Preparation and application of a kind of reactive fatliquoring agent containing polyoxyalkylene epoxy group acrylate polymer

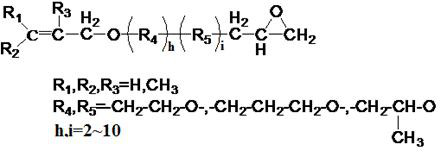

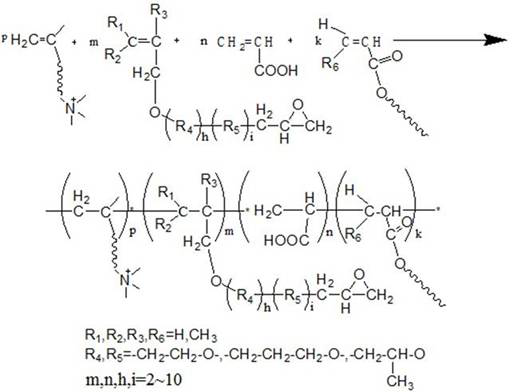

A technology of polyoxyalkylene epoxy acrylic acid and polyoxyalkylene epoxy ethylene is applied in the field of leather chemical synthesis and can solve the problems of easy oxidation, yellowing and migration resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

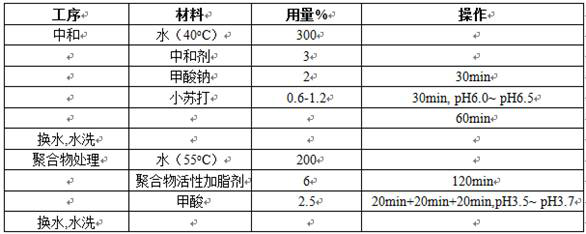

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 1.51g of emulsifier sodium lauryl sulfate in 55g of distilled water to form an aqueous emulsifier solution; add the aqueous solution of sodium lauryl sulfate into a 250mL four-necked flask, then heat it in a water bath to 80°C, turn on the stirrer to stir, and turn on Condensed water, while stirring, dropwise added 3.6g of acrylic acid, 12.88g of isooctyl acrylate and 27g of polyoxyalkylene epoxy vinyl monomer (relative molecular mass about 270), 4.67g of methacryloxy The aqueous solution prepared by ethyltrimethylammonium chloride and 20g distilled water and the aqueous potassium persulfate solution prepared by 2.02g potassium persulfate and 40g distilled water, the dropping time is controlled at 2.5 hours, and the constant temperature is reacted at 80°C for 2 hours, and finally cooled to room temperature, using a 30% aqueous sodium hydroxide solution to adjust the pH of the resulting reaction system to 6.5 to obtain a reactive fatliquoring agent containing a p...

Embodiment 2

[0032] Dissolve 2.10g of the emulsifier sodium dodecylbenzenesulfonate in 65g of distilled water to form an emulsifier aqueous solution; add the aqueous solution of sodium dodecylbenzenesulfonate into a 250mL four-necked flask, then heat it in a water bath to 80°C, and start stirring Stir with the mixer, turn on the condensed water, and add 2.5g of acrylic acid, 17.02g of 2-propylheptyl acrylate and 29.75g of polyoxyalkylene epoxy vinyl monomer (relative molecular mass about 350) dropwise to it while stirring. , the aqueous solution prepared by 2.91g dimethyl diallyl ammonium chloride and 20g distilled water and the aqueous solution of potassium persulfate prepared by 2.16g potassium persulfate and 54g distilled water, the dropping time is controlled at 3 hours, and the constant temperature reaction is carried out at 80°C After 2 hours, it was finally cooled to room temperature, and the pH of the obtained reaction system was adjusted to 6.5 with a 30% aqueous sodium hydroxide s...

Embodiment 3

[0034] Dissolve 1.2g of emulsifier sodium dodecylbenzenesulfonate in 40g of distilled water to form an emulsifier aqueous solution; add the aqueous solution of sodium dodecylbenzenesulfonate into a 250ml four-necked flask, then heat it in a water bath to 80°C, and start stirring Stir with the mixer, turn on the condensed water, and dropwise add 3.6g of acrylic acid, 21.3g of lauryl acrylate and 25.8g of polyoxyalkylene epoxy vinyl monomer (relative molecular mass about 430) to it while stirring, 3.73g The aqueous solution prepared by acryloyloxyethyltrimethylammonium chloride and 20g of distilled water and the aqueous solution of potassium persulfate prepared by 2.45g of potassium persulfate and 65g of distilled water, the dropping time is controlled at 2.5 hours, and the constant temperature reaction is carried out at 80°C for 2 hours , and finally cooled to room temperature, and using 30% aqueous sodium hydroxide solution to adjust the pH of the reaction system to 6.5 to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com