Preparation process and dyeing process of nanometer liquid black

A preparation process and nanotechnology, applied in dyeing, textile and papermaking, etc., can solve the problems of low energy consumption, complicated procedures, large water consumption, etc., and achieve good color fixing effect, strong dyeability and good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation technology of nanometer liquid black, comprises the following steps:

[0031] A, adopt 30% nitric acid solution to carry out oxidative modification to carbon black surface, obtain oxidized carbon black after 45 ℃ of drying;

[0032] B, after oxidized carbon black and lignin sodium carbonate are mixed and dissolved with 8 times of deionized water, process 22min through 1250W ultrasonic cell pulverizer, obtain nanometer oxidized carbon black dispersion liquid;

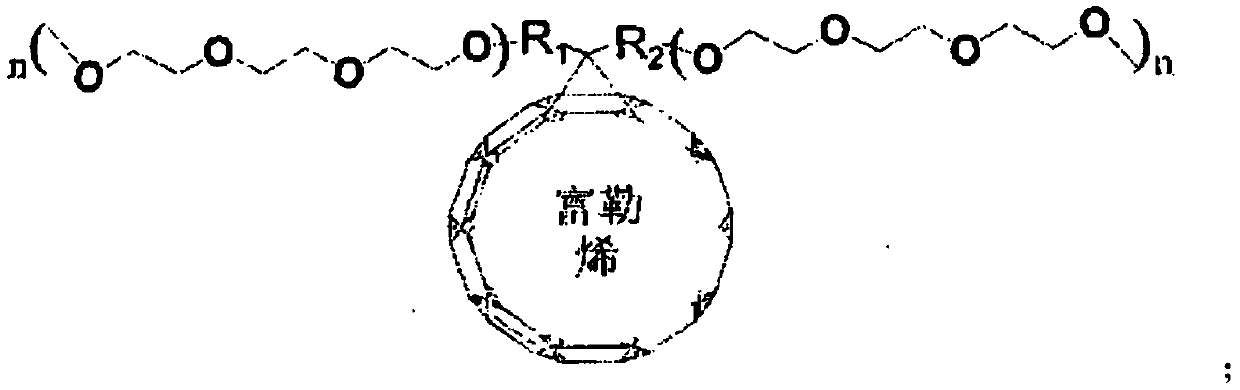

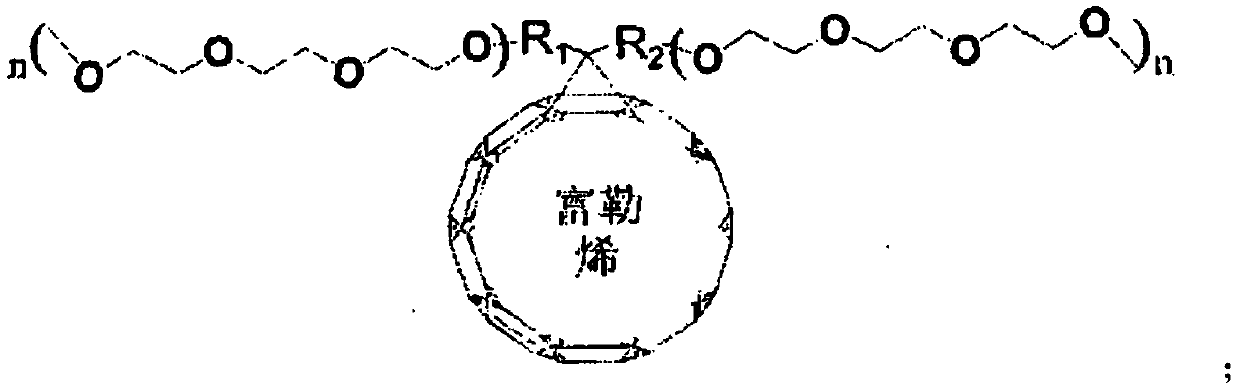

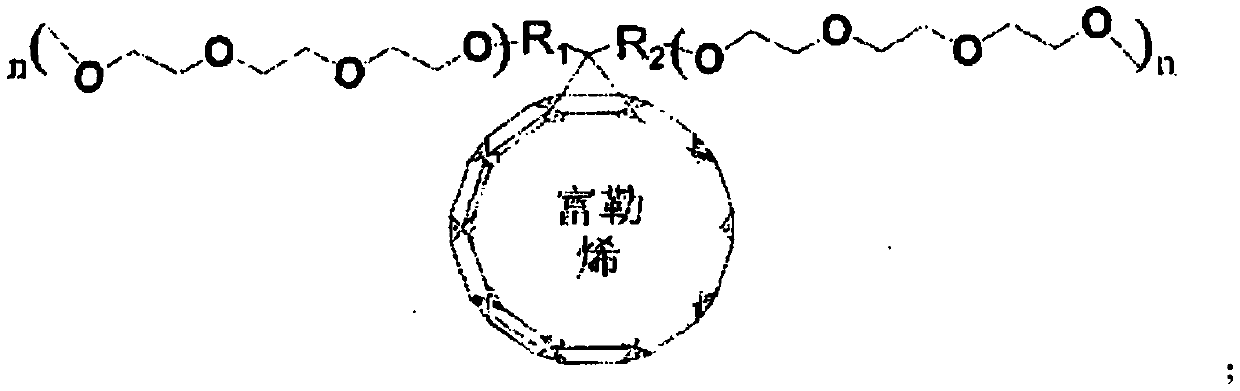

[0033] C. Add hydrophilic fullerene derivatives and silane coupling agent KH570 to the nano-oxidized carbon black dispersion, heat to 68°C and perform 650W ultrasonic dispersion for 35 minutes, add quaternary ammonium salt emulsifier and silicone defoamer , and mix evenly to get nano liquid black.

[0034] In the step A, the mass ratio of the liquid-phase oxidant to carbon black is 35:1.

[0035] In the step B, the mass ratio of the lignin sodium carbonate to the oxidized carbon black is 1:...

Embodiment 2

[0038] A kind of preparation technology of nanometer liquid black, comprises the following steps:

[0039] A, adopt 32% hydrogen peroxide solution to carry out oxidative modification to carbon black surface, obtain oxidized carbon black after 40 ℃ of drying;

[0040] B, after oxidized carbon black and lignin sodium carbonate are mixed and dissolved with 10 times of deionized water, process 25min through 1200W ultrasonic cell pulverizer, obtain nanometer oxidized carbon black dispersion liquid;

[0041] C. Add hydrophilic fullerene derivatives and silane coupling agent KH590 to the nano-oxidized carbon black dispersion, heat to 60°C and perform 800W ultrasonic dispersion for 30min, add quaternary ammonium salt emulsifier and silicone defoamer , and mix evenly to get nano liquid black.

[0042] In the step A, the mass ratio of the liquid-phase oxidant to carbon black is 50:1.

[0043] In the step B, the mass ratio of the lignin sodium carbonate to the oxidized carbon black is ...

Embodiment 3

[0046] A kind of preparation technology of nanometer liquid black, comprises the following steps:

[0047] A, adopt 30% nitric acid solution to carry out oxidative modification to carbon black surface, obtain oxidized carbon black after drying at 50 ℃;

[0048] B, after oxidized carbon black and lignin sodium carbonate are mixed and dissolved with 5 times of deionized water, process 15min through 1500W ultrasonic cell pulverizer, obtain nanometer oxidized carbon black dispersion liquid;

[0049] C. Add hydrophilic fullerene derivatives and silane coupling agent KH570 to the nano-oxidized carbon black dispersion, heat to 70°C and perform 500W ultrasonic dispersion for 40min, add quaternary ammonium salt emulsifier and silicone defoamer , and mix evenly to get nano liquid black.

[0050] In the step A, the mass ratio of the liquid-phase oxidant to carbon black is 8:1.

[0051] In the step B, the mass ratio of the lignin sodium carbonate to the oxidized carbon black is 1:120. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com