Preparation method of high-performance sintered neodymium-iron-boron magnet

A NdFeB, high-performance technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of magnet performance degradation, neodymium-rich phase purge outflow, etc., to improve coercive force, good Economic benefits, effects of enhanced remanence and maximum energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a high-performance sintered NdFeB magnet, comprising the following steps:

[0032] NdFeB Alloy Micropowder (PrNd) Prepared by Vacuum Rapid Solidification and Hydrogen Breaking Process 30.1 Cu 0.2 Ga 0.2 co 0.5 al 0.2 Zr 0.2 Nb 0.1 Fe 67.7 B 0.8; Add 1.2wt% lubricant (tributyl borate), 1.2wt% antioxidant (organic esters and aviation gasoline mixture), 0.5wt% dispersant (polyethylene glycol) mixed in the prepared alloy powder Material 2h; Put the mixed raw material into jet mill powder, the average particle size is 3 μm, add 0.2wt% lubricant (tributyl borate) then, mix material 2h; The magnetic powder after the material mixing is in the magnetic field of magnetic field strength 2T Orientation in the middle, and press molding at the same time, the magnetic field direction of the magnetic field is perpendicular to the pressure direction of the press molding, and the blank after pressing is processed by cold isostatic pressing to obtain a green...

Embodiment 2

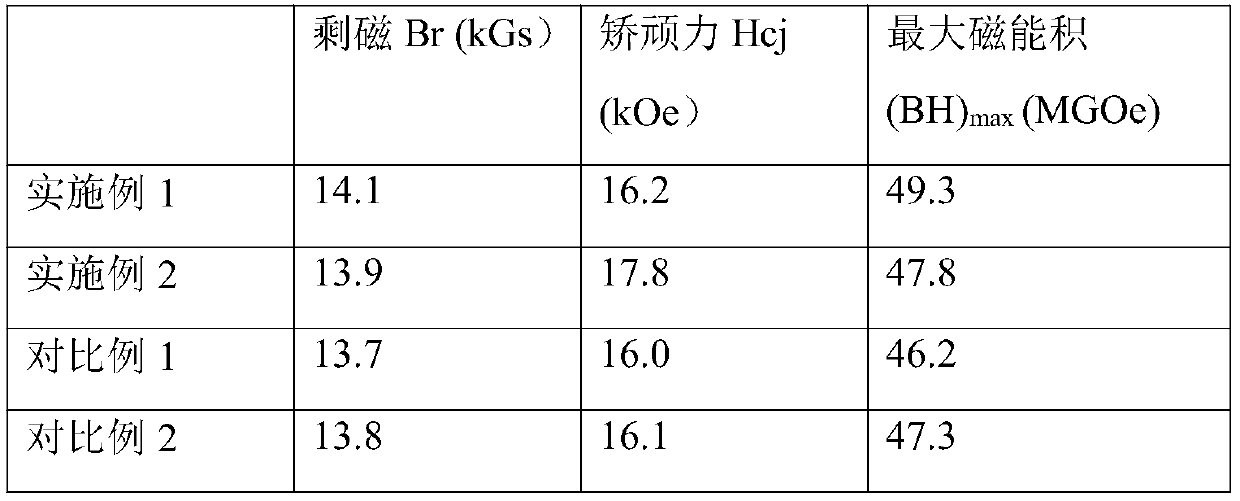

[0034] The NdFeB alloy micropowder in this Example 2 is the same as in Example 1, and the other preparation process conditions remain the same, the only difference is that the sintering temperature in the high temperature sintering process is 1050 ° C, the sintered NdFeB magnet obtained in this Example 2 Room temperature performance: remanence Br=13.9kGs, maximum energy product (BH)max=47.8MGOe, coercive force Hcj=17.8kOe.

Embodiment 3

[0045] A method for preparing a high-performance sintered NdFeB magnet, comprising the following steps:

[0046] Nd-Fe-B Alloy Micropowder Nd Prepared by Vacuum Rapid Solidification and Hydrogen Breaking Process 23.5 PR 7 Dy 0.5 Ga 0.1 co 1 Al 0.1 Zr 0. 2 Cu 0.1 Fe 66.63 B 0.97 ; Add 0.8wt% lubricant (tributyl borate), 0.75wt% antioxidant (organic esters and aviation gasoline mixture), 1.2wt% dispersant (polyethylene glycol) compound in the prepared alloy powder 3h; put the mixed fine powder into the jet mill to make powder, the average particle size is 3μm, then add 0.2wt% lubricant (tributyl borate), and mix the material for 3h; firstly apply the reverse magnetic field 2T to the magnetic powder, and then apply the positive direction Magnetic field 2T, apply reverse magnetic field 6 times, then press molding, the magnetic field direction of described magnetic field is perpendicular to the pressure direction of press molding, and the billet after pressing molding is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Maximum energy product | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com