Metal nickel/nitrogen-doped carbon nanotube and lithium-sulfur battery composite positive electrode material thereof

A composite cathode material and nitrogen-doped carbon technology, which is applied in carbon nanotubes, battery electrodes, lithium batteries, etc., can solve the problems of poor conductivity and low utilization rate of sulfur cathode active materials, and achieve high sulfur content, low cost, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

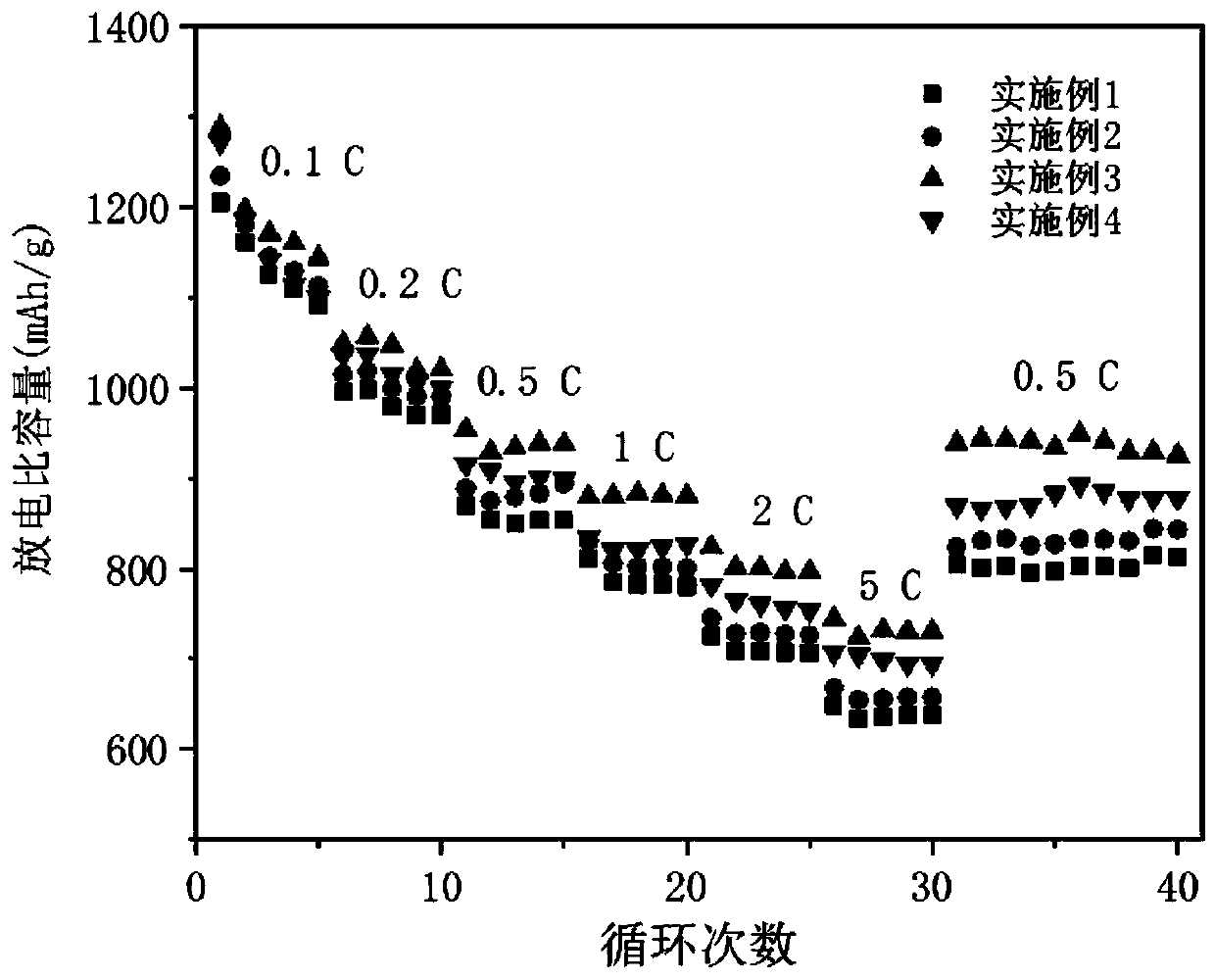

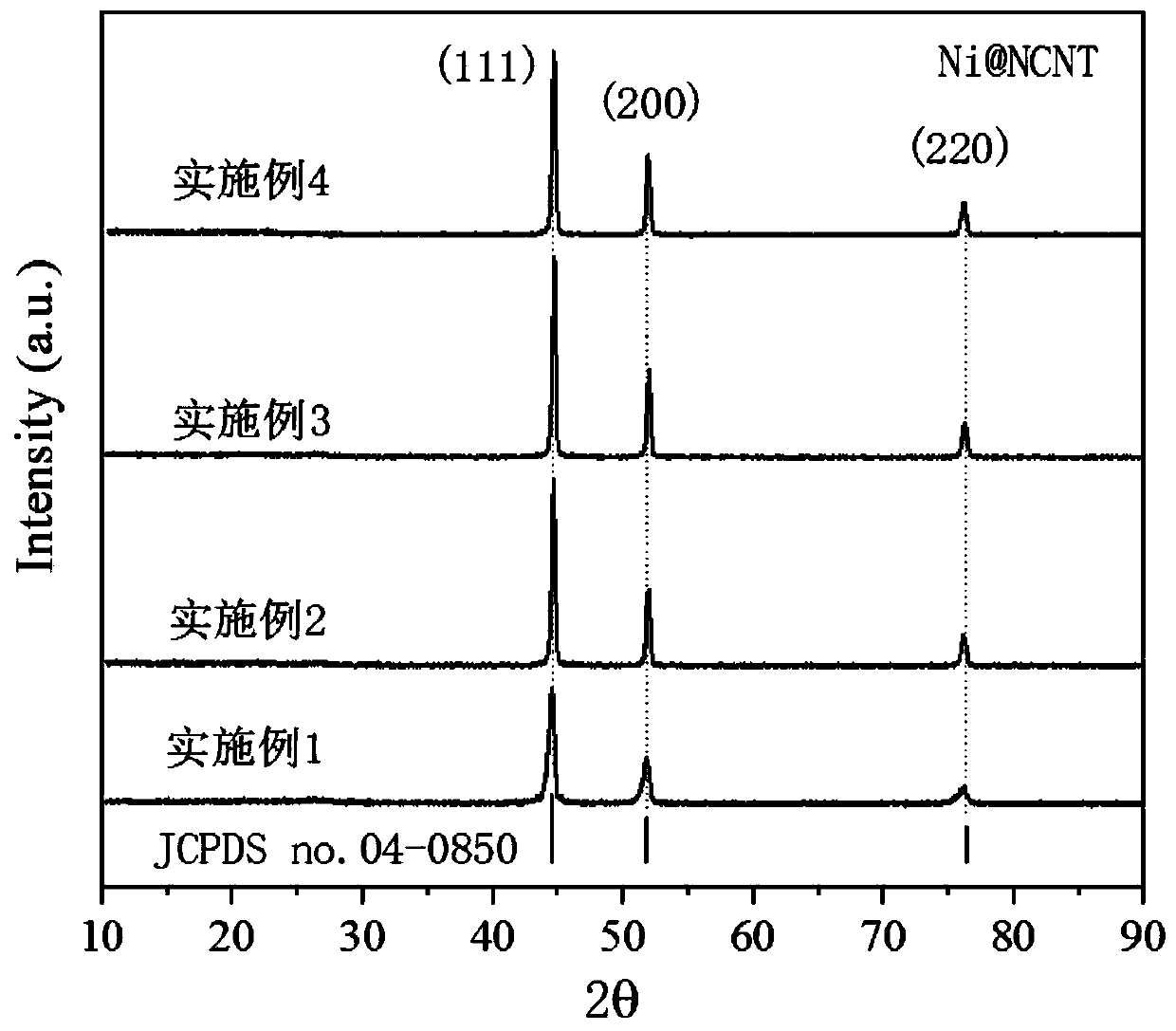

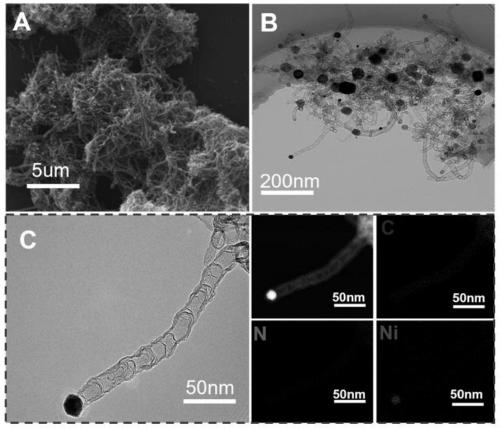

[0037] A metal nickel / nitrogen-doped carbon nanotube and its lithium-sulfur battery composite cathode material, specifically prepared according to the following steps:

[0038] Step 1. Weigh 0.05g of nickel nitrate and 5g of urea and dissolve them in 50mL of deionized water. After evaporating the solvent to dryness, grind them evenly to obtain a powder substance. The temperature was raised to 800°C at a certain rate, carbonized for 4 hours, and cooled to room temperature to obtain metal nickel / nitrogen-doped carbon nanotubes (referred to as Ni@NCNT-1).

[0039] Step 2: Mix the Ni@NCNT-1 and sulfur element at a mass ratio of 1:4, grind evenly to obtain a mixture of Ni@NCNT-1 and sulfur element, transfer it to a reaction kettle, and seal it under an argon atmosphere. The reaction kettle was placed in a muffle furnace and kept at 155°C for 12 hours; then cooled to room temperature to obtain a lithium-sulfur battery composite cathode material (denoted as S / Ni@NCNT-1).

Embodiment 2

[0041] A metal nickel / nitrogen-doped carbon nanotube and its lithium-sulfur battery composite cathode material, specifically prepared according to the following steps:

[0042]Step 1, weigh 0.05g of nickel nitrate and 5g of cyanamide and dissolve them in 50mL of deionized water. After evaporating the solvent to dryness, grind them evenly to obtain a powder substance. Put the obtained powder precursor into a tube furnace. Raise the temperature to 800°C at a rate of 1 / min, carbonize for 4 hours, and cool to room temperature to obtain metal nickel / nitrogen-doped carbon nanotubes (referred to as Ni@NCNT-2).

[0043] Step 2: Mix the Ni@NCNT-2 and sulfur element at a mass ratio of 1:4, grind evenly to obtain a mixture of Ni@NCNT-2 and sulfur element, transfer it to a reaction kettle, and seal it under an argon atmosphere. The reaction kettle was placed in a muffle furnace and kept at 155°C for 12h; then cooled to room temperature to obtain a lithium-sulfur battery composite cathode ...

Embodiment 3

[0045] A metal nickel / nitrogen-doped carbon nanotube and its lithium-sulfur battery composite cathode material, specifically prepared according to the following steps:

[0046] Step 1. Weigh 0.05g of nickel nitrate and 5g of dicyandiamide and dissolve them in 50mL of deionized water. After evaporating the solvent to dryness, grind them evenly to obtain a powder substance. Put the obtained powder precursor into a tube furnace. The temperature was raised to 800°C at a rate of 1 / min, carbonized for 4 hours, and cooled to room temperature to obtain metal nickel / nitrogen doped carbon nanotubes (referred to as Ni@NCNT-3).

[0047] Step 2: Mix the Ni@NCNT-3 and sulfur element at a mass ratio of 1:4, grind evenly to obtain a mixture of Ni@NCNT-3 and sulfur element, transfer it to a reaction kettle, and seal it under an argon atmosphere. The reaction kettle was placed in a muffle furnace and kept at 155°C for 12h; then cooled to room temperature to obtain a lithium-sulfur battery compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com