Novel polymer water-based fire extinguishing agent and preparation method thereof

A technology of polymer and fire extinguishing agent, which is applied in fire protection equipment and other directions, can solve the problems of single fire extinguishing object, cannot be extinguished at the same time, and weak anti-re-ignition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

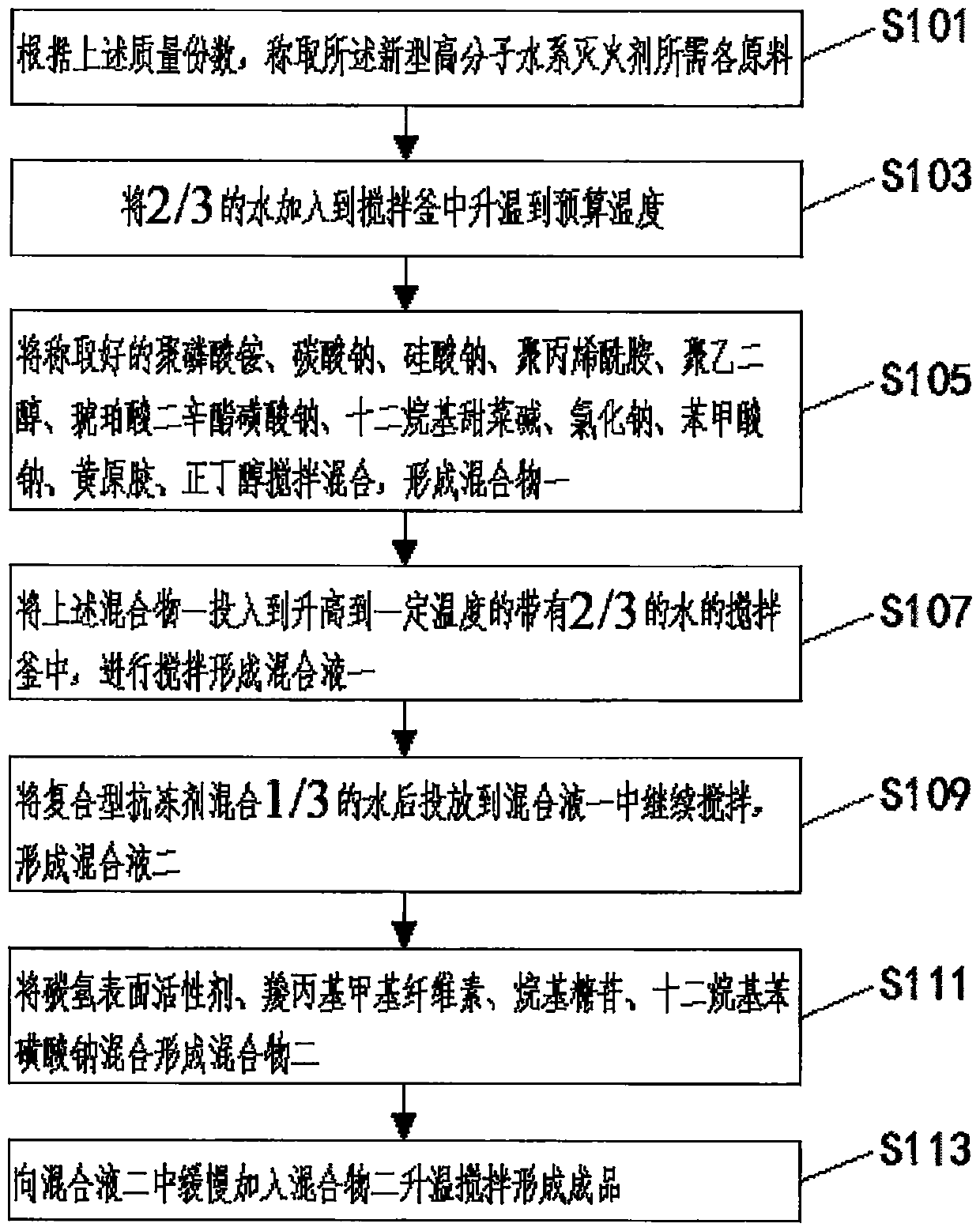

Method used

Image

Examples

Embodiment 1

[0061] A new polymer water system fire extinguishing agent is made of the following raw materials in parts by mass:

[0062] Ammonium polyphosphate 2g, sodium carbonate 6g, sodium silicate 6g, polyacrylamide 10g, polyethylene glycol 2g, dioctyl sulfosuccinate sodium 6g, lauryl betaine 12g, sodium chloride 6g, sodium benzoate 5g, xanthan gum 7g, n-butanol 15g, compound antifreeze agent 8g, foaming agent 8g, surfactant 6g, surfactant 8g and water 80g.

[0063] Wherein, the surfactant includes the following raw material components: hydrocarbon surfactant 2g, carboxypropyl methylcellulose 6g.

[0064] The foaming agent includes the following raw material components: 8 g of alkyl glycosides.

[0065] The surfactant includes the following raw material components: 6 g of sodium dodecylbenzenesulfonate.

[0066] The composite antifreeze agent includes the following raw material components: 2g of calcium chloride, 2g of ethanol and 4g of ethylene glycol.

[0067] The preparation of ...

Embodiment 2

[0076] A new polymer water system fire extinguishing agent is made of the following raw materials in parts by mass:

[0077] Ammonium polyphosphate 3g, sodium carbonate 7g, sodium silicate 7g, polyacrylamide 11g, polyethylene glycol 3g, dioctyl sulfosuccinate sodium 7g, lauryl betaine 14g, sodium chloride 7g, sodium benzoate 7g, xanthan gum 10g, n-butanol 20g, compound antifreeze agent 11g, foaming agent 9g, surfactant 8g, surfactant 11g and water 90g.

[0078] Wherein, the surfactant includes the following raw material components: 4g of hydrocarbon surfactant and 7g of carboxypropylmethylcellulose.

[0079] The foaming agent includes the following raw material components: 9 g of alkyl glycosides.

[0080] The surfactant includes the following raw material components: sodium dodecylbenzenesulfonate 8g.

[0081] The composite antifreeze agent includes the following raw material components: 3g of calcium chloride, 3g of ethanol and 5g of ethylene glycol.

[0082] The preparat...

Embodiment 3

[0091] A new polymer water system fire extinguishing agent is made of the following raw materials in parts by mass:

[0092] Ammonium polyphosphate 4g, sodium carbonate 8g, sodium silicate 8g, polyacrylamide 12g, polyethylene glycol 4g, dioctyl sulfosuccinate sodium 8g, lauryl betaine 16g, sodium chloride 8g, sodium benzoate 9g, xanthan gum 13g, n-butanol 25g, compound antifreeze agent 14g, foaming agent 10g, surfactant 10g, surfactant 14g and water 100g.

[0093] Wherein, the surfactant includes the following raw material components: hydrocarbon surfactant 6g, carboxypropyl methylcellulose 8g.

[0094] The foaming agent includes the following raw material components: 10 g of alkyl glycosides.

[0095] The surfactant comprises the following raw material components: 10 g of sodium dodecylbenzenesulfonate.

[0096] The composite antifreeze agent comprises the following raw material components: 4g of calcium chloride, 4g of ethanol and 6g of ethylene glycol.

[0097] The prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com