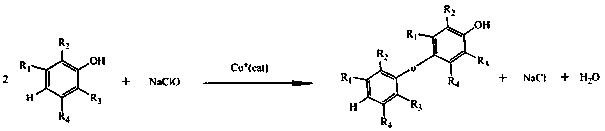

Preparation method for constructing compound with diphenyl ether structure

A technology of compound and diphenyl ether, which is applied in the field of preparation of diphenyl ether structure compounds, can solve the problems of difficult recycling of reaction solvents and catalysts, poisonous and harmful operators, long reaction time, etc., and achieves low cost of synthesis and preparation. The effect of good environment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of compound 1

[0025] In the embodiment of the present invention, phenol is heated, a catalyst is added, and sodium hypochlorite solution is added dropwise. After the reaction is completed, the temperature is lowered, the reaction solution is acidified, ether is added for extraction, part of the ether is evaporated under reduced pressure, the temperature is lowered to crystallize, and the product is obtained after suction filtration and water washing. , specifically: use water as the reaction medium, adopt a one-pot method to synthesize diphenyl ether compounds, mix phenol and metal cuprous ion catalyst cuprous chloride into the reaction kettle by one-pot method, and add sodium hypochlorite aqueous solution dropwise at the same time to directly prepare diphenyl ether compounds. Phenyl ether structure compound, at first, sodium hypochlorite is uniformly dissolved in water, makes sodium hypochlorite aqueous solution, by weight, sodium hypochlorite: water=1: 10...

Embodiment 2

[0027] Preparation of compound 2

[0028] In the embodiment of the present invention, heat 2,6-dimethylphenol, add catalyst, dropwise add sodium hypochlorite solution, after the reaction, cool down, acidify the reaction solution, add solvent for extraction, separate layers, evaporate part of the solvent from the organic phase under reduced pressure , cooling and crystallization, and suction filtration to obtain the product after washing with water. Specifically, using water as the reaction medium, a diphenyl ether compound is synthesized by a one-pot method, and 2,6-dimethylphenol and the catalyst cuprous iodide are synthesized by a one-pot method Mix, add dropwise sodium hypochlorite aqueous solution, directly prepare diphenyl ether structure compound, at first, sodium hypochlorite is uniformly dissolved in water, obtain sodium hypochlorite aqueous solution, wherein by weight, sodium hypochlorite: water=1: 10; 2,6-dimethylphenol : catalyst cuprous iodide=10:1, in molar ratio,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com