Preparation and application of modified ammonium oxytrifluorotitanate for lithium ion battery

An ammonium oxytitanate, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electronic conductivity of base materials, small ion diffusion coefficient, and limited application of base materials, etc. The effect of simple preparation method, accelerated migration rate, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of the modified ammonium trifluorooxytitanate that is used for lithium ion battery, concrete implementation steps are as follows:

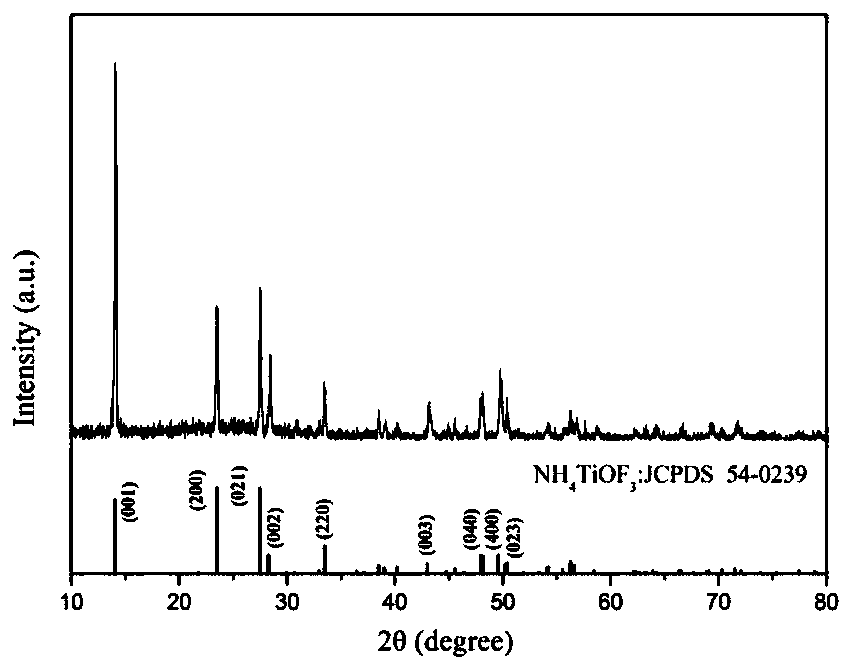

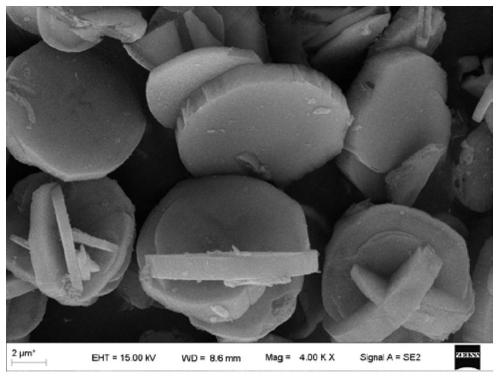

[0038] Step 1, NH 4 TiOF 3 Preparation of:

[0039](1) Add 1.3g of ammonium fluoride to 10mL of deionized water, after the ammonium fluoride is completely dissolved, add 100mL of ethylene glycol and 3.25g of titanyl sulfate-sulfuric acid hydrate, and stir the mixture evenly to form a uniform solution;

[0040] (2) Transfer the uniformly stirred solution to a 200mL stainless steel autoclave, and react at 200°C for 70min;

[0041] (3) After cooling to room temperature, wash the product three times with deionized water, then dry the product in an oven at 60°C for 12 hours, and pass through a 300-mesh sieve to obtain NH 4 TiOF 3 (referred to as NTF-AP);

[0042] Step 2. Modified NH 4 TiOF 3 Preparation of:

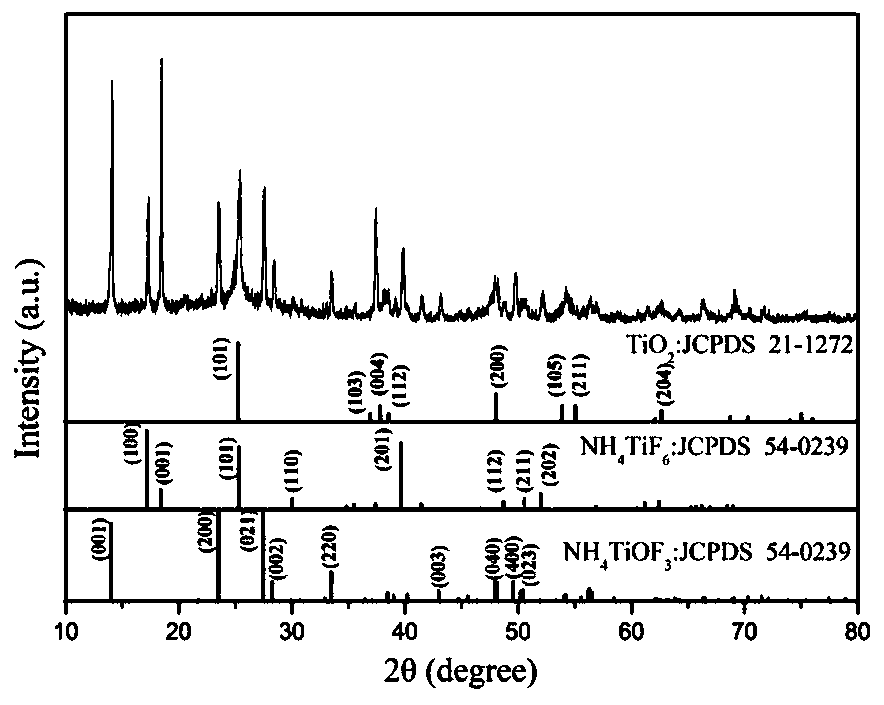

[0043] The obtained NTF-AP was annealed with argon for 2 hours at 150° C. in a tube furnace, and take...

Embodiment 2

[0046] A kind of modified ammonium trifluorooxytitanate for lithium ion battery, concrete implementation steps are as follows:

[0047] Step 1, NH 4 TiOF 3 Preparation of:

[0048] (1) Add 1.3g of ammonium fluoride to 10mL of deionized water, after the ammonium fluoride is completely dissolved, add 100mL of ethylene glycol and 3.25g of titanyl sulfate-sulfuric acid hydrate, and stir the mixture evenly to form a uniform solution;

[0049] (2) Transfer the uniformly stirred solution to a 200mL stainless steel autoclave, and react at 200°C for 70min;

[0050] (3) After cooling to room temperature, wash the product three times with deionized water, then dry the product in an oven at 60°C for 12 hours, and pass through a 300-mesh sieve to obtain NH 4 TiOF 3 (referred to as NTF-AP);

[0051] Step 2. Modified NH 4 TiOF 3 Preparation of:

[0052] The obtained NTF-AP was annealed with argon for 2 hours at 250° C. in a tube furnace, and taken out after the furnace temperature wa...

Embodiment 3

[0055] A kind of modified ammonium trifluorooxytitanate for lithium ion battery, concrete implementation steps are as follows:

[0056] Step 1, NH 4 TiOF 3 Preparation of:

[0057] (1) Add 1.3g of ammonium fluoride to 10mL of deionized water, after the ammonium fluoride is completely dissolved, add 100mL of ethylene glycol and 3.25g of titanyl sulfate-sulfuric acid hydrate, and stir the mixture evenly to form a uniform solution;

[0058] (2) Transfer the uniformly stirred solution to a 200mL stainless steel autoclave, and react at 200°C for 70min;

[0059] (3) After cooling to room temperature, wash the product three times with deionized water, then dry the product in an oven at 60°C for 12 hours, and pass through a 300-mesh sieve to obtain NH 4 TiOF 3 (referred to as NTF-AP);

[0060] Step 2. Modified NH 4 TiOF 3 Preparation of:

[0061] The obtained NTF-AP was annealed with argon for 2 hours at 350° C. in a tube furnace, and taken out after the furnace temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com