Preparation method of slowly digestible starch

A technology of slow-digesting starch and starch milk, which is used in medical preparations, pharmaceutical formulations, and food ingredients that are not active ingredients as odor modifiers, etc. and other problems to achieve the effect of improving flavor, increasing slowly digestible starch content, and avoiding the use of acid-base reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Dry heat amorphization: Weigh 1000g of rice starch for dry heat amorphization treatment, set the temperature at 145°C for 10 minutes, add water to prepare a concentration of 35% (w / w, the dry base of starch accounts for the total amount of starch milk) Quality) starch milk;

[0038] (2) Amino acid complexation: Add glutamic acid to the dry heat amorphized starch milk in an amount of 7% of the total mass of the starch milk. Complexation was performed by phacoemulsification, and the time of sonication was 30 min. Set the ultrasonic working frequency to 30kHz, the processing power to 800W, and the temperature to 55°C;

[0039] (3) Centrifugal dehydration: the rice starch-glutamic acid complex obtained by ultrasonication in step (2) is centrifuged and dehydrated to obtain a precipitate; the moisture content of the complex is reduced from about 58% to 35%. Set the centrifugal speed to 5000rpm, and the centrifugal time to 15min;

[0040] (4) Crystallization conversion:...

Embodiment 2

[0044](1) Dry heat amorphization: Weigh 1000g of rice starch for dry heat amorphization treatment, set the temperature at 145°C for 10 minutes, add water to prepare a concentration of 35% (w / w, the dry base of starch accounts for the total amount of starch milk) Quality) starch milk;

[0045] (2) Amino acid complexation: first dissolve and disperse leucine with dehydrated alcohol, the consumption of dehydrated alcohol is 0.01 times of the volume of starch milk, and the amount of leucine added is 7% of the total mass of starch milk. The dissolved and dispersed leucine was added to the dry heat amorphized starch milk. Complexation was performed by phacoemulsification, and the time of sonication was 30 min. Set the ultrasonic working frequency to 30kHz, the processing power to 800W, and the temperature to 55°C;

[0046] (3) Centrifugal dehydration: the rice starch-leucine complex obtained by ultrasonication in step (2) is centrifuged and dehydrated to obtain a precipitate; the ...

Embodiment 3

[0051] (1) dry heat amorphization: same as Example 1;

[0052] (2) Amino acid complexation: complexation is carried out by phacoemulsification, the ultrasonic operating frequency is adjusted from 30kHz to 40kHz, and other operating conditions are the same as in Example 1;

[0053] (3) to (5) are the same as in Example 1.

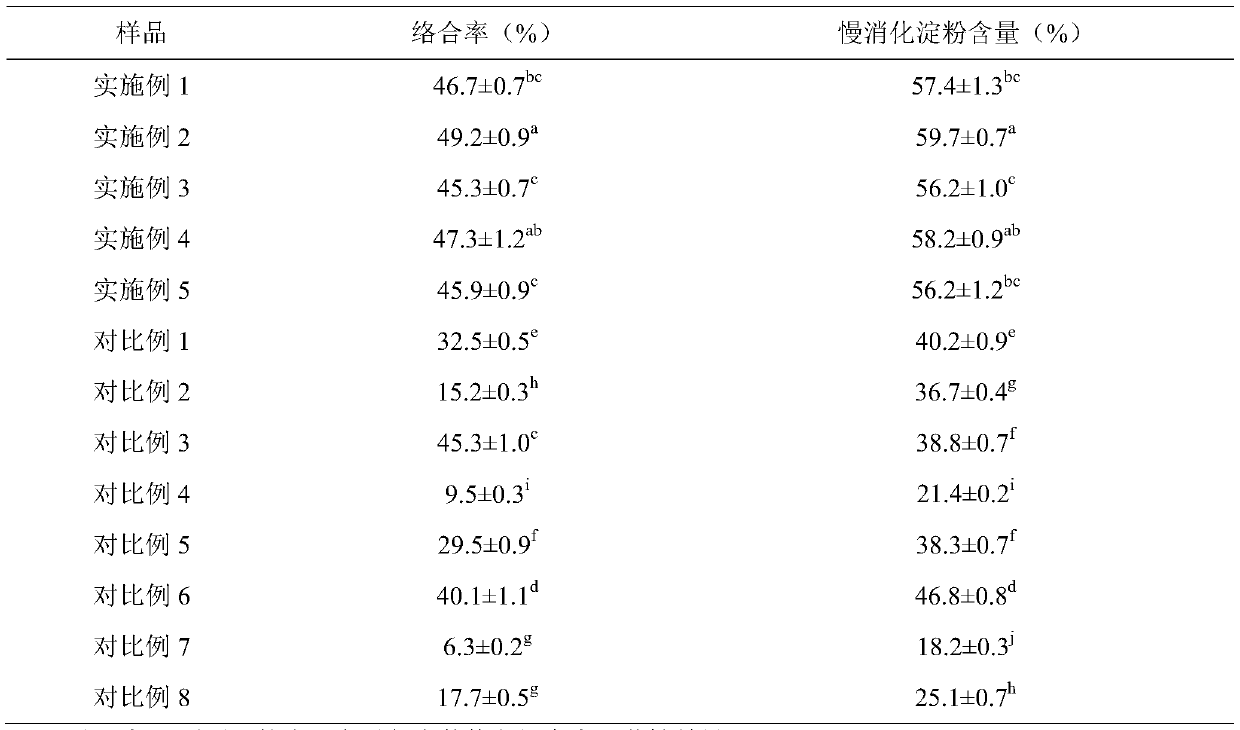

[0054] The starch-amino acid complexation rate of the product obtained in step (5) is determined by iodine colorimetry to reach 45.3%; the content of slowly digested starch measured by Englyst method reaches 56.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com