Water-based high-temperature-resistant coating for high-temperature coating, and preparation method thereof

A high-temperature-resistant coating and high-temperature-resistant technology, which is applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems that water-based coatings cannot be directly coated with high-temperature coatings, and achieve strong bonding, good thermal stability, and dielectric strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

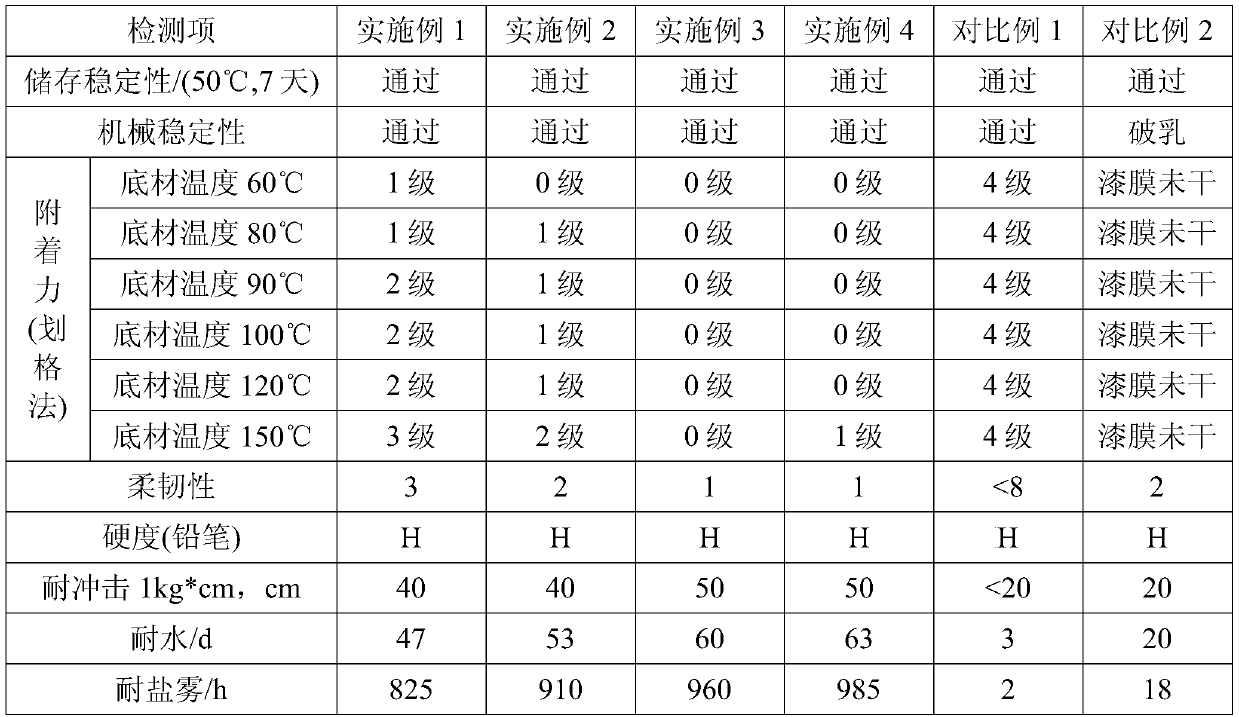

Examples

Embodiment 1

[0038] A water-based high-temperature resistant coating for high-temperature coating, including the following components in parts by weight: 30 parts of high-temperature resistant emulsion, 0.7 parts of silicone defoamer, 1.5 parts of amine neutralizer, 1.5 parts of silane coupling agent, phosphoric acid ester 1.5 parts of coupling agent, 0.3 parts of substrate wetting agent, 2 parts of film-forming aid (propylene glycol methyl ether), 4 parts of pigment (titanium dioxide), 26 parts of filler (3 parts of mica powder, 6 parts of iron-titanium powder, mica 4 parts of iron oxide, 13 parts of barium sulfate), 18 parts of distilled water I, 1.2 parts of thickener, and 1.2 parts of distilled water II.

[0039] The preparation method of the water-based high-temperature-resistant coating that is used for high-temperature coating, concrete steps are as follows:

[0040] (1) Add 30 parts of high-temperature-resistant emulsion into the reaction tank I, control the stirring speed to 300-6...

Embodiment 2

[0045] A water-based high-temperature-resistant coating for high-temperature coating, including the following components in parts by weight: 40 parts of high-temperature resistant emulsion, 0.7 parts of silicone defoamer, 1.6 parts of amine neutralizer, 1.5 parts of silane coupling agent, phosphate ester 1.5 parts of coupling agent, 0.3 parts of substrate wetting agent, 2.4 parts of film-forming aid (propylene glycol methyl ether), 4 parts of pigment (titanium dioxide), 26 parts of filler (3 parts of mica powder, 6 parts of iron-titanium powder, mica Iron oxide 4 parts, barium sulfate 13 parts), distilled water I 17 parts, thickener 1.2 parts, distilled water II 1.2 parts.

[0046] The preparation method of the water-based high-temperature-resistant coating that is used for high-temperature coating, concrete steps are as follows:

[0047] (1) Add 40 parts of high-temperature-resistant emulsion into the reaction tank I, control the stirring speed to 300-600rpm / min, control the ...

Embodiment 3

[0052] A water-based high-temperature-resistant coating for high-temperature coating, including the following components in parts by weight: 50 parts of high-temperature resistant emulsion, 0.7 parts of silicone defoamer, 1.8 parts of amine neutralizer, 1.5 parts of silane coupling agent, phosphoric acid ester 1.5 parts of coupling agent, 0.3 parts of substrate wetting agent, 3.0 parts of film-forming aid (propylene glycol methyl ether), 4 parts of pigment (titanium dioxide), 26 parts of filler (3 parts of mica powder, 6 parts of iron-titanium powder, mica 4 parts of iron oxide, 13 parts of barium sulfate), 16 parts of distilled water I, 1.2 parts of thickener, and 1.2 parts of distilled water II.

[0053] The preparation method of the water-based high-temperature-resistant coating that is used for high-temperature coating, concrete steps are as follows:

[0054] (1) Add 50 parts of high-temperature-resistant emulsion into the reaction tank I, control the stirring speed to 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com