Preparation method and application of nitrogen-doped porous carbon fiber material

A nitrogen-doped porous carbon and fiber material technology, applied in the chemical characteristics of fibers, the manufacture of conductive/antistatic filaments, the manufacture of hybrid/electric double-layer capacitors, etc. Improved conductivity and surface hydrophilicity, good electrochemical performance, and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

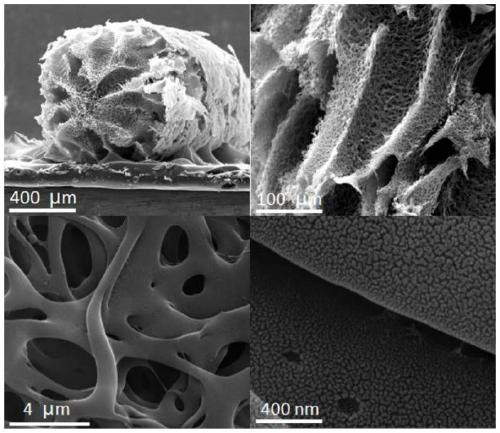

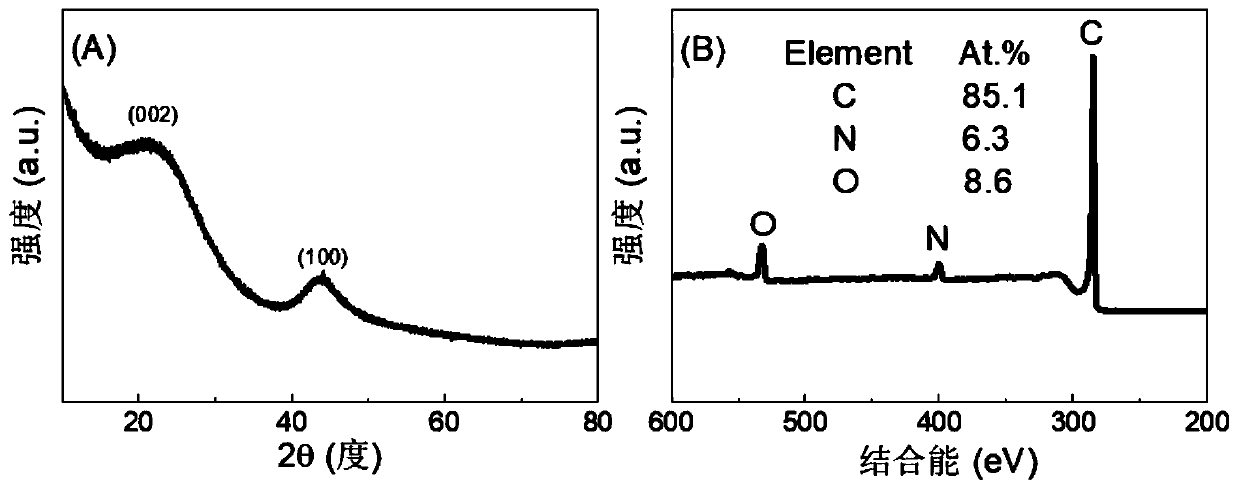

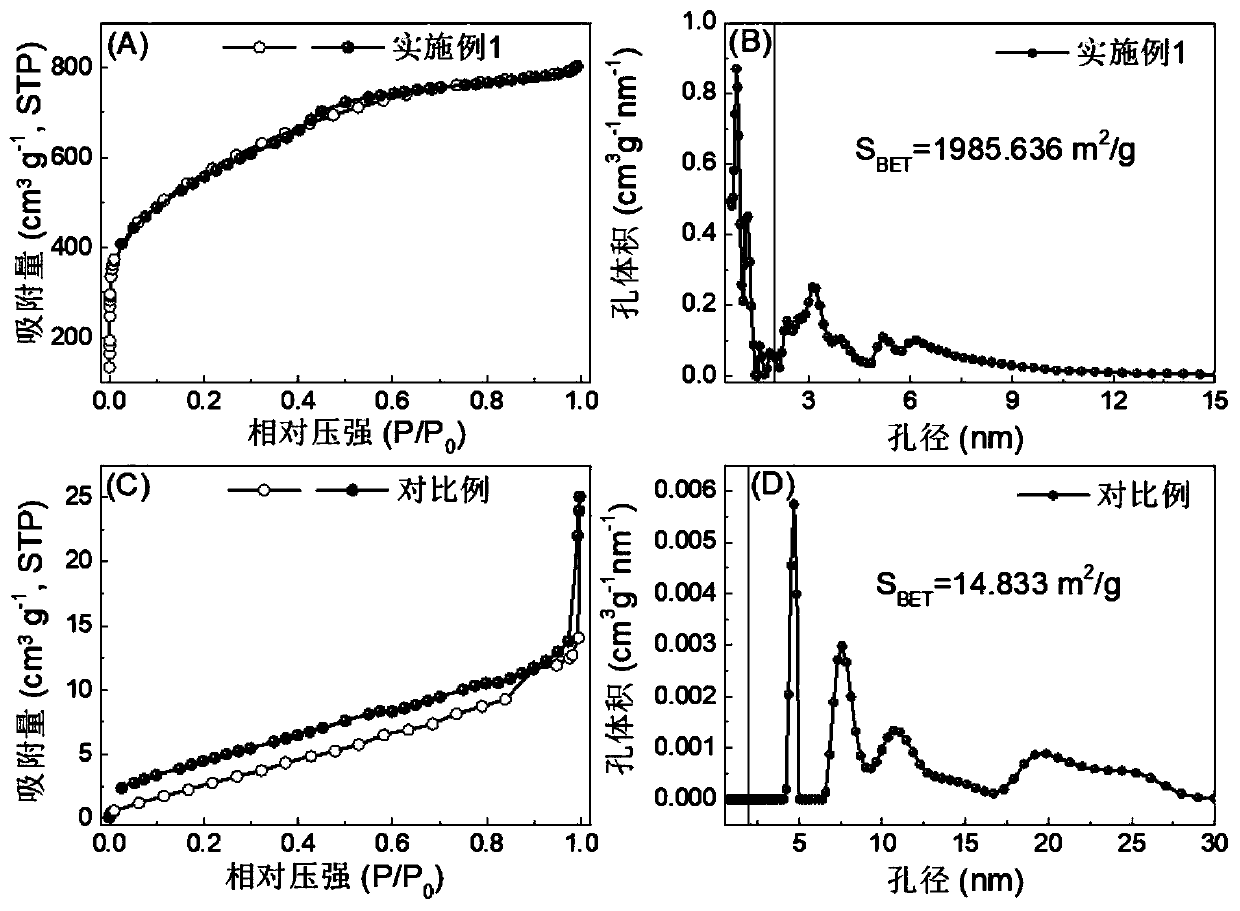

[0044] A preparation method of nitrogen-doped porous carbon fiber material, specifically comprising the steps of:

[0045] (1) Weigh 0.7g polyacrylonitrile and 0.7g polyvinylpyrrolidone according to the mass ratio of 1:1, put them into 10mL N,N dimethylformamide solution and magnetically stir for 12h to fully dissolve;

[0046] (2) After dissolving, use an 18G needle to squeeze the mixed solution into deionized water, soak at room temperature and let stand for 12 hours;

[0047] (3) Place the soaked sample in 1mol L -1 Soak in the potassium hydroxide solution at room temperature for 12 hours;

[0048] (4) Take out the fibers and put them in the refrigerator to freeze at -18°C for 12 hours, and finally take out the samples and put them in a vacuum freeze dryer, and freeze them at -55°C for 16 hours.

[0049] (5) The freeze-dried sample was put into a tube furnace for calcination, and was heated at 1°C min in an air atmosphere. -1 The temperature was raised to 270°C at a spee...

Embodiment 2

[0058] The difference between this example and Example 1 is that in step (1), the polyacrylonitrile macromolecule and polyvinylpyrrolidone macromolecular mass are weighed to be 0.5g and 0.5g respectively;

Embodiment 3

[0060] The difference between this example and Example 1 is that in the step (1), the polymer weights of polyacrylonitrile and polyvinylpyrrolidone are weighed to be 0.7 g and 0.35 g respectively. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com