Self-repairing hydrogel microcapsule composite material and preparation method thereof, self-repairing lithium-sulfur battery cathode and battery

A composite material and lithium-sulfur battery technology, which is applied in non-aqueous electrolyte battery electrodes, battery electrodes, lithium batteries, etc., can solve problems affecting battery performance, low sulfur utilization rate, and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

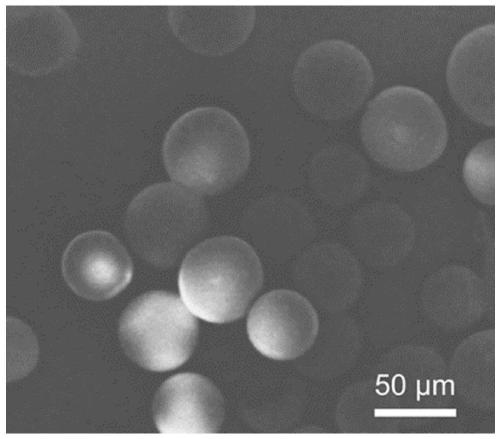

[0036] A preparation method of self-repairing hydrogel microcapsule composite material, comprising the following steps:

[0037] 1) Disperse 184 μL of phytic acid and 84 μL of pyrrole in 1 mL of isopropanol, and obtain mixed solution A after ultrasonication; take another beaker and dissolve 0.184 g of ammonium sulfate in 2 mL of deionized water to obtain an aqueous solution of ammonium sulfate; A. Ammonium sulfate aqueous solution and deionized water are mixed according to the volume ratio of (1~1.2):(0.8~1):(1~2) to obtain a viscous colorless precursor solution B;

[0038] 2) Disperse 0.2mL of 2-hydroxy-2-methylpropiophenone and 20mL of trimethylol propane ethoxylate triacrylate in 20mL of absolute ethanol, after mixing evenly, place the resulting solution in an oven at 60-80°C for 12h Evaporate absolute ethanol completely to obtain mixed solution C;

[0039] 3) Disperse 20 g of polyvinyl alcohol in 1000 mL of deionized water, place in a water bath and stir at a constant tem...

Embodiment 2

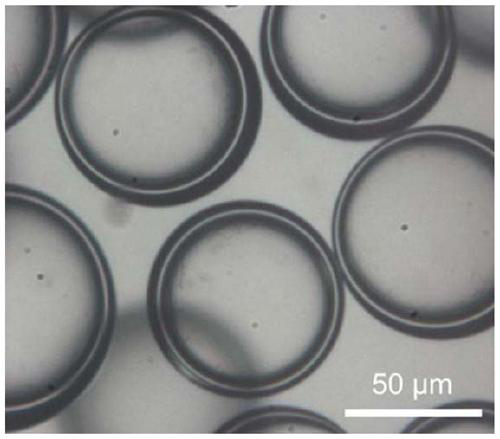

[0042] A preparation method of self-repairing hydrogel microcapsule composite material, comprising the following steps:

[0043] 1) Disperse 184 μL of phytic acid and 84 μL of pyrrole in 1 mL of isopropanol, and obtain mixed solution A after ultrasonication; take another beaker and dissolve 0.184 g of ammonium sulfate in 2 mL of deionized water to obtain an aqueous solution of ammonium sulfate; A. Ammonium sulfate aqueous solution and deionized water are mixed according to the volume ratio of (1~1.2):(0.8~1):(1~2) to obtain a viscous colorless precursor solution B;

[0044] 2) Disperse 0.2mL of 2-hydroxy-2-methylpropiophenone and 20mL of trimethylol propane ethoxylate triacrylate in 20mL of absolute ethanol, after mixing evenly, place the resulting solution in an oven at 60-80°C for 12h , to completely evaporate the absolute ethanol to obtain a mixed solution C;

[0045] 3) Disperse 20 g of polyvinyl alcohol in 1000 mL of deionized water, place in a water bath and stir at a c...

Embodiment 3

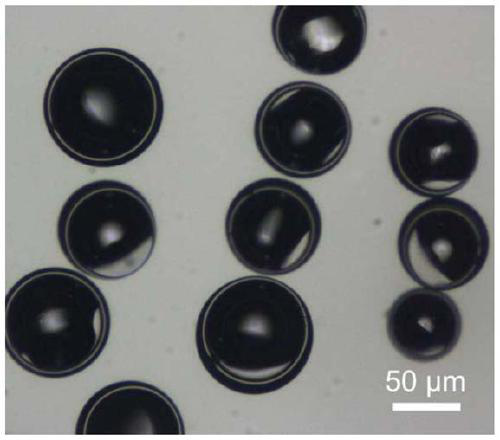

[0048] A preparation method of self-repairing hydrogel microcapsule composite material, comprising the following steps:

[0049] 1) Disperse 184 μL of phytic acid and 84 μL of pyrrole in 1 mL of isopropanol, and obtain mixed solution A after ultrasonication; take another beaker and dissolve 0.184 g of ammonium sulfate in 2 mL of deionized water to obtain an aqueous solution of ammonium sulfate; A. Ammonium sulfate aqueous solution and deionized water are mixed according to the volume ratio of (1~1.2):(0.8~1):(1~2) to obtain a viscous colorless precursor solution B;

[0050] 2) Disperse 0.4mL of 2-hydroxy-2-methylpropiophenone and 20mL of trimethylol propane ethoxylate triacrylate in 20mL of absolute ethanol, after mixing evenly, place the resulting solution in an oven at 60-80°C for 12h , baked until the complete evaporation of absolute ethanol to obtain a mixed solution C;

[0051] 3) Disperse 20 g of polyvinyl alcohol in 1000 mL of deionized water, place in a water bath and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com