A kind of technique of cyclohexene oxidation

A cyclohexene and process technology, applied in the field of adipaldehyde preparation process, can solve the problems of high price, excessive oxidation, hindering industrial application, etc., and achieve the effect of improving product selectivity, high product selectivity, and strengthening material transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

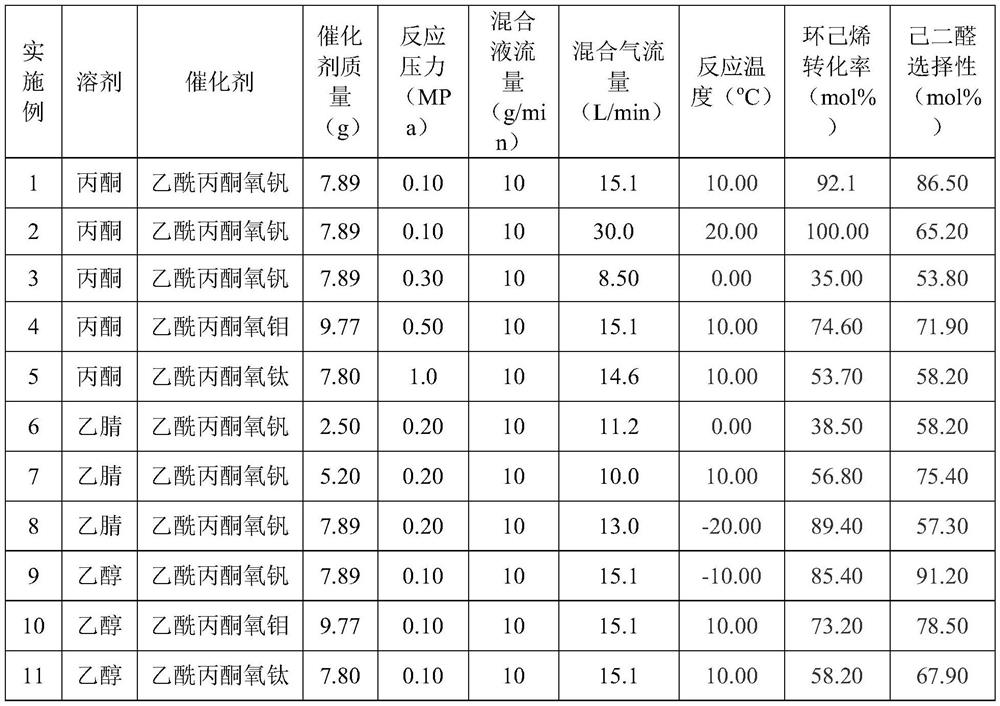

Examples

Embodiment 1

[0046] Cyclohexene is oxidized to adipaldehyde in the microchannel reactor of embodiment 1

[0047] 50 g of cyclohexene and 116 g of acetone were mixed to prepare a cyclohexene solution with a mass concentration of 30%, and 7.89 g of vanadyl acetylacetonate was added to the cyclohexene solution, and the mixed solution was obtained after ultrasonic vibration and uniform mixing;

[0048]A pump is used to inject the mixed solution into the microchannel reactor, and the flow rate of the mixed solution is 10g / min. At the same time, the mixed gas is injected into the microchannel reactor through a mass flow meter, and the flow rate of the mixed gas is controlled to be 15.1L / min. Composed of ozone, the ozone concentration is 100mg / L;

[0049] The reaction temperature in the microchannel reactor was 10° C., the reaction pressure was 0.10 MPa, and the materials were collected after 10 minutes of reaction, and analyzed by gas chromatography.

[0050] Cyclohexene is oxidized to adipalde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com