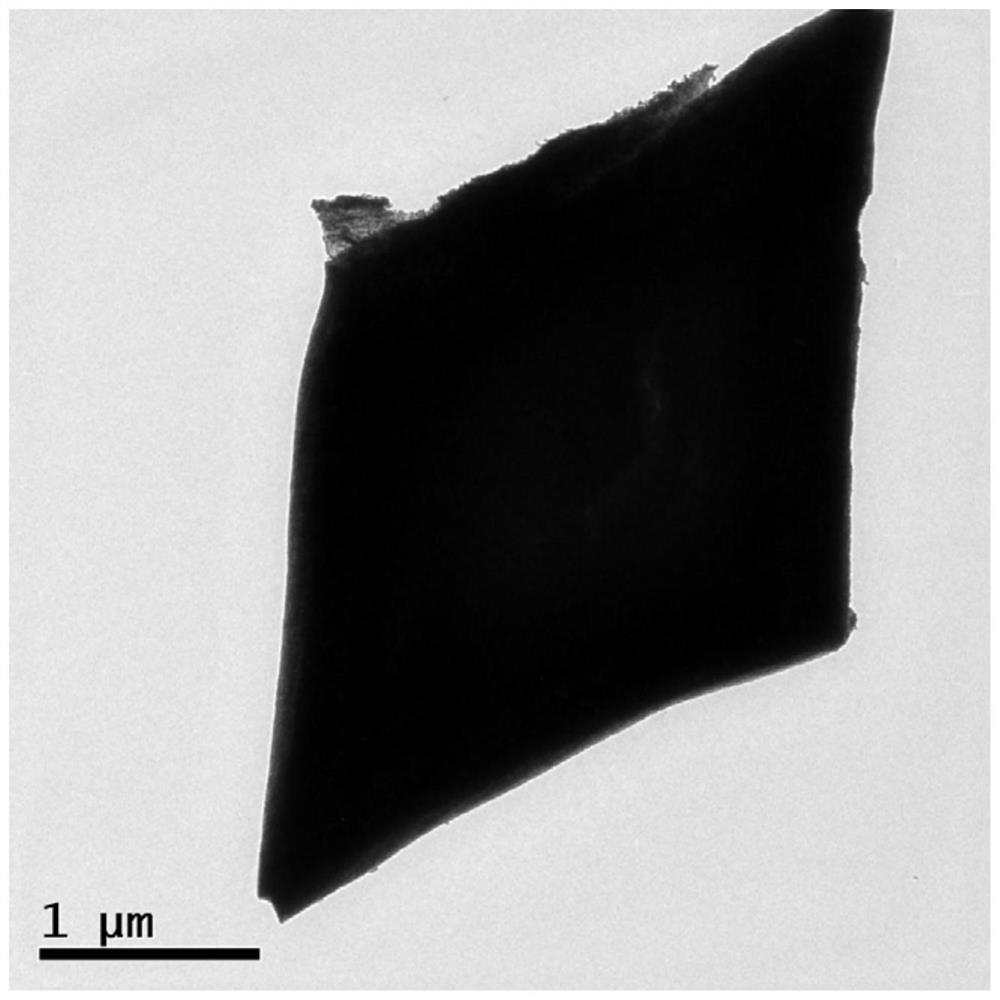

[0035] At room temperature, the Ce(NO 3 ) 3 ·6H 2 O (0.868 g, 2 mmol) and Cu (NO 3 ) 2 ·3H 2 O (0.242 g, 1 mmol) was dissolved in DMF (40 ml) and stirred at 1000 rpm for 2 h; H2 BDC (0.664 g, 4 mmol) was dissolved in DMF (40 ml) and stirred at 1000 rpm for 2 h. The two solutions were then mixed with ultrapure water (20 ml) in a stainless steel autoclave, subjected to solvothermal synthesis at 80 °C for 24 h, and the obtained blue precipitate CeCuBDC was washed several times with DMF and ethanol, and then heated at 65 °C C under vacuum for 6 h, then calcined CeCuBDC in air at 350 °C for 4 h at a rate of 3 °C / min from room temperature to 350 °C to obtain CeCuO x microchip. attached figure 1 for CeCuO x SEM image of the microchip, attached figure 2 for CeCuO x The TEM image of the microchip; it can be seen from the figure that the microchip has a two-dimensional layered struc...

Embodiment 2

[0036] Example 2 Ternary NiO nanosheets@bimetallic CeCuO x The preparation of the microchip core-shell structure composite material, the specific steps are as follows:

[0037] Nickel oxide is 3 times that of CeCuO x Mass calculation feed ratio, the molar ratio of 1:5 Ni (NO 3 ) 2 and urea were dissolved in 100mL solution with a water / alcohol volume ratio of 1 / 1, then, 100mg of prepared CeCuO was added x Microchip powder (Example 1), and the resulting solution was placed at 80°C for 2 hours under normal stirring. The product powder was filtered and washed, then dried at 90 °C, followed by calcination at 350 °C in an air atmosphere for 4 h at a heating rate of 3 °C / min to obtain ternary NiO nanosheets@bimetallic CeCuO x Microplate core-shell composite material, named 3Ni / CeCuO x (Indicates that NiO nanosheets, bimetallic CeCuO x The weight ratio of microchips is 3:1), and then perform performance and characterization tests.

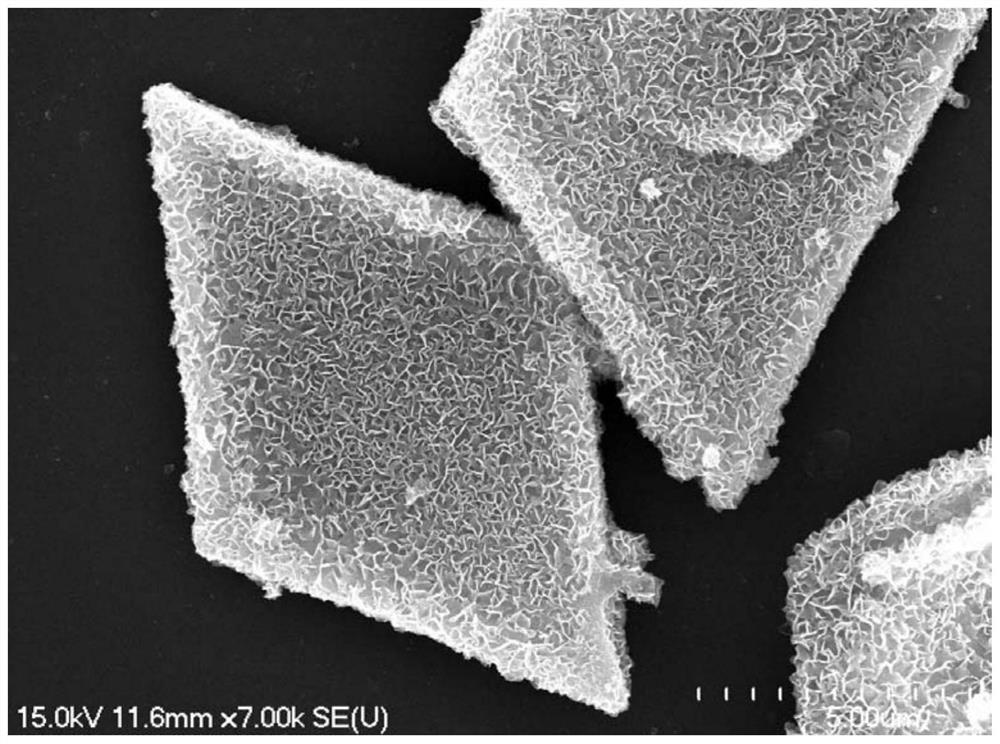

[0038] attached Figure 4 3Ni / CeCuO x SEM i...

Embodiment 3

[0041] Ternary NiO nanosheets@bimetallic CeCuO x The thermal catalysis conditions of the microchip core-shell structure composite material to toluene gas are: toluene concentration is 50 ppm (air is used as filling gas, purchased from Messer Air Liquide Co., Ltd.), and the amount of catalyst is 50 mg. According to the conventional method, the The catalyst was fixed on a fixed-bed reactor through a U-shaped tube, and the catalytic effect of the composite material on toluene gas under heating conditions was analyzed by gas chromatography, and the test condition was 36000 ml / (h∙g).

[0042] attached Figure 5 For ternary NiO nanosheets@bimetallic CeCuO x The thermocatalytic effect curve of microchip core-shell structure composites on toluene gas. attached by Figure 5 It can be seen that the present invention can be applied to the conversion of toluene at lower temperatures. Toluene pollution in the air mainly comes from building materials, interior decoration materials, livi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com