Full-spectrum response bismuth oxide/silver phosphate/carbon nanotube sponge composite photocatalyst for drilling waste liquid treatment and preparation method and application thereof

A technology of carbon nanotube sponge and drilling waste fluid, which is applied in the direction of physical/chemical process catalysts, mining wastewater treatment, chemical instruments and methods, etc. It can solve the problem of weak adsorption capacity of non-polar organic matter, lack of adsorption and degradation, and restriction of photocatalysis Effectiveness and other issues, to achieve the effect of improving catalytic activity, improving separation rate, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

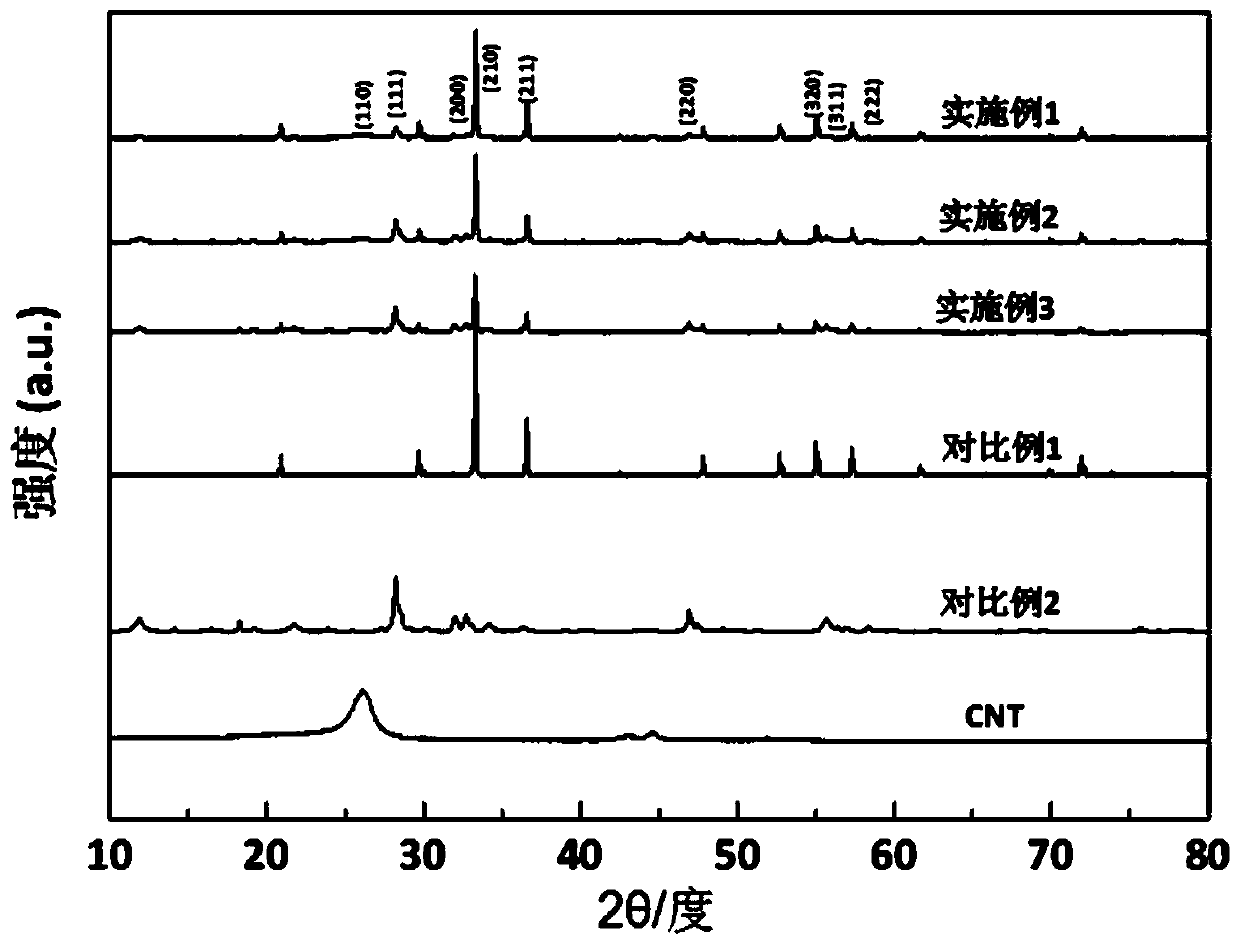

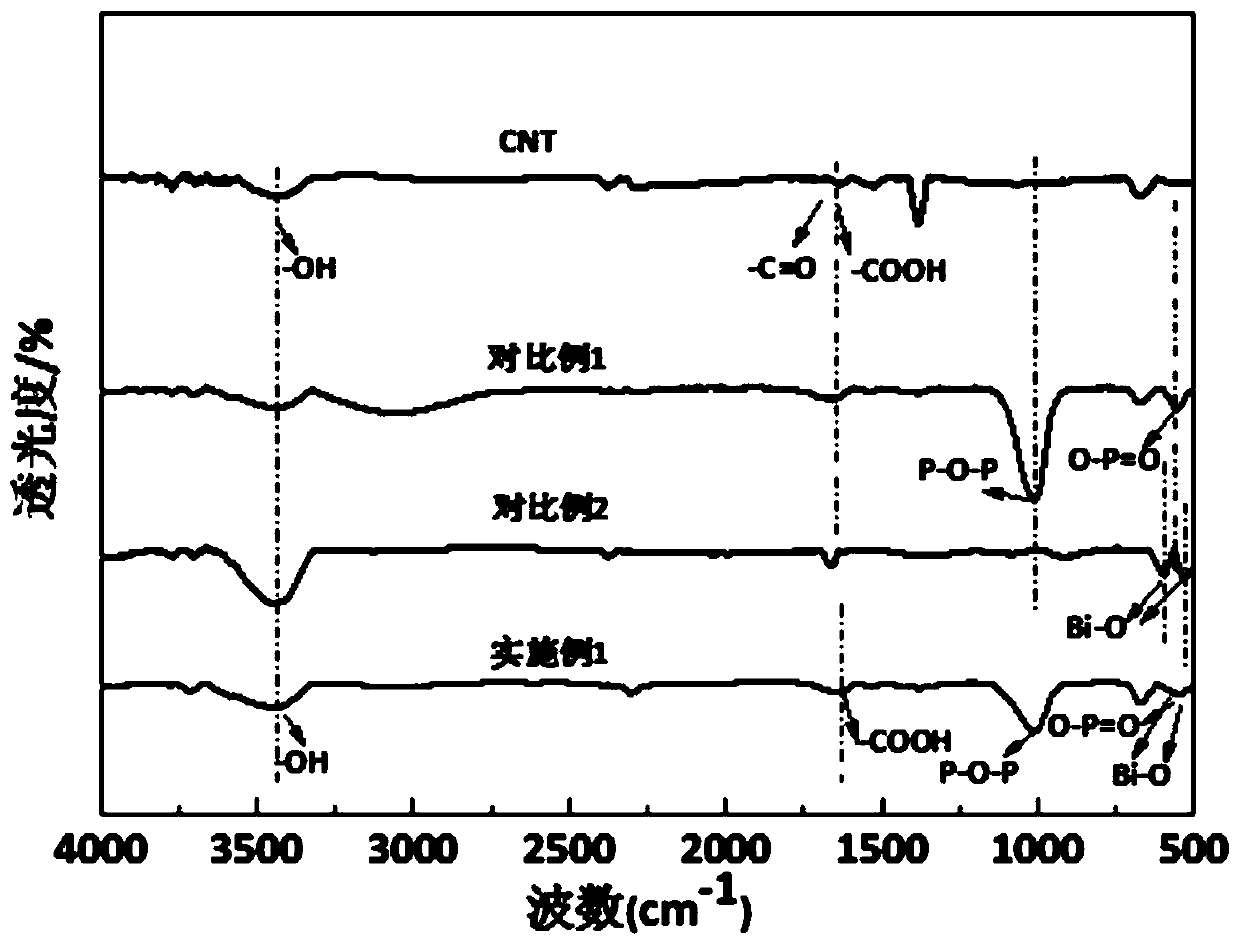

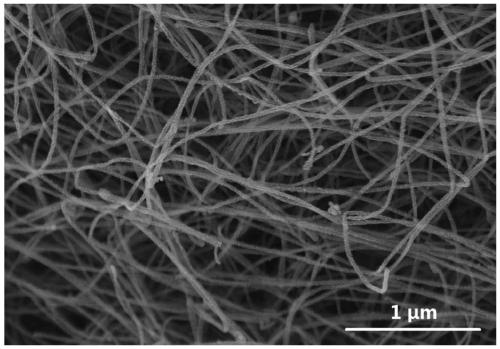

Embodiment 1

[0046] A method for preparing a full-spectrum response bismuth oxide / silver phosphate / carbon nanotube sponge composite photocatalyst for drilling waste fluid treatment, comprising the following steps:

[0047] (1) 1.5g silver nitrate is ultrasonically dispersed in the mixed solvent of 100mL ethanol, ethylene glycol and water, wherein, ethanol: ethylene glycol: the volume ratio of water is 1:1:9, obtains the organic alcohol aqueous solution of silver nitrate, Then put 0.3g carbon nanotube sponge into the organic alcohol aqueous solution of silver nitrate, under the condition of 25 ℃, stir for 1 hour with the stirring speed of 300r / min on the magnetic stirrer, make the porous structure of carbon nanotube sponge Uniformly adsorb silver nitrate in the medium to obtain a carbon nanotube sponge / silver nitrate mixture; uniformly disperse 0.5g disodium hydrogen phosphate in 100mL water to obtain a disodium hydrogen phosphate solution, which is added dropwise to carbon nanotube sponge / n...

Embodiment 2

[0054] A method for preparing a full-spectrum response bismuth oxide / silver phosphate / carbon nanotube sponge composite photocatalyst for drilling waste fluid treatment, comprising the following steps:

[0055] (1) 1.5g silver nitrate is ultrasonically dispersed in the mixed solvent of 100mL ethanol, ethylene glycol and water, wherein, ethanol: ethylene glycol: the volume ratio of water is 1:1:9, obtains the organic alcohol aqueous solution of silver nitrate, Then put 0.3g carbon nanotube sponge into the organic alcohol aqueous solution of silver nitrate, under the condition of 25 ℃, stir for 1 hour with the stirring speed of 300r / min on the magnetic stirrer, make the porous structure of carbon nanotube sponge Uniformly adsorb silver nitrate in the medium to obtain a carbon nanotube sponge / silver nitrate mixture; uniformly disperse 0.5g disodium hydrogen phosphate in 100mL water to obtain a disodium hydrogen phosphate solution, which is added dropwise to carbon nanotube sponge / n...

Embodiment 3

[0059] A method for preparing a full-spectrum response bismuth oxide / silver phosphate / carbon nanotube sponge composite photocatalyst for drilling waste fluid treatment, comprising the following steps:

[0060] (1) 1.5g silver nitrate is ultrasonically dispersed in the mixed solvent of 100mL ethanol, ethylene glycol and water, wherein, ethanol: ethylene glycol: the volume ratio of water is 1:1:9, obtains the organic alcohol aqueous solution of silver nitrate, Then put 0.3g carbon nanotube sponge into the organic alcohol aqueous solution of silver nitrate, under the condition of 25 ℃, stir for 1 hour with the stirring speed of 300r / min on the magnetic stirrer, make the porous structure of carbon nanotube sponge Uniformly adsorb silver nitrate in the medium to obtain a carbon nanotube sponge / silver nitrate mixture; uniformly disperse 0.5g disodium hydrogen phosphate in 100mL water to obtain a disodium hydrogen phosphate solution, which is added dropwise to carbon nanotube sponge / n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com