Method for preparing cobalt blue hybrid pigment by using quartz removed in natural mineral purification process

A technology of natural minerals and quartz, which is applied in the field of preparation of cobalt blue hybrid pigments, can solve problems such as easy generation of waste water, achieve the effects of improving reactivity, low temperature, and improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

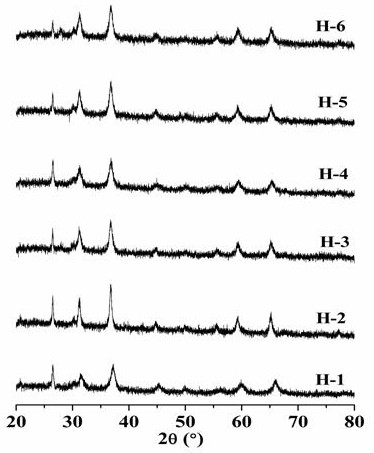

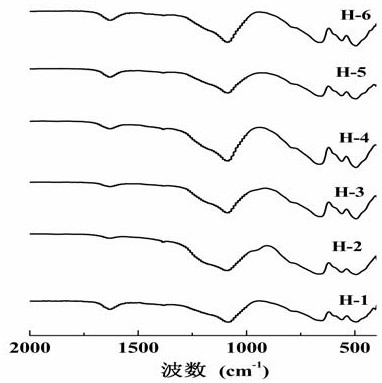

[0025] Mix 0.582 g of cobalt nitrate, 1.500 g of aluminum nitrate, 0.212 g of quartz and 0.750 g of heavy calcium carbonate, put them into a 50 mL zirconia grinding jar, add 30 g of zirconia balls with a diameter of 2 mm, and the ball-to-material ratio is 10; put it in a mill and grind it at 400rpm for 180 min to obtain a precursor; then calcinate the precursor at 1000ºC for 60 min to obtain a cobalt blue / quartz hybrid pigment, marked as H-1, which L * , a * , b * See Table 1 for color parameters.

Embodiment 2

[0027] 0.482 g Co 3 o 4 , 1.500 g of aluminum nitrate, 0.283 g of quartz and 0.700 g of calcite are mixed, put into a 50 mL zirconia grinding jar, add 60 g of zirconia balls with a diameter of 2 mm, and the ball-to-material ratio is 20; The precursor was prepared by grinding at 500 rpm for 120 min; then the precursor was calcined at 900ºC for 120 min to obtain a cobalt blue / quartz hybrid pigment, labeled as H-2, which L * , a * , b * See Table 1 for color parameters.

Embodiment 3

[0029] 0.315 g Co 2 o 3 , 0.408 g of aluminum nitrate, 0.141 g of quartz and 0.445 g of calcium hydroxide are mixed, put into a 50 mL zirconia grinding tank, add 50 g of zirconia balls with a diameter of 2 mm, and the ball-to-material ratio is 40; The precursor was prepared by grinding at 500 rpm for 240 min; then the precursor was calcined at 1000ºC for 120 min to obtain a cobalt blue / quartz hybrid pigment, labeled as H-3, which L * , a * , b * See Table 1 for color parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com